TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

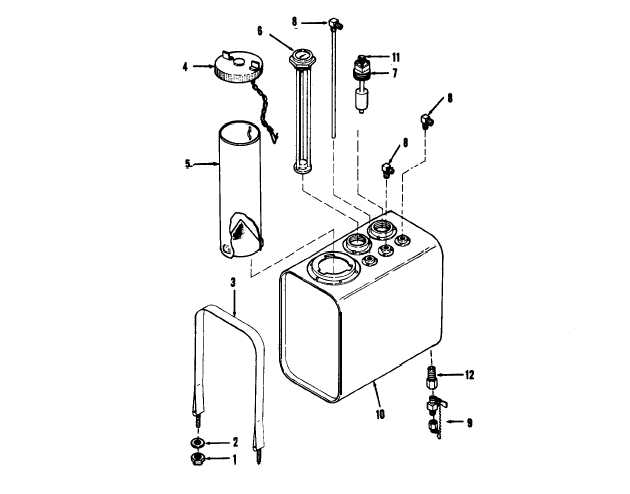

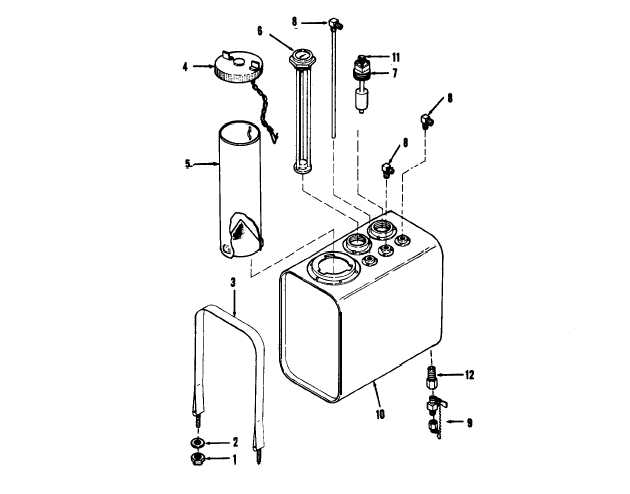

1. Nut (4)

9. Drain valve

2. Flatwasher (4)

6. Fuel gauge

10. Fuel tank

3. Srap (2)

7. Float switch

4. Filler cap

11. Connector

8. Fitting (3)

5. Strainer

18. Adapter

TS 6115-584-12/4.7

Figure 4-7. Fuel Tank Assembly

(4) Fuel Level Gauge. Engage threads of fuel

(3) Check. that drain valve is closed before filling

level gauge (5) 1/2 turn into tank (9). Coat threads

tank with proper grade of fuel.

with sealing compound MIL-S-22473. Tighten float

level gauge into tank using tools only on hex portion

NOTE

of gauge. Install filler cap (4) and strainer (5) into tank

After each time fuel filters or strainer is

(9).

drained or elements replaced, purge air from

g. Installation.

fuel system by moving master switch on con-

trol panel to PRIME & RUN position. This

(1) Install straps (3) onto the skid-base and se-

should activate the fuel transfer pump and

cure with nut (1) and flatwasher (2) on inside of skid-

force trapped air back to the vented fuel tank.

base only.

4-20. FUEL FILTER ASSEMBLIES AND STRAINER

(2) Position fuel tank assembly onto skid-base.

ASSEMBLY<

position straps over tank assembly and secure with

There are two identical fuel filter assemblies (see

nut (1) and flatwasher (2).

figure 3-13), one which acts as the primary and the

4-17