TM 9-6115-604-34

NAVFAC P-8-633-34

9-16. CAMSHAFT BUSHINGS REPLACEMENT.

a.

Inspect

(1)

Remove the camshafts in accordance with paragraph 9-15.

(2)

Visually inspect the camshaft bushings for burning, flaking, galling, grooving, pitting, or scoring.

(3)

if the bushings show evidence of burning, flaking, galling, or grooving, replace them in accordance with

steps b and c, below.

(4)

If bushings are pitted or scored in excess of 0.002 inch (0.05 mm) deep, replace them in accordance with

steps b and c, below.

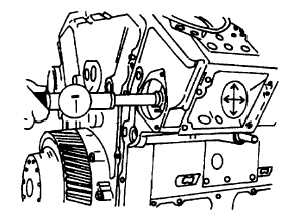

Figure 9-17. Measuring Camshaft Bushing Bore

(5)

Using an inside micrometer, or dial bore gage, measure the bore diameter of the bushings in both a

vertical and horizontal plane (Figure 9-17).

(6)

Replace the bushings in accordance with steps band c, below, if the maximum diameter is beyond the

limits given in Table 1-4.

b.

Remove.

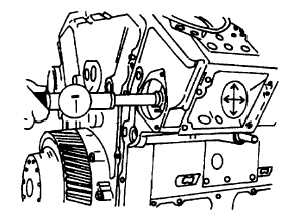

(1)

Assemble the camshaft bushing driver set ST-1228 (Figure 9-18) using the slide hammer, rod, mandrel,

extension shaft, guide, and driver as follows:

(a)

Install the guide in the bushing bore at the rear of the engine.

(b)

Assemble the mandrel and extension shaft and insert them through the guide with the mandrel

toward the front of the engine. Push the mandrel and the extension shaft through the guide until the

end of the mandrel is in the front cam follower opening.

(c)

Install the driver on the mandrel and position the driver in the front camshaft bushing (28, Figure 9-

15).

(d)

Install the rod (Figure 9-18) and slide hammer in the extension shaft.

(2)

Using the slide hammer, drive the front camshaft bushing (28, Figure 9-15) out of the engine block.

(3)

Remove the driver (Figure 9-18) from the mandrel, reposition the driver and mandrel behind the next

bushing, and drive out the bushing as in step (2), above.

(4)

Repeat step (3), above, until the bushings have been removed from the front half of the engine.

(5)

Reverse the driver set so that the guide is in the front bushing bore and the driver is positioned in the rear

bushing, and remove the bushings from the rear half of the engine in accordance with steps (2) and (3),

above.

(6)

If any bushing drove out easily, or shows signs of rotation in the bore, measure the bore diameter. If the

bore diameter is over 3.1895 inch (81.013 mm), sleeve the bore in accordance with paragraph 9-31.

9-35