TM 5-6115-545-12

TO 35C2-3-444-1

NAVFAC P-8-626-12

TM 00038G-12

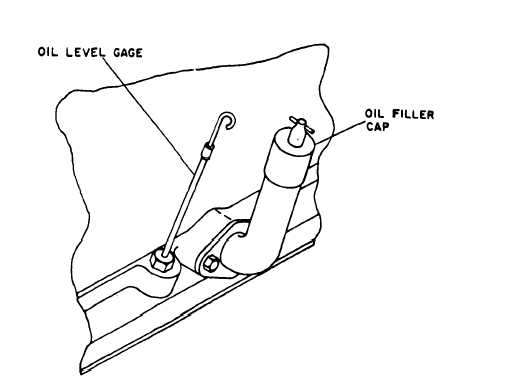

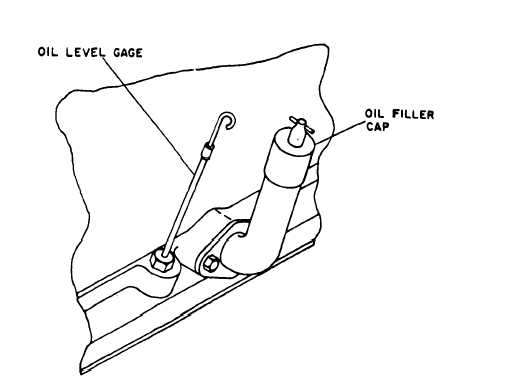

Figure 3-2.

remove breather tubes (2, 6 & 8, fig. 3-12.1) from the valve

cover, crankcase, oil separator and air intake system. Clean

inside of tubes with cleaning solvent, blow out with compressed

air, and replace on engine and oil separator.

b. Cleaning. Keep all external parts not requiring

lubrication clean of lubricants. Before lubricating equipment,

wipe all lubrication points free of dirt and grease. Clean all

lubrication points after lubrication to prevent accumulation of

foreign matter.

c. Oil Level.

CAUTION

To prevent overfill of the oil sump, remove oil filler

cap when checking oil with set running.

(1) Crankcase oil level must be checked frequently.

(2) Oil may require changing more frequently than

usual because of contamination by dilution and because sludge

formation will increase under cold weather operation conditions.

(3) Before draining the oil system, operate the engine

until a minimum coolant temperature of 160° F is obtained.

Shut engine off, open the engine oil drain valve and remove the

oil drain plug from the skid and allow the oil to drain into

appropriate container. Refer to para 3-4 d. for oil filter service.

Oil Level Gage and Filler

(4) Install the drain plug, close the oil drain valve and

fill the crankcase with 26 quarts of the specified grade of

lubricant to the FULL mark on the oil level gage. Use the side

of the oil level gage stamped STOPPED.

(5) Place dead crank switch (49, fig. 3-27) in the off

(down) position and crank engine for 15 seconds, then place

dead crank switch in on (up) position.

(6) Start and operate the engine for approximately 5

minutes.

(7) Stop the engine and allow several minutes for the oil

to drain back to the crankcase before checking the oil level.

(8) Using the oil level gage, (fig. 3-2) check the oil

level and add oil as necessary to raise the level even with the

FULL mark on the oil level gage.

(9) Observe the engine for oil leakage. Repair oil leaks

before continuing operation.

d. Oil Filter Service

See figure 3-3 and service the oil

filters as follows:

CAUTION

Disconnect negative lead from battery prior to

servicing oil falter.

(1) Drain oil filter by removing plug (l). Drain oil into

appropriate container.

3-4 Change 18