TM5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-456-2

(4) Remove the through studs (9), remove

screws (10) and rear cover (11).

(5) Raise the brush springs (12) lift the

brushes (13) and remove brush holder (14).

(6) Remove stator (frame assembly) (15), rear

bearing (16), armature (17) and armature front

bearing (18).

(7) Remove screws (19), cover (20),retaining

ring (21), flat washer (22) and spacer (23).

(8) Remove screw (24) freeing the center

bracket (25).

NOTE

There is a spring force behind screw (24).

(9) Remove and count the flat washers (26),

remove packing (27), outer spring (28), inner

spring (29).

NOTE

Note the direction in which the lever is

installed before removal.

(10) Remove lever (30) and gear (31).

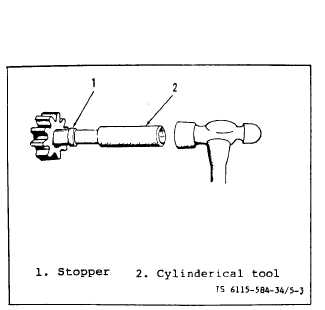

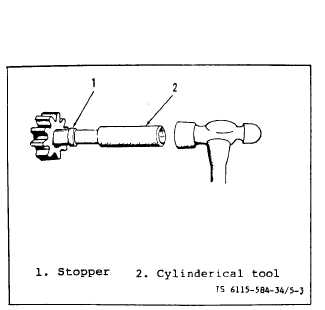

(11) Push stopper (33) towards front bracket

to release retaining ring (32). See figure 5-3.

Remove retaining rinq (32), stopper (33), pinion

gear (34)

(12)

the front

and spring(35).

Remove over running clutch (36) from

bracket assembly (37).

e. Cleaning inspection

(1) Cleaning. Clean dust off parts with

compressed air or soft brush. Remove grease and

oil with dry cleaning solvent.

Do not clean the armature or field coils

with solvent as wire insulation may be

damaged. Do not dip drive assembly or

overrunning clutch in solvent as they

are packed in grease and cannot be re-

packed. May result in premature failure.

NOTE

Pinion shaft of the overrunning clutch

must turn freely in a clockwise direction

and lock up when turned counter-clockwise.

(2) Remove discoloration or oxidation from

commutaton with fine sand paper grade 00 or 000.

Clean off sand with compressed air. Use only sand-

paper!

(3) Bearings. Inspect all bearings for wear

or damage. Replace if excessively worn or damage,

or replace back plate assembly, pinion housing, or

front bracket assembly if individual bearing is

not available.

(4) Drive Assembly. Style I Starter only.

Refer to Operator and Organizational Maintenance

Manual .

(5) Brushes. Refer to Operator and

Organizational Maintenance Manual.

(6) Solenoid Switch. Refer to Operator and

Organizational Maintenance Manual.

(7) Armature. Inspect armature for wear.

Inspect commutator for wear or runout. See test

procedure for runout. If commutator wear or

runout is not excessive, resurface according to

the repair procedures. Replace armature if it

is excessively worn or damaged.

(8) Yoke/Lever. Inspect for damage or wear,

replace if worn or damage.

(9) Frame Assembly. Inspect frame assembly

for damage. Check wires of field coil for buring

or worn insulation. Check pole shoes for tight-

ness. Check field coils for signs of armature

contact which may indicate bad bearings. Repair

or replace if damage or defective.

f. Test Bench

(1) Testing Starter. Refer to Operator and

Organization Maintenance Manual.

Figure 5-3. Pinion Gear Stopper Removal

5-4

Change 7