T M 5 - 6 1 1 5 - 5 8 4 - 34

NAVFAC P-8-622-34

T O - 3 5 C 2 - 3 - 4 5 6 -2

TM-0568C-34

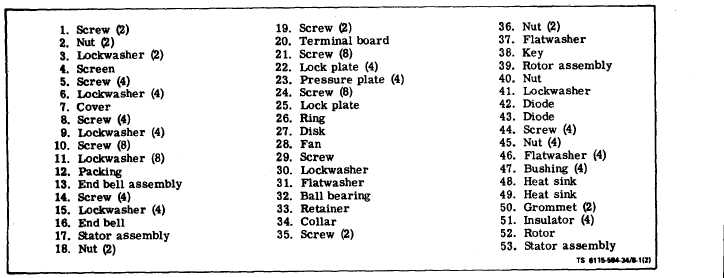

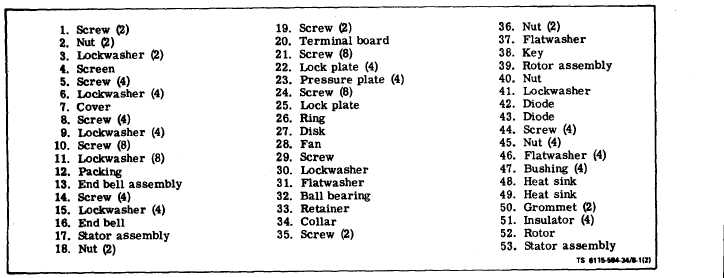

Figure 8-1. Generator Exploded View (Sheet 2 of 2)

c. Disassembly (see figure 8-l).

(1) Remove screws (l), nut (2), lockwasher (3),

attaching screen (4) to generator and remove screen.

(2) Remove screws (5), lockwashers (8), attaching

end bell cover (7) to end bell and remove cover.

(3) Remove screws (8) and lockwashers (9) hold-

ing bearing retainer (33) to the end bell (16). Remove

screws (10) and Iockwashers (11) attaching end bell

assembly (16) to stator assembly and remove end bell

assembly.

(4) Remove "O" ring (12) from bearing housing.

Remove and tag wiring harness from terminal board

(20). Remove screws (19) and nuts (18) attaching ter-

mtnal board to exciter stator and remove terminal

board.

(5) Remove four screws (14) and lockwasher (15)

attaching exciter stator (17) to end bell (16) and re-

move exciter stator.

(6) Remove eight screws (24) attaching coupling

disk (37) to rotor shaft and remove coupling, lock

plate (25) and retaining ring (26).

(7) Remove generator fan (28) which is now free.

Do not remove balance screw from fan (28).

(8) Remove rotor assembly from stator assembly

(53).

(9) Remove screw (29), lockwasher (30) and flat-

washer (31) attaching bearing (32) to rotor shaft and

remove bearing, bearing retainer (33) and shaft collar

(34).

(10) If necessary, remove diodes from rotor as

given in paragraph 8-2a above.

D o n o t r e m o v e e x c i t e r r o t o r f r o m r o t o r

s h a f t

u n l e s s

t e s t

r e s u l t s

i n d i c a t e

n e e d f o r r e p l a c e m e n t.

d. Inspect. Visually inspect windings and lead con-

nections. Check that diodes are securely mounted on

heat sinks. Clean dust, dirt, and grease from diodes.

Clean windings and drain holes. Check that end bear-

ing is not damaged or worn. Inspect cooling fan and

coupling for damage.

e. Testing Exciter Stator (Field) (High Potential

T e s t ) .

-

Observe safety regulations. The voltages used

in this test are dangerous to human life. Con-

tact with the leads or the windings under test

may cause severe, and possibly fatal, shock.

Arrange the high voltage leads so that they are

not in a position to be accidentally touched.

Keep clear of all energized parts. Always re-

duce the test voltage to zero and ground the

winding under test before making any mechan-

ical or electrical adjustments on the equip-

ment. When grounding out windings which have

been tested, always connect the connection

wire to ground first, and then to the winding.

Never perform this test without at least one

other person assisting. Generator frame shall

be securely grounded.

(1) General. The high potential test is performed

to determine whether or not the insulation of the

equipment under test is defective. It is customary to

determine whether electrical equipment will withstand

normal voltage stresses by means of a test in which

higher voltages than normal are applied for a definite

Change 5

8-3