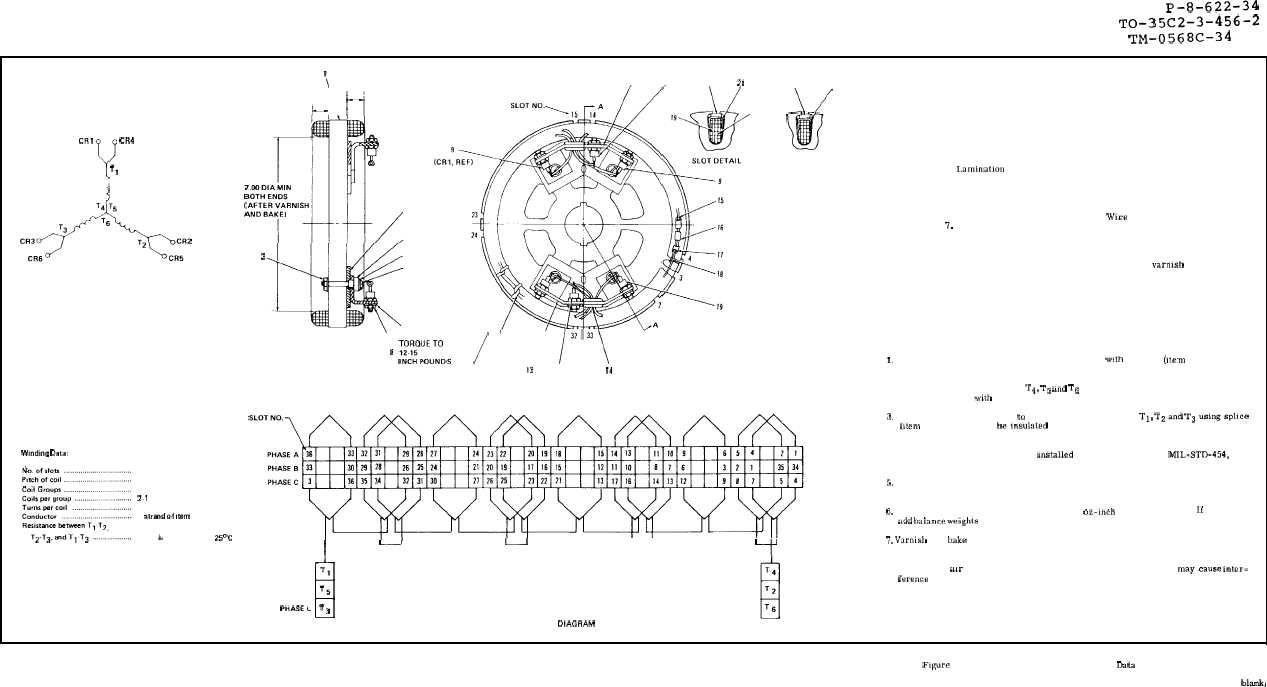

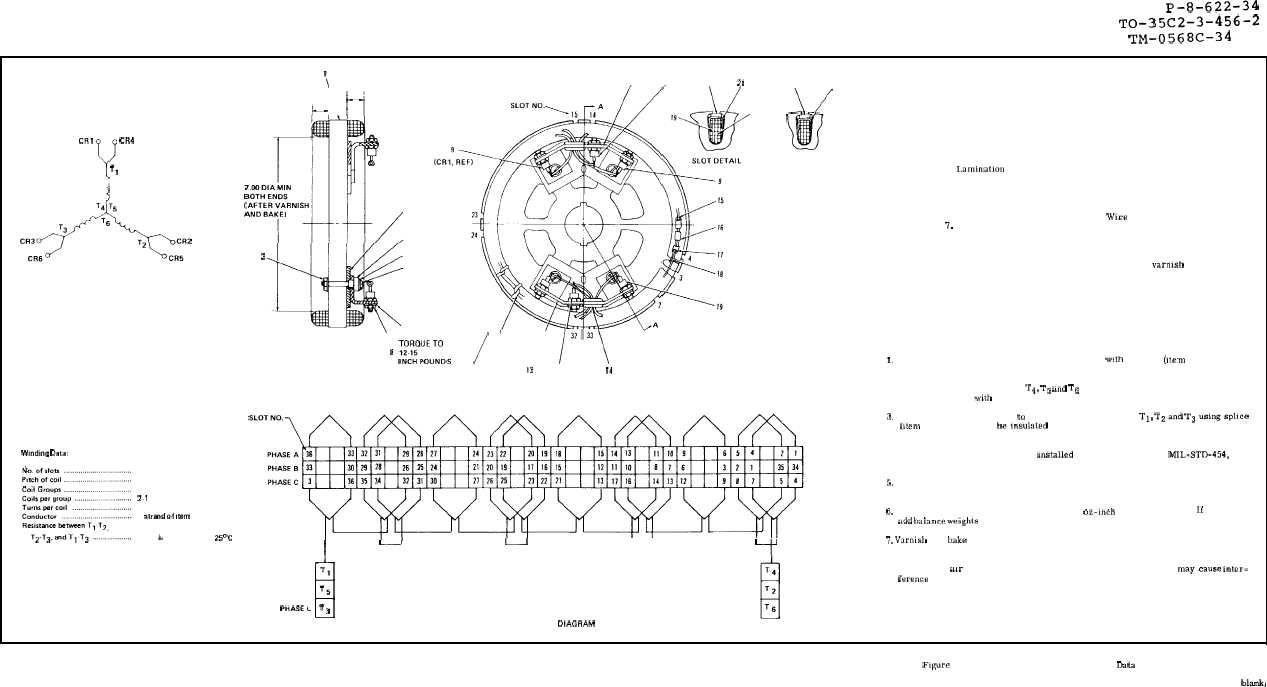

TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

TM-0568C-34

CR1

v

CR4

TI

<

CONNECTION

DIAGRAM

Wmdmg Oata:

\

II

9

20

2!

\ 1“1

.88 MAX

.88 MAX ~

3

4

TORQUE TO

15-20

2

5

INCH POUNDS

6

7

\

SECTION A-A

:::::::.s

/

/

132’33\

8

12-15

12

13

10

14

36

1-4

24

21

11

1 strand of ,mem 19

0.677 + 0.067 ohms at 25°C

.22

20

23

ti

7

SLOT DETAIL FOR

BALANCING

SCALE: 2/1

SEE NOTE 6

I

-,

d

u

Y

B

P H A S E A T,

PHASE B T5

PHASEL

T3

WINDING OIAGRAM

Legend

1. Laminatlorl assembly

2. Nut and washer assembly

3. Insulator

4. Bushing

5. Washer

6. Screw

7. Washer

8. Nut

9. Diode

10. Diode

11. Heat sink

12. Sleeving

13. Heat sink

14. Grommet

15. Wire

16. Splices

17. Insulation sleeving

18. Insulation sleeving

19. Wire (# 17 AWG magnet)

20. Wedge

21. Wedge

22. Slot insulation

23. Sheet

24. Insulating varmsh

25. Solder

NOTES

1, Winding extensions (item 19) shall be insulated with sleeving (Item 18) from slots

to splices.

2. Connect winding extensions T4, T5 and T6 together using splice (item 16). Splice

shall be insulated with sleeving (item 17).

3. Connect 2 leads (item 15) to each winding extension Tl, T2and T3usings!Jhce

(,tem 16). Splices shall heinsulated with sleeving (item 17). Solder leads (item 15)

to diodes (items 9 & 10) as shown in connection diagram.

4. All splices (item 16) shall be ,nstalled in accordance with MIL-STD-454, Re-

quirement 19.

5. Leads and end turns shall be tied on both ends with sleeving (item 32) at approxi-

mately every other slot.

6. Exciter rotor assembly shall be within .5 oz-inch of static balance. ff required,

add balance we]ghts (item 23) in slots. See slot detail for balancing.

7, Varmsb and bake in accordance with flawing No. 72-5243-1 (item 24). Outside

diameter of laminations, shaft hole, and surfaces under insulators (item 3) shall

be free of varnish. Varnish on outside diameter of laminations shall be free of

protruding mr bubbles and other surface irregularities which may.cause inter-

ference with rotation.

Figure 8-4. Exciter Rotor Assembly Winding Data

8-9/(8-10 blank)