TM 9-6115-604-34

NAVFAC P-8-633-34

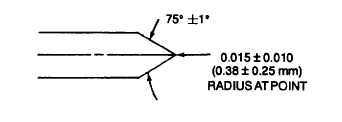

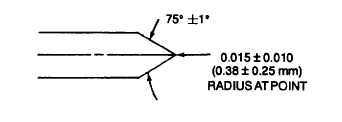

Figure 9-48. Wheel Dressing Tool

(b)

Clamp the wheel dressing tool into position on the grinding machine.

(c)

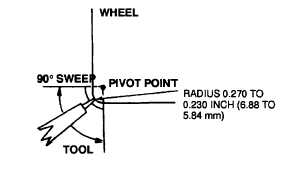

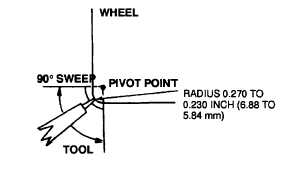

Adjust the diamond in the wheel dressing tool to form a radius of 0.270 to 0.230 inch (6.88 to 5.84 mm)

on the grinding wheel edges (Figure 9-49).

(d)

Bring the grinding wheel dose to the dressing tool, align it with the center of the wheel, turn on the

coolant, and start the grinding wheel.

NOTE

The speed at which the grinding wheel is fed across the wheel dressing tool will determine the

surface finish on the crankshaft journal. A slow rate of feed will produce a finer surface finish

than a fast rate of feed. Do not feed too slowly; a wheel surface that is too fine will increase the

risk of grinder bum damage to the crankshaft journal.

(e)

Feed the wheel into the dressing tool approximately 0.001 to 0.003 inch (0.03 to 0.08 mm) and

traverse the wheel across the dressing tool.

(f)

Repeat step (e), above, until smooth and true grinding wheel surface is produced.

(g)

After making the final cut, set the index on the feed to 0. This will bring the wheel back to the same

position for dressing the radii of the wheel.

(h)

Back the wheel out approximately 0.002 inch (0.05 mm) and install pins in the dressing fixture to

provide an exact 90 degree sweep of the tool.

(i)

Starting with the tool on the side of the wheel, traverse the wheel over until it just contacts the tool, and

lock the traverse in this position.

(j)

To dress the radius, slowly pivot the tool around the wheel until it contacts the stop. Leave the tool in

this position.

(k)

Feed the wheel in 0.0005 inch (0.013 mm), and make another cut on the radius. Continue to feed the

wheel in 0.0005 inch (0.013 mm) at a time, and dress the radius until the wheel reaches the 0 set point

of step (g), above. At this point, the radius should be smooth and properly blended with the side and

face of the wheel.

(I)

Back the wheel out, and dress the other radius of the wheel in accordance with steps (i), a), and (k),

above.

(m)

Back the wheel out, turn off the coolant, and remove the dressing tool.

Figure 9-49. Grinding Wheel Edge Radius

9-86