TM5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-456-2

(8) Slide spring (35), pinion gear (34) and

Stopper (33) onto shaft. Position retaining ring

(32) in groove on shaft and pull stopper over

ring to secure it. A bearing puller tool may

be required.

(9) Place bearings (16) and (18) on the

armature shaft, and insert armature into the

center bracket. Slide Stator (15) over armature

and into center bracket. Align stator to bracket

by fitting tab on stator into notch on center

bracket.

(10) Place brush holder (14) with brush

springs (12) in place, over the communtator of

the armature. Lift each brush spring (12) and

insert brush (13) into the guide on the brush

holder (14).

(11) Place rear cover (11) over brush holder

and against stator (15). Rotate slighly and align

threaded holes in brush holder with holes in

cover. Secure brush holder to cover with screws

(l0).

(12) Pass thru studs (9) through rear cover

(11) into tapped holes in front bracket assembly

(37) and secure.

(13) Place washers (7) on thru studs, place

terminal bracket assembly (8) on studs and add

nuts (6).

(14) Place spacers (4) on solenoid switch (5)

and align solenoid plunger slot over lever (30).

Secure solenoid and spacers to front bracket

assembly (37) with screws (3).

(15) Install field coil lead from stator (15)

onto lower threaded terminal of the solenoid (5).

Secure with nut (1) and washer (2).

J. Test after Repair/Overhaul. Style I Starter.

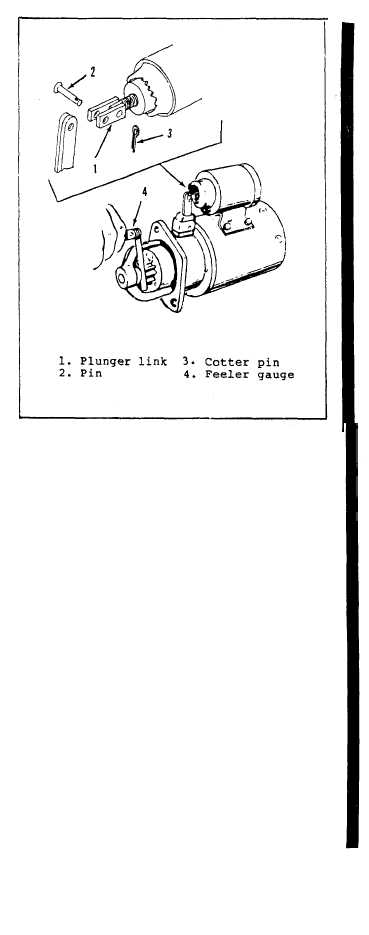

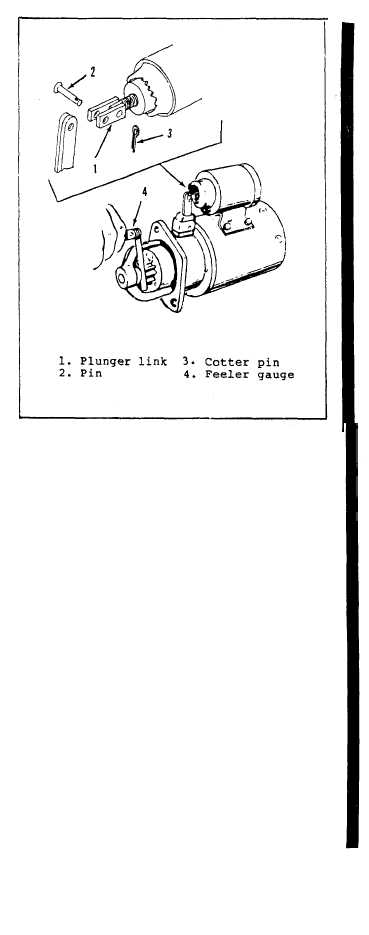

(1) After the starter is assembled, check

the armature end play by inserting thickness

gauge between thrust washer (27) and pinion

housing (28). See figure 5-1. It should be bet-

ween 0.005 and 0.035 inch. Adjust end play by

adding or removinq thrust washers (27) on the

communtator end of the Armature.

(2) Check pinion gear clearance. See figure

5-13. Proper clearance is important to insure

starter engagment. To check, press on solenoid

plunger to shift pinion gear into full mesh posi-

tion. While holding plunger in, measure clearance

with feeler gauge (4) between pinion gear and

stop. The proper clearance is 0.096 ±0.030/-0.020

inch. Adjust clearance by turning solenoid plunger

link (1) in to decrease gap, or out to increase

the gap.

See figure 5-13 cutaway view. Reinstall

the pin (2) and cotter pin (3) securing plunger

link (1) to yoke.

Figure 5-13 Checking Pinion Clearance.

STYLE I Starter

K. Test after Repair/Overhaul. Style II Starter.

(1) After starter is assembled, check the

pinion gear travel to ensure proper starter enga-

gement. See figure 5-14.

(a) To measure, provide as 24 volt DC power

source, such as battery. connect the positive "+"

battery to the solenoid terminal (S) with a

electrical lead that includes a

momentary switch.

(b) Connect the negative “-” battery ter-

minal to the ground terminal (G), with electrical

lead.

(c) Remove nut and lockwasher from terminal

(M), than remove and secure lead (L) away fran the

solenoid.

(d) Close and hold the momentary switch to

apply power to terminal (S) forcing the solenoid

plunger to pull the lever and move the pinion gear

forward. Measure the distance between mounting

surface of starter front bracket and outer edge of

pinion gear to determine the maximum travel (X).

Release the power source and the internal springs

will move lever to original position, returning

the pinion gear to its at rest position. Measure

this distance (Y). The difference between measur-

emsnt (X) and (Y) should fall within the nominal

travel distance (Z) of l7mm + or - 1mm.

Change 7

5-11