TM 9-6115-604-34

NAVFAC P-8-633-34

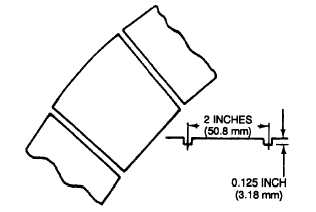

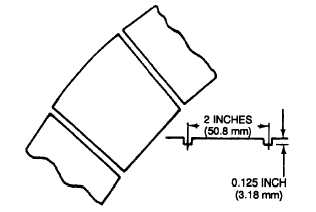

Figure 9-46. Grooved Sidewall Grinding Wheel

(a) Use a grooved grinding wheel to specifications 6A-60K6-V22. Each side wall of the wheel shall have

radial grooves approximately 0.125 inch (3.18 m) deep and spaced about 2 inches (50.8 mm) apart at

the face (Figure 946). The grooves help prevent grinding wheel loading, and effectively reduce grinding

temperatures.

(b) The wheel guard must have an efficient air baffle and side washer equipment (Figure 9-47). Grinding

wheels are porous and centrifugal forces tend to pump air through the wheel and blow the coolant away

from the grinding area. The air baffles and side washers supply coolant to displace the air being pumped

through the wheel.

(c) The grinding machine coolant flow must be sufficient to supply the side washers and main jet with an

ample volume of coolant.

(d) The procedural steps, that must be observed to reduce the risk of grinder bum damage are as follows:

1

When feeding the grinding wheel into the journal bossing wall, do not exceed a feed rate of

0.001 inch (0.025 mm) per second.

2

The grinding wheel surface speed shall be 6500 feet (1981 m) per minute with the crankshaft

rotating at 50 rpm.

WARNING

Grinding operations create airborne, abrasive dust, and particles. Respiratory and eye protection

is required to prevent Injury to personnel.

(2)

Dress grinding wheel. Dress the radii of the grinding wheel to blend smoothly with the sides and face of the

wheel. Failure to properly dress the radii will result in a small barely visible groove in the wheel. This will

form a stress riser in the journal that can lead to breakage of the shaft. Dress the grinding wheel as follows:

(a)

Use an industrial diamond in the wheel dresser that has been lapped to a cone having a 75 degrees

included angle with a point radius of 0 .005 to 0.025 inch (0.001 to 0.64 mm). The point of the cone is

to be on the centerline of the shank (Figure 9-48).

NOTE

The point of the diamond must be on a radial line from the pivot center of the dressing device so

that the radii generated on the grinding wheel will blend smoothly to both the side and face of

the wheel. The dressing tool must have stops to limit the travel of the diamond point to exactly

90 degrees to the face and sides of the wheel (Figure 9-49).

9-84