TM 5-6115-465-12

TO 35C2-3-446-1

NAVFAC P-8-625-12

TM 06858B/06859D-12

.

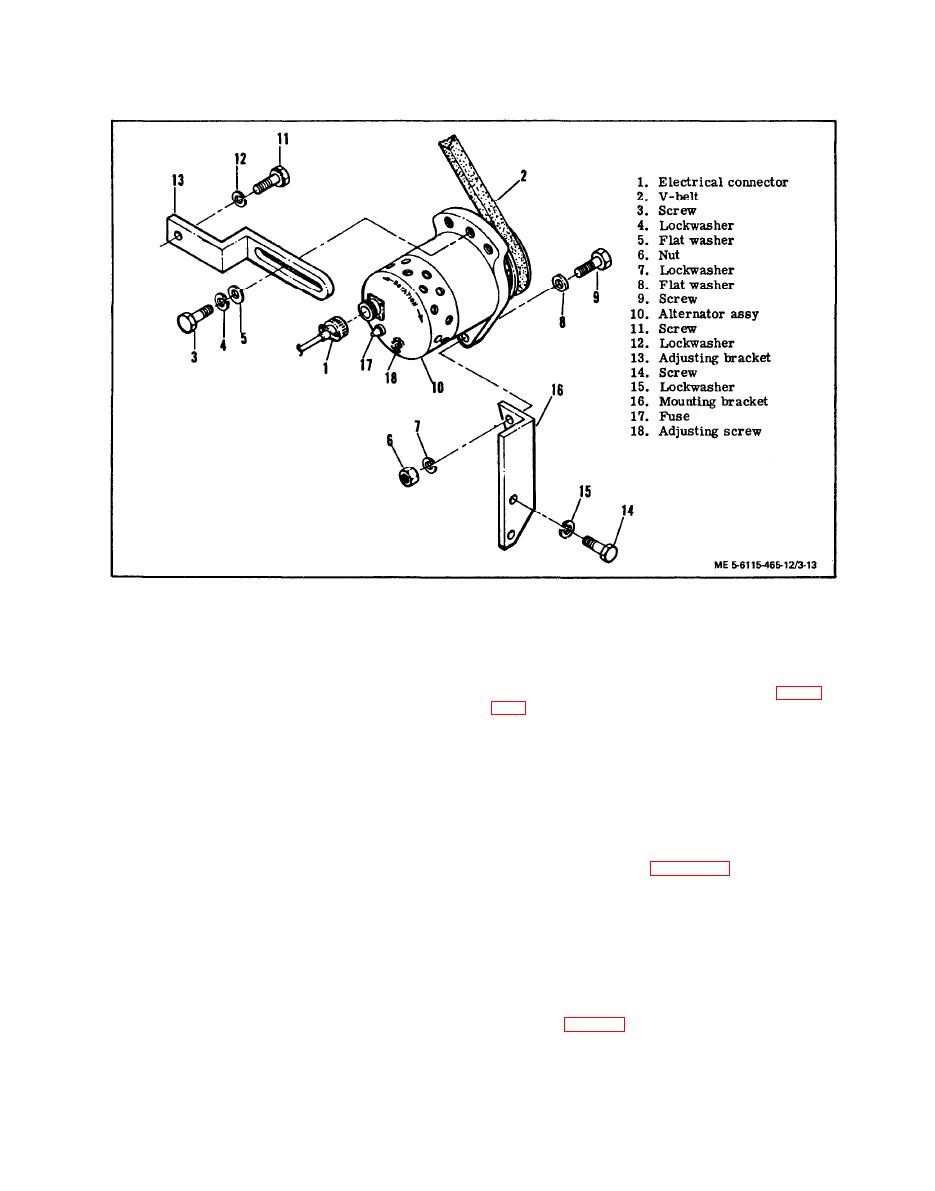

Figure 3-13.

Battery Charging Alternator Removal and Installation

(d) Attach a No. 10 ring terminal to one

(1) Clean alternator with dry, filtered, com-

end of the 5 inch wire.

pressed air and a soft bristle brush or wipe with a

clean, lint-free cloth lightly moistened with an

approved solvent.

(4) Attach the test leads as shown in figure

(2) Inspect alternator for cracks, corrosion,

hole in the ventilated shield of the alternator housing.

evidence of shorting and overheating, bent or

broken connector pins and other damage.

(5) Carefully install the rear cover plate and

secure with screws.

c.

Testing and Adjustment.

(6) If alternator is still installed in the gen-

(1) Remove four screws attaching the rear

erator set, connect wiring harness comector to the

cover plate to the alternator.

(2) Carefully pull the cover plate away from

(7) If alternator has been removed, install it

the alternator assembly.

in test setup as shown in figure 3-15 and provide a

means of rotation at approximately 2500 rpm.

(3) Fabricate two test leads as follows:

(8) Place multimeter selector tn the 50 Vdc

(a) Cut two pieces of No. 8 or No. 10 in-

position.

sulated wire; one 5 inches long and the ether 10

inches long.

(9) Operate alternator at the required rpm

and note the reading on the multimeter.

(b) Strip both ends of each wire and tin

with solder (Federal Specification QQ-S-571).

(10) If multimeter reading is not in accor-

(c) Attach a No. 10 ring terminal to one

dance with table 3-5, rotate adjusting screw to ob-

end of the 10 inch test lead.

tain proper reading.

Change 5

3-34.5/(3-34.6

blank)