TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

TM-05682C-34

(20) Place pump in horizontal position with control

unit bore (36) facing up.

(21) Center the plunger sleeve (34) in the control

unit bore (36). Position plunger sleeve pin (5) so that the

flats align with the groove in the control sleeve (34) and

the electric pencil mark (dot) faces the top of the pump.

(22) Insert control unit assembly (4) into housing

(6), pressing gently until control unit seats.

Do not use force. If flange is not seated on pump

housing, rotate arm both ways with finger pres-

sure control unit in.

NOTE

Rotate the control unit lever through a 360° arc

to make certain that the control unit assembly

is correctly installed. Failure to rotate 360°

indicates that the plunger sleeve pin (5) is not

engaging the plunger sleeve slot.

(23 ) Install control unit assembly retaining plate, as

shown in figure 7-39 using two tab washers and two

screws. Torque screws to 20-25 inch-pounds and bend

locking tabs over screws.

NOTE

If control unit will not seat, pull it out and re-

peat steps (20 ) through (22).

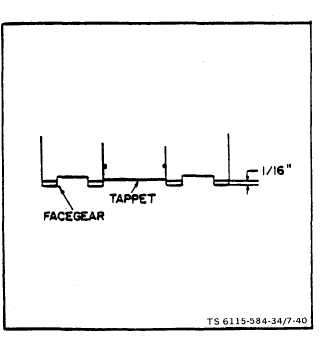

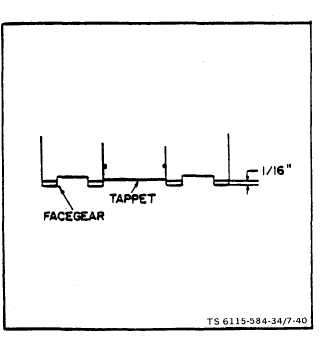

Figure 7-40. Checking Plunger Sleeve Alignment

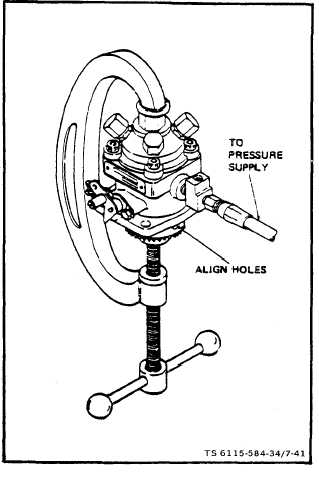

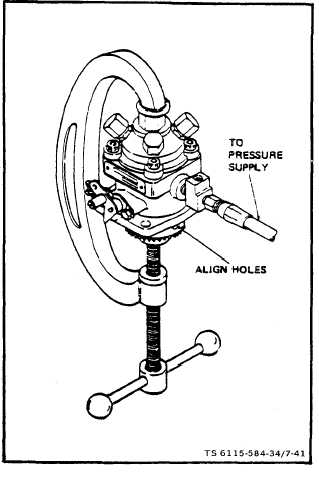

Figure 7-41. Pressure Testing Injection Pump

e. Test.

(1) Turn pump upside down and depress tappet

with thumb. Tappet should recede 1/16” into face gear

(figure 7-40). If tappet cannot be depressed 1/16” into

face gear, plunger sleeve pin (5, figure 7 -34) is improperly

aligned. Disassemble pump and re-align pin.

(2) Remove the overflow valve assembly from the

fuel outlet hole in the pump housing. Install a 1/4” pipe

plug into the fuel outlet hole.

(3) Secure the pump close to a Nozzle Test Stand.

(4) Cap outlet ports (see figure 7-41).

(5) Install C-clamp on injection pumps as shown in

figure 7-41 to retain face gear.

(6) Align holes in face gear and housing (see figure

7-41).

(7) Connect the Nozzle Test Stand to the fuel inlet

hole in the pump housing.

7-37