TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

(14) Refer to paragraph 7-7 and install blower wheel.

(15) Refer to paragraph 7-9 and install cylinder

heads.

(16) Refer to Operator and Organizational Mainte-

nance Manual and install blower housing.

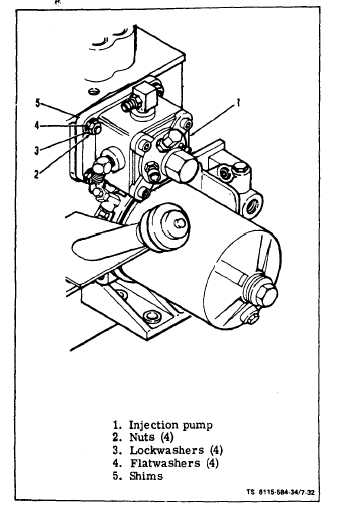

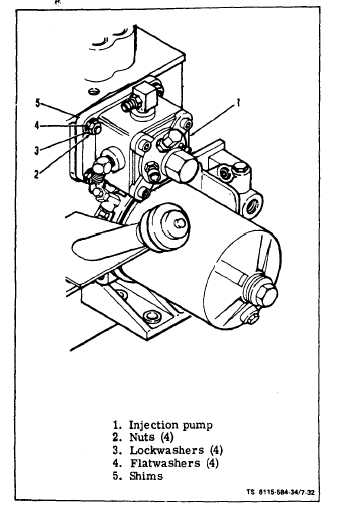

7-18. FUEL INJECTION PUMP.

a. Removal (see figure 7-32).

(1) Snap off governor linkage from injection pump

(1), and governor control arm and remove linkage.

(2) Refer to paragraph 7-2 and disconnect inlet and

fuel return lines from pump. Tag and disconnect high pres-

sure lines at injector nozzle end at injector pump.

NOTE

All fuel connections must be plugged or capped

to prevent contamination.

Figure 7-32. Injection Pump

(3) Remove four hexagon nuts (2, figure 7-32). lock-

washers (3), and flatwashers (4) holding pump (1) to

crankcase and lift pump off crankcase. Be careful to retain

the shims (5) between the crankcase and pump. The correct

thickness of shims as stamped on the crankcase is important

to proper pump operation; it provides the proper gear lash.

This thickness does not change when a new pump is

installed. It changes only when a new cylinder block is

installed. To calculate new shim thickness, measure between

camshaft and engine block pump mounting surface. Sub-

tract that measurement from 1.171 inches. This will be the

shim thickness. Refer to fig. 7-33A. Use Gage, Depth,

Micrometer NSN5210-00-542-4602 for this measurement.

(4) When removing a pump for replacement, record

the button thickness and port closing dimensions as stamped

on the side of the pump mounting flange (figure 7- 33). These

values are important in timing a new pump to the engine.

b. Disassembly (see figure 7-34). All work on injection

equipment MUST be performed in the cleanest location

possible. No filing, scraping or sawing should be dories on

the bench where repairs are made.

(1) Clean all external dirt and grease from the

pump.

The Pump Housing Must NEVER Be Clamped

in a Vise.

NOTE

A special mounting fixture (see table 2-2) must

be made to adequately secure the pump housing.

(2) Clamp the mounting fixture in a suitable vise.

(3) Install the pump into the mounting fixture, with

two 0.3125”-18 UNC-HEX head screws.

(4) Release lock tabs (2) and remove the two control

unit retaining plate screws (1) and tab washers (2, figure

7-34) and the control unit retaining plate and stop assembly

(3). Carefully pull the control unit assembly (4) with plunger

sleeve pin (5) out of the pump housing (6). Plunger sleeve pin

occasionally may have to be removed separately. Use needle

nose pliers or magnetic pencil.

(5) Remove the delivery valve cap nut (7) and gas-

ket (8).

(6) Remove the delivery valve holder (9) then lift

out the delivery valve spring ( 10), delivery valve assembly

(11) and delivery valve spacer ( 12).

7 - 3 0

Change 7