TM 5-6115-465-34

T0 35C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

8-6. WIRING HARNESS ASSEMBLIES.

not exceed 6 amperes during this test. Observe

smoothness of operation of both pump and motor.

a. Refer to the Operator and Organizational

Seal leakage of 1 cc per hour is maximum when

Maintenance Manual for wiring harness removal,

pump is operating at 2 psi discharge.

cleaning, and repair instructions.

(e) Turn power supply OFF, then re-

move motor and pump assembly from test setup.

b. If the wiring harnesses have sustained damage

f. Installation. Refer to the Operator and

and require repair or rebuild refer to figure 8-5 or

8-6 as required for layout, identification of material

Organizational Maintenance Manual for fuel burning

heater installation procedures.

requirements and Appendix A reference for detailed

soldering and replacement procedures.

8-5.

COOLANT LINES AND FITTINGS.

c. Refer to the Operator and Organizational Main-

Refer to the Operator and Organizational Main-

tenance Manual for coolant lines and fittings repair

tenance Manual for wiring harness installation proce-

dures.

instructions.

ELECTRIC WINTERIZATION KIT

Section II

8-8. TROUBLESHOOTING.

8-7.

GENERAL.

The electric winterization kit is used to maitain

which is useful in diagnosing and correcting unsatis-

the engine coolant and lubricating oil at normal opera-

ting temperature in situations which require immedi-

factory operation or failure of the electric winteriza-

ate starting of the generator set. It will function

tion kit. Each numbered malfunction is followed by an

effectively down to an ambient temperature of -65F

alphabetical listing of probable causes of the mal-

(-53. 9C). The kit consists of a heater assembly, a

function. The corresponding alphabetical listing of

heater control assembly, and interconnecting coolant

corrective actions contains references to the applic-

lines and fittings and wiring harnesses. Power for

able maintenance paragraphs for correcting the

operation of the kit may be obtained from any 208 to

cause of the malfunction

240 volt, 50/60 Hz or 400 Hz, single phase source.

NOTE

Refer to the Operator and Organizational

Maintenance Manual for troubleshooting

information applicable to lower levels of

maintenance.

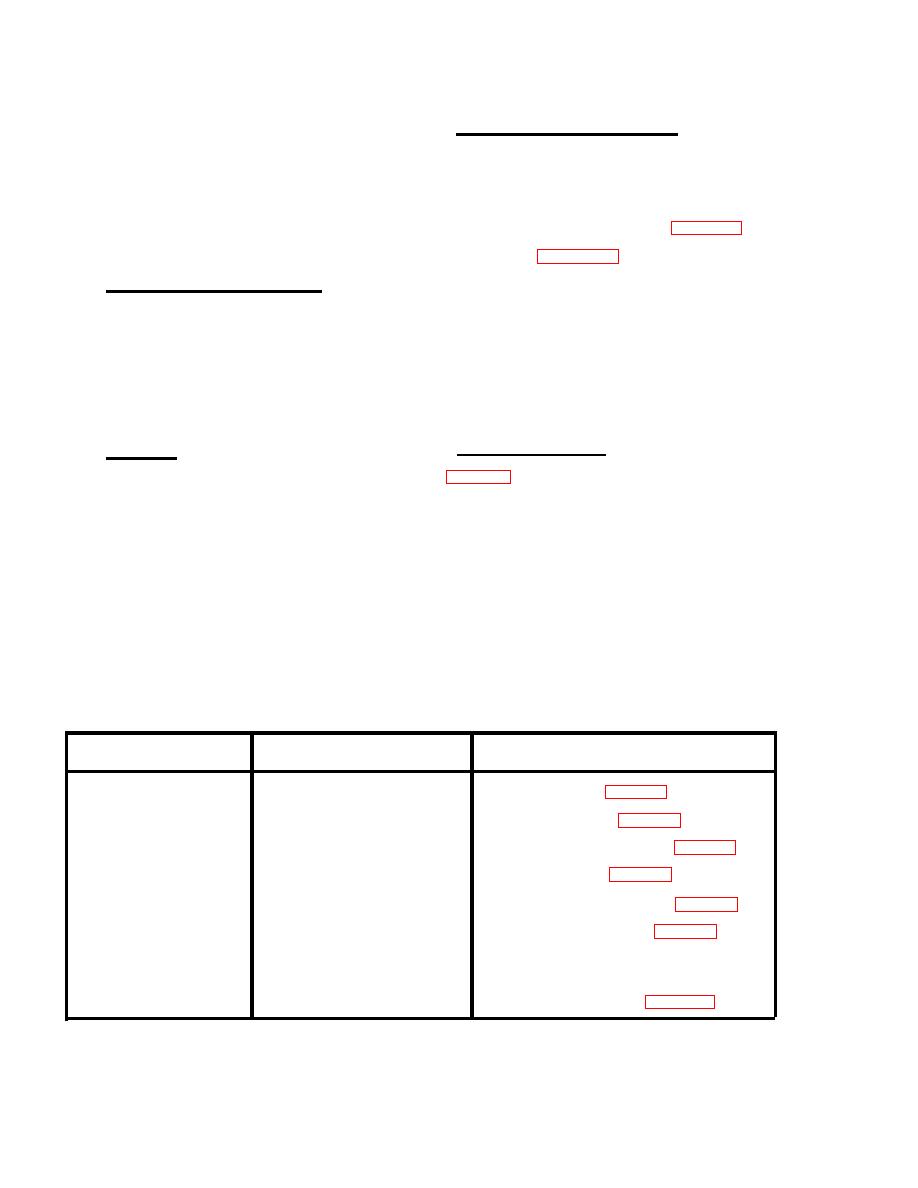

ELECTRIC WINTERIZATION KIT TROUBLESHOOTING CHART

Table 8-2.

PROBABLE CAUSE

MALFUNCTION

CORRECTIVE ACTION

a. Replace fuse (para. 8-9).

1. HEATER ON indicator

a. Defective fuse.

light does not illum-

inate with switch in

b. Defective switch.

b. Replace switch (para. 8-9).

ON position

c. Defective circuit breaker.

c. Replace circuit breaker (para. 8-9).

d. Replace lamp (para. 8-9).

d. Defective lamp.

e. Defective semi-conductor.

e. Replace semiconductors (para. 8-9).

f. Defective transformer.

f. Replace transformer (para. 8-9).

a. See Malfunction 1 of this table.

a. See Malfunction 1 of this

2. POWER ON indicator

table.

light does not illum-

inate with switch in

b. Replace thermostat (para. 8-10).

b. Defective thermostat.

ON position.

I

8-12