TM 5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

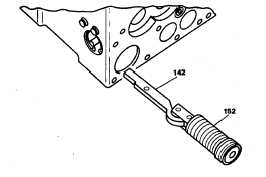

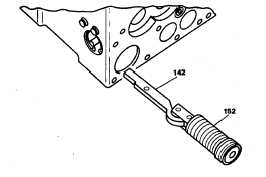

Figure 12-15. Power Piston Assembly

valve plunger is centered, tighten nut (84),

figure 12-22, to 70 inch-pounds (8 joules).

(20)

Lubricate base oil seal (118, figure 12-24) and

place it in groove on base. Line up pins (107).

Assembly base to case and secure it with

lockwashers (106) and screws (105). Check

bushing rotation for freeness before tightening

screws.

(21)

Assembly transducer cup (75), transducer

solenoid (76), washer (77), magnet (78), and

coil cover (79). See figure 12-25. Plug (51) is

attached to the transducer.

(22)

Install transducer assembly on pilot valve

plunger and attaching plug (51) to case with

screws (50). Be sure connections of plug (51)

match the connections in cover.

(23)

Install clamp bracket assembly (74, figure 12-3)

with screws (65) and lockwasher (66). Line up

guide pin on bracket (74) with slot in link (83).

Insert centering screw (63) through hollow

center of adjustable spring seat (64). Bottom

centering screw to prevent binding when plate

(70) is installed. Final adjustment is made later.

(24)

Insert transducer compression spring (57) in

position and pivot the transducer lever over to

lie on top of the spring. Attach plate (70) to

restoring lever with

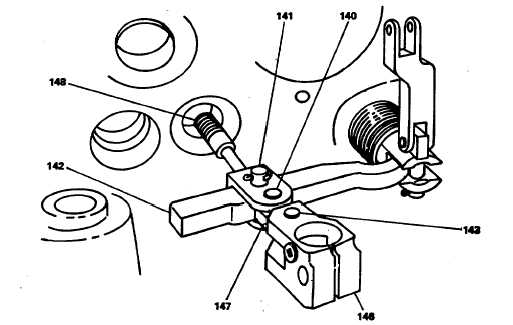

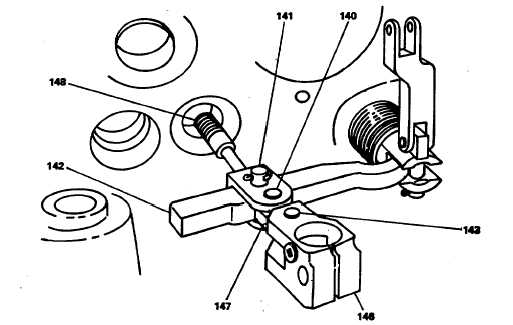

Figure 12-16. Power Piston and Linkage Installation

12-15