TM 5-6115-400-35

CHAPTER 4

MAIN GENERATOR AND AUXILIARY EQUIPMENT

REPAIR INSTRUCTIONS

Section I. MAIN GENERATOR

64. General

The Electric Machinery Model 651853 alternating

current generator is a fully enclosed, fan-cooled,

revolving field, 3-phase alternator. The generator rotor

is driven directly by the engine flywheel through a

flexible coupling.

When driven at its rated speed of 1,800 rpm, the

generator will produce 200 KW (kilowatt) at 60 cycles

with a power factor of 0.8 and it will deliver 694 amperes

at 120/208 volts or 347 amperes at 240/416 volts.

When driven at 1,500 rpm, the generator will produce

167 KW at 50 cycles with a power factor of 0.8 and it

will deliver 580 amperes at 120/208 volts or 290

amperes at 240/416 volts.

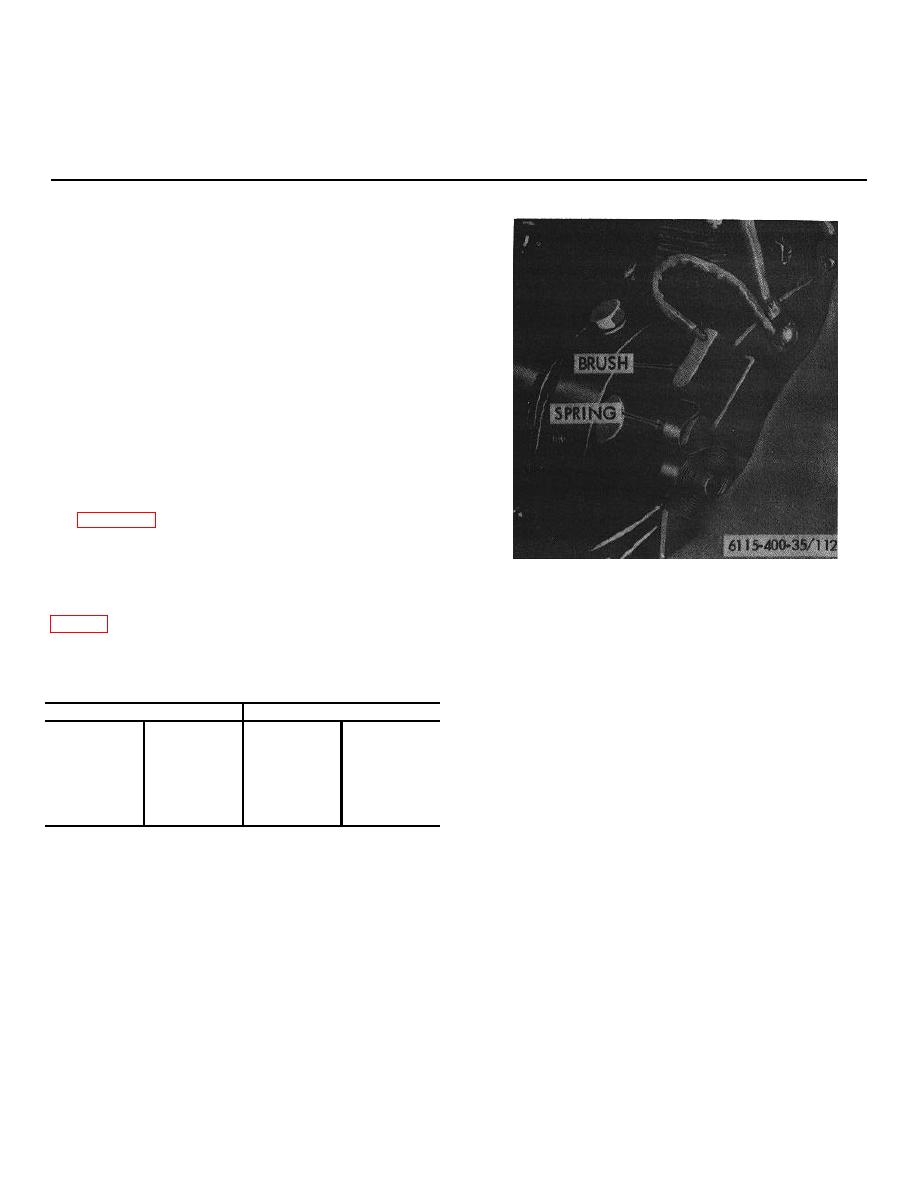

65. Brush Tension Adjustment

Adjust the brush springs to obtain a brush tension

between 15 ounces minimum to 24 ounces maximum.

See figure 112.

66. Drying Out Generator Windings

a. If the generator set has been subjected to extreme

Figure 112. Brush tension adjustment.

dampness, a preliminary period of operation may be

required to thoroughly dry all generator windings. Use a

Note

megger to determine if drying out is necessary. Refer to

Before measuring the resistance of

the generator stator and rotor,

rotor.

disconnect all controls. Do not use a

Table 3. Insulation Limits

megger to check the rectifiers and

Minimum values when insulation resistance is taken at

other components installed in the

various ambient temperatures:

voltage regulator and excitation unit.

Stator

Rotor

b. To dry out the generator windings, first

Ambient

*Megohms

Ambient

*Megohms

15

C

39

15

C

58

brushes and connect an external source of field

20

C

32

20

C

47

excitation direct current to the brushes. Short circuit the

25

C

27

25

C

39

stator terminals and insert a current transformer and

30

C

22

30

C

32

ammeter, capable of reading full-load generator current,

35

C

18

35

C

27

in one of the shorting leads. Operate the generator at

*The megged values should equal or exceed the figures

rated speed (1,800 rpm) and apply sufficient field

given for the temperatures at the time of test.

excitation to develop rated full load stator current.

Operate under these conditions for sufficient time to

insure thorough drying of the windings as determined by

periodic measurements of rotor and stator insulation

resistance.

145