TM 9-6115-604-34

NAVFAC P-8-633-34

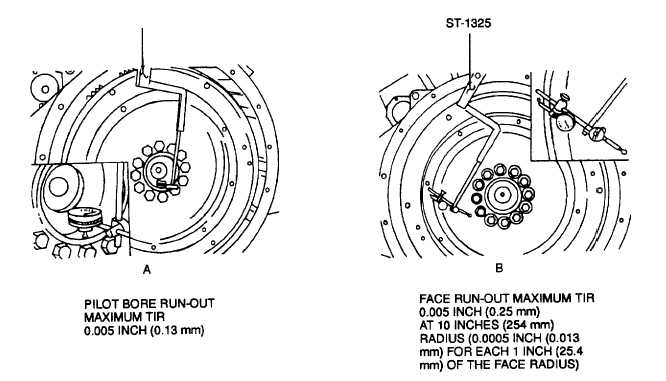

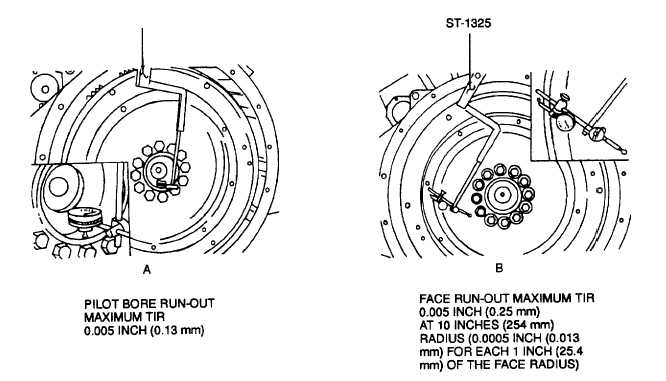

Figure 9-64. Checking Flywheel Runout

9-35. FLYWHEEL AND REAR GEAR HOUSING MAINTENANCE.

a.

Inspect Installed Housings.

(1)

Visually inspect the flywheel housing (9, Figure 9-62) and rear gear housing (32) for cracks. Replace any

cracked housing or housings in accordance with steps b and d, below.

(2)

If housing misalignment is suspected, check the alignment in accordance with step d(1 4), below.

(3)

If cracks or other physical damage is suspected, remove and inspect the housing in accordance with step

(c), below.

b.

Remove.

(1)

Remove the flywheel in accordance with paragraph 9-34.

(2)

Remove the starter motors in accordance with the Operator and Organizational Maintenance Manual.

WARNING

The weight of the flywheel housing Is approximately 385 pounds (173 kg). Use of a lifting

device not rated for this weight may result In damage to components or Injury to personnel.

(3)

Bolt a sling to the flywheel housing (9, Figure 9-62) at the 10 and 2 O'clock positions, attach to an

overhead hoist, and take up slack in the sling and hoist.

(4)

Remove the capscrews (6 and 7) and lockwashers (8) from the flywheel housing (9).

(5)

Using the sling and hoist, remove the flywheel housing (9) by tapping it free of the dowels (11) using a soft

hammer. Remove and discard the dust seal (10), and remove the dowels if damaged.

(6)

Remove the capscrews (12), lockwashers (13), and flange cover (14).

(7)

Remove the capscrews (1 5), lockwashers (1 6), and remove the barring device housing (17) and attached

parts.

(8)

Remove the cotter damp (18), retaining ring (19), and remove the spring (20), gear (21), lock key (22), and

shaft (23) from the barring device housing (17). Remove and discard the packing (24) from the shaft (23).

(9)

Remove the rear crankshaft seal and retainer in accordance with paragraph 9-33.

9-113