TM 9-6115-604-34

NAVFAC P-8-633-34

(25)

Set the counterweights on the grinding machine back to 0 to balance the crankshaft.

(26)

Using a dial indicator, set up the front and rear main journals to be on center within 0.001 inch (0.03 mm)

TIR.

NOTE

Relaxing of residual stress as the crankshaft is ground will sometimes cause a crankshaft to

"bow" in misalignment. If the following check shows the runout to be over 0.002 inch (0.05 mm),

straighten the crankshaft in accordance with step e, above.

(27)

Check the runout of the center main bearing journal. if the TIR is 0.002 inch (0.05 mm) or less, move the

front and rear main bearing journals slightly off center to split the runout with that of the middle journal.

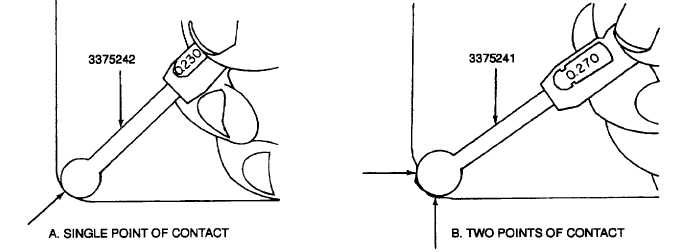

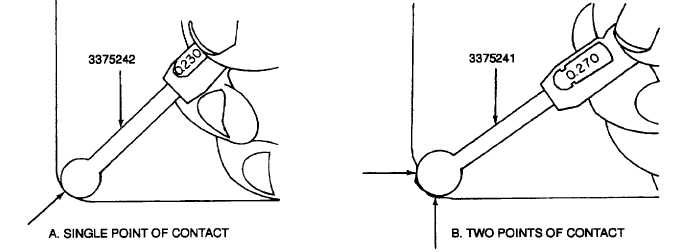

Figure 9-52. Checking Fillet Radius

NOTE

It is preferable to grind the center main bearing journal first. If some other main bearing journal

is damaged raising a question as to what undersize is necessary, support the center main

bearing journal while the damaged main journal is ground. Before installing the steady rest, the

center main bearing journal should be touched with the grinding wheel to dean up and remove

any out-of-roundness in the journal. With the indicator set up to show runout and the crankshaft

turning slowly, apply support pressure with the steady rest until the indicator shows only the

residual out-of-roundness of not more than 0.0001 to 0.0002 inch (0.003 to 0.005 mm).

Application of support pressure beyond this point will not further reduce runout, but will push

the main bearing journal off center, and cause a taper to be ground in the remaining main

bearing journals.

(28)

Measure the main bearing journal to determine what standard undersize is required (Figure 9-41). If the

journal is worn 0.001 inch (0.03 mm), for example, then 0.009 inch (0.23 mm) must be removed to bring the

main bearing journal to 0.010 inch (0.25 mm) undersize.

(29)

Start the crankshaft rotating and start the grinding wheel. Then, turn on the coolant and adjust the steady

rests to support the crankshaft.

NOTE

Journal width is not as critical on main bearing journals and there is very little wear on these

surfaces. Usually only a very light grind on the side wall is necessary to dean up the surface, but

make certain that the fillet area is being ground sufficiently to be smoothly blended.

(30)

Center the wheel on the main bearing journal, and carefully feed the wheel in until it just touches the journal.

Then traverse the wheel to one side until the wheel just starts grinding the fillet. Allow the grinding wheel to

remove any out-of-roundness in the journal.

9-91