TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

TM-0568C-34

If pin is excessively loose, install a new piston and

pin assembly.

NOTE

Piston and pins are matched sets and are not

procured separately.

(3) Rings. Place each piston ring into its

cylinder bore and using a feeler gauge measure gap

dimensions. Gap is shown in Table l-2. If gap is under

0.010 inch, file as follows:

(a) Place file in vise.

(b) Grasp piston ring in both hands.

(c) Insert file into ring gap and move ring down

the entire length of file. Be sure to apply equal pres-

sure on the ring.

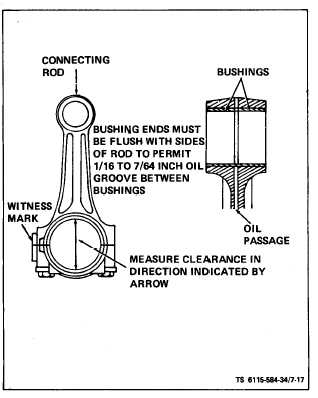

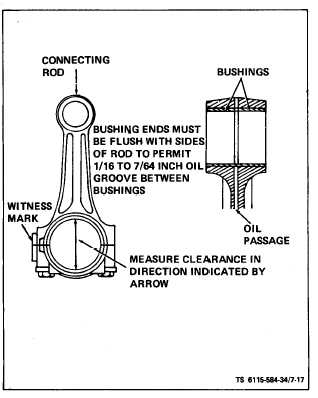

(4) Connecting Rods (see figure 7-17). Clean

connecting rods and check for each defects. Check

connecting rod bushings for proper clearance with

piston pin. Clearance is given in Table 1-2. If bushings

(13, figure 7-14) are excessively worn, press them out

and install one new bushing from each side of bushing

bore. Press new bushings only until flush with sides

of rod to leave 1/16 to 7/64 inch oil groove in center.

Ream bushing I.D. to obtain the proper clearance.

Check bore in connecting rod. Bore must be open.

Check connecting rod alignment on a standard align-

ment fixture.

Figure 7-17. Connecting Rod and Bushings

(5) Connecting Rod Bearings (see figure 7-17).

Inspect connecting rod bearings for burrs, breaks,

pits and wear. Measure clearance between bearings

and crankshaft journal. See Table 1-2 for clearance. If

necessary, repiace with new standard or undersize

precision bearings.

e. Assembly (see figure 7-14).

NOTE

The piston witness mark (notch) must face

front of engine and rod witness marks (num-

bers) must face toward camshaft side of en-

gine.

(1) Install connecting rods (12, figure 7-14) on

each piston (7) with pins (6) and retaining rings (5).

If new bushings (13) were installed, check to see that

ends are flush with the connecting rod (12) to provide

for oil recess in the center.

(2) Install rings and oil ring expander (1, 2, 3 and

4) on each piston (7). Compression rings will be

marked TOP or identified in some other manner.

Place this mark toward the closed end of piston.

Space ring gaps 1/4 of the way around piston from

one another. No gap should be in line with piston pin.

Oil the rings (1, 2 and 4) and pistons (7).

NOTE

When installing old bearings make sure they

are installed in the same position they were

removed from.

(3) Position a bearing half (11) in connecting rod

(12) and cap (10). Be sure there is no dirt under bear-

ing. This could cause high spots and early bearing

failure.

f. Install.

(1) Hone cylinder walls. Clean and oil the cylin-

der walls. Install each piston in proper cylinder using

a suitable installer. Each piston assembly should be

installed with notch on piston toward front of engine.

The notch on the circumference of the closed end of

the piston should be located closest to front of engine.

(2) Position each connecting rod on crankshaft

and oil the journal and install rod cap with bearing

half. When installing rod cap, position so raised wit-

ness mark on the forging matches the mark on con-

necting rod. See figures 7-17 and 7-18. The piston

witness mark should face front and rod witness marks

toward camshaft side of engine.

(3) Tighten capscrews to specified torque. See

table 1-1.

(4) Turn engine over by hand to see that all

bearings are free.

7 - 18