e. Replace. Using screws (13, figure 7-2), lock-

washers (14), and nuts (15), attach governor control

bracket (12) to engine back plate. Attach speed control

cable (11) to governor arm (3) with pin (6) and cotter

pin (5). Attach governor arm (3) and governor linkage

(1) between governor and fuel injection pump (2). If

new ball joints are used on linkage, position the new

joints to obtain the same length or 1/32 inch more (1

turn = 1/32 inch) than the old linkage. If old linkage

length is not available, position new ball joints about

midway on each end linkage, then lengthen 1/8 inch.

Do not overspeed engine for more than a

moment.

Start engine and adjust speed control for 61.5 Hz output at no load.

It should then be possible to move the entire linkage down 1/2 inch

with a light finger pressure. If not, adjust linkage 1 turn at a time until

1/2 inch downward travel is obtained. It should then be possible to

momentarily lift the linkage 1/2 inch with unit operating at rated load.

Balance up and down travel by adjusting length of the linkage. On

ASK equipped generators, refer to Operator and Organizational

Maintenance Manual and replace right panel assembly.

7-4. FLYWHEEL AND RING GEAR ASSEMBLY.

a. Removal (see figure 7-3).

(1) Remove engine from set per paragraph 2-9.

(2) Remove timing pointer (10, figure 7-3) by re-

moving screws (11).

(3) The flywheel (1) is a tapered fit on the

crankshaft (2). Remove flywheel mounting screw (3)

and washer (4). Support and remove flywheel and ring

gear assembly by using a two pronged wheel puller

inserted through the slots provided in the flywheel.

b. Clean and Inspect. Clean the flywheel and ring

gear assembly (1) using solvent. Check the ring gear

for broken or worn teeth.

c. Install. Replacement flywheels are supplied with

timing marks already stamped in place. The engine

must still be timed properly to this timing mark. The

only accurate method of determining the port closing

point is to measure piston travel. This is a critical

measurement and should be done only with accurate,

dependable equipment. Mount flywheel keying

properly and tighten in place using screw (3) and

washer (4), (figure 7-3). With the flywheel mounted,

rotate flywheel counterclockwise until Number 1

cylinder is on its compression stroke, which follows

the closing of its intake valve. Remove the exhaust

rocker arm (3, figure 7-9), exhaust valve rotator (1,

figure 7-11), valve looks (2), spring retainer (3) and

spring (5). using fabricated tool (see figure 7-10).

Allow exhaust valve to drop down onto top of piston.

Rotate flywheel counterclockwise until piston is at

TM 5-6115-584-34

NAVFAC P-8-622-34

TO-35C2-3-456-2

TM-0568C-34

NOTE

As the piston comes up to Top Dead Center

there is very little change in the dial indicator

reading and extreme care should be used to

establish the exact Top Dead Center.

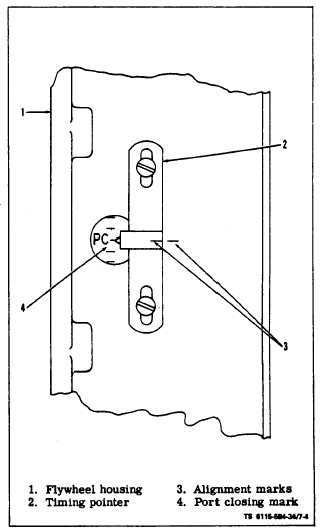

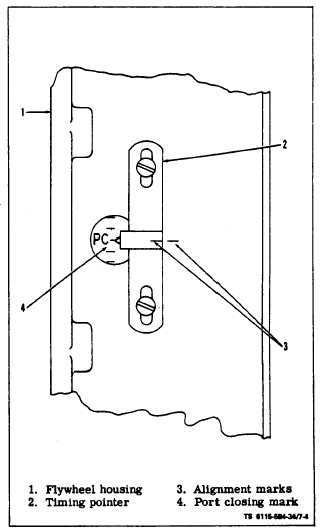

Zero the dial indicator. Rotate flywheel in opposite

direction (clockwise) to a point where the dial indica-

tor will indicate approximately 0.200 inch. Rotate fly-

wheel counterclockwise slowly until dial indicator

shows 0.128 inch before Top Dead Center. Care must

be taken to insure that the valve is following the piston,

and that reading is accurate. This procedure must be

followed to insure that all slack is taken out of the

piston and connecting rod fits. At 0.128 inch before

Top Dead Center position, check timing pointer in

timing port on side of flywheel housing (5, figure 7-3).

The timing pointer (10) should be in exact alignment

with P.C. mark on flywheel. If pointer is not in align-

ment, move pointer, and remark generator adapter

as shown in figure 7-4. Destroy old alignment mark.

Figure 7-4. Timing Port and Port Closing Mark

Top Dead Center. This can be measured on top of

exhaust valve stem with a dial indicator (see figure 7-

5).

Change 6 7 -5