TM5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-456-2

(3) Testing Field Coils. See Operator and

Organizational Maintenance Manual.

(4) Testing Brushes.

See Operator and

Organizational Maintenance Manual.

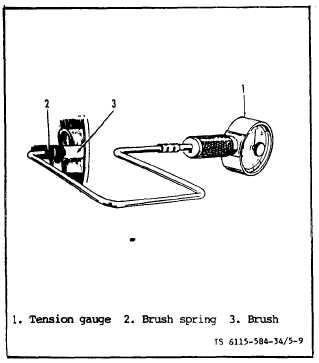

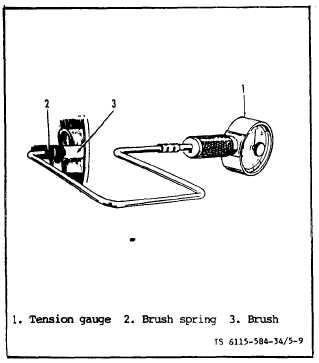

(5) Testing Brush Springs. Style I Starter.

(see figure 5-9).

Measure brush spring with tension meter. Push the

brush and take reading just as the brush projects

a little from the brush holder. On a new brush,

the spring tension should be 32 to 40 ounces. If

brush spring tension is below 20 ounces, replace

it.

Figure 5-9. Testing Brush Spring Tension

STYLE I Starter Only.

(6) Testing Brush Springs. Style II Starter.

Firmly hold brush holder and push the brush

against the brush spring until completely inside

of its guide. If little or no resistance (tension)

is present, spring should be replaced. Badly worn

or pitted brush surface may indicate weak spring.

(7) Testing Solenoid Switch. Style I Starter.

(b) Measure the hold-in current using

Test B, figure 5-10. Current should not exceed 6

amps.

(c) Check total hold and pull current

draw using Test C, figure 5-10. Total current

should not exceed 25 amps. Replace defective sole-

noid switch.

(8) Testing Solenoid Switch. Style II Starter.

(see figure 5-10).

(a) With solenoid on starter, push the

solenoid plunger in and release it. The plunger

should return to its original position. Plunger

should slide in and out freely when push by hand.

(b) Check for continuity between terminal

“B” and terminal “M” with an ohmmeter. There

should be no continuity.

(c) Push the plunger in and hold while

checking continuity between terminal “B” and “M”.

The ohmmeter should read zero ohm with complete

continuity. If no continuity reading, the solenoid

is defective, replace it.

g. Repair

(1) Repairing Starter. Repair starter by

replacing defective components. Repair procedures

for individual components are as follows:

(2) Repairing Armature. If the commutator

wear or runout is not excessive, (max 0.004), it

may & resurfaced as follows:

(a) Resurfacing Commutator. Place the

armature in a lathe.

Style I starters my be

turn down with a cutting tool. Style II starters

may not be turn down with a cutting tool! Only

00 or 000 sandpaper may be used on Style II and

if wear or runout cannot be corrected, the Style

II armture must be replaced! The Style I

commutator turn down may not reduce the diameter

of commutator belcw 1-1/16 inches.

(b) Undercutting Mica. After commutator

is resurfaced, undercut mica to a depth of 0.025

to 0.032 inch usina a power driven undercutting

(see figure 5-10).

(a) Check to be sure plunger moves

freely in coil. Measure pull-in coil current using

a ammeter. See Test A, figure 5-1O, current should

not exceed 16 amps.

tool.

If no power driven tool is available, the

mica may be under cut by hand. See figure

5–11.

NOTE

Use care in undercutting. Do not widen

commutator slots by removing metal from

bars, and do not leave a thin edge of mica

next to bars. Figure 5-11 illustrates good

and bad examples of undercutting. After

mica has been undercut, polish commutator

in a lathe with number 00 to 000 sandpaper

while the annature is rotating. Remove all

copper, sand and mica with compressed air.

Change 7

5-7