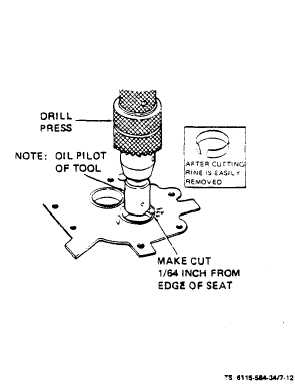

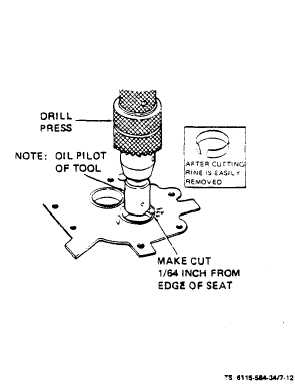

Be careful not to cut into counterbore bottom. See

figure 7-12. Thoroughly clean valve seat counterbore

and remove any burrs from the edges. Drive new valve

seat inserts into place. Be certain that each seat rests

solidly on bottom of counterbore at all points. To

make installation easier, heat cylinder head in an oven

at 325 °F (163 ºC) for about l/2-hour. Face each new

seat to the value given in table 1-2. The finished seat

face should contact approximately center of the valve

face. Use Prussian Blue on each valve face to check

this. Make any corrections on the seat, not the valve

face. When new seats are installed and faced, insert

valve into each seat and check clearance from valve

head to the face of cylinder head. If it is not the value

given in table 1-2, regrind the seat.

(4) Valve Springs. Check valve springs (5, figure

7-11) on a compression scale. Valve spring data is

given in the table 1-2. Replace any spring that is weak,

cracked or pitted or has ends out of square.

(5) Push Rods. Check that push rod is absolute-

ly straight. Replace bent or worn push rods.

e. Reassemble.

(1) Push a valve stem oil seal assembly (4) onto

each intake valve guide (6, figure 7-11). Then oil inside

surface of each seal.

(2) Oil the stem of each valve (8 and 10, figure

7-11) and insert each in its own guide (6 and 9). If in-

take valve (8) is removed with seal in place on guide,

wrap sharp edge of valve notch with cellophane tape

to protect seal bore.

(3) Check each valve for a tight seat.

(4) Using a valve spring compressor (see figure

7-10), compress each valve spring and insert the valve

spring retainer (3, figure 7-11) and retainer locks (2).

Install valve rotator (l).

f. Install (see figure 7-9).

(1) Place head assembly (8) and gasket (10) on

cylinder block (9). Install springs (18), washers (19)

and packings (16) on push rod shields (17) and install

assembled push rod shields in cylinder block. Lift

back side of cylinder head and place push rod shields

in place, lower cylinder head in place. Use an anti-seize

compound on head bolt threads and thread bolts (4

and 6) and washer (7) into cylinder block (9).

Do not tighten head bolts at this time.

(2) Refer to Operator and Organizational

Maintenance Manual and install intake manifold. Tor-

que bolts 13-15 ft-lbs (see table l-l). Bend over lock

tabs. Now tighten head bolts 44 to 46 ft-lbs (see table

1-1) following the sequence in figure 7-13.

TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

TM-05682C-34

Figure 7-12. Valve Seat Replacement

(3) Refer to Operator and Organizational

--

Maintenance Manual and install mufflers.

Install push rod with longer shouldered

end toward rocker arm. Improper installa-

tion causes push rods to bend or break.

(4) Install push rods (15, figure 7-9), rocker arms

(3), rocker arm balls (2) and rocker arm nuts (l).

(5) Set valve clearance per Operator and

Organizational Maintenance Manual.

(6) Refer to Operator and Organizational

Maintenance Manual and install air shutter assembly

and shroud assembly.

NOTE

After the first 50-hours of operation, read-

just valve clearance.

7-10. PISTON AND CONNECTING ROD.

a. General (see figure 7-14). Each piston (7) is fit-

ted with three compression rings and an oil control

ring (4). Full floating piston pins connect the piston

to the connecting rod. The pins are held in place with

retaining ring (5) at each end. The lower end of each

connecting rod contains half shell precision bearings

(11) and the upper end contains reamed bushings (13).

Change 5

7-13