TM 5-6115-465-34

NAVFAC P-8-625-34

T.O. 35C2-3-446-2

TM 06858B/06859D-34

(6) Remove corrosion and defective paint.

b.

Cleaning, Inspection, and Repair.

Treat and paint in accordance with service require-

ments.

(1) Clean all parts in dry cleaning solvent

(Federal Specification P-D-680) and dry thorough-

(7) Replace all parts worn or damaged beyond

ly.

repair.

(2) Inspect supports, lifting clevises and

brackets for cracks, corrosion, breaks, defective

c. Installation.

paint, and other damage.

(1) Install lifting frame in reverse order of

(3) Inspect lifting clevises, brackets, and

removal procedures.

pins for excessive wear.

(2) Install the housing assembly doors,

(4) Check all threads for crossing, stripping,

covers, and panels, the hydraulic sump, the fuel

and other damage.

lines and fittings, the day tank assembly, and the

main fuel tank filler neck removed in steps a. (1)

(5) Repair cracks and breaks in supports by

through a. (4) above.

welding.

SKID BASE ASSEMBLY

Section III.

6-5.

GENERAL.

NOTE

The skid base assembly provides the mounting

It is not necessary to completely disassem-

points for the engine assembly, the generator as-

ble the skid base assembly to replace a

sembly, and the enclosure assembly. It contains the

single part. Only those parts requiring re-

main fuel tank and the tool box. The generator set

pair or replacement need be removed.

ground point is also contained in the skid base as-

sembly. The skid base is also drilled to accept

c.

Cleaning, Inspection, and Repair.

attachment of the wheel mounting kit. A metal sheet

near the bottom of the skid base prevents the entry

(1) Clean all parts with dry cleaning solvent

of debris. Drain holes are provided to prevent the

(Federal Specification P-D-680) and dry thoroughly.

accumulation of spilled liquids on the sheet.

If necessary, use a stiff bristle brush to remove

caked deposits.

6-6.

SKID BASE ASSEMBLY MAINTENANCE.

(2) Visually inspect skid base for cracks,

Removal.

corrosion, defective paint and defective welds.

a.

(3) Inspect tool box for cracks, corrosion,

(1) Refer to the Operator and Organizational

damaged latch and hinge, and defective paint. Replace

Maintenance Manual and remove the housing assem-

bly.

tool box if damaged beyond repair.

(2) Remove the relay table assembly (para-

(4) Inspect ground terminal stud for burns,

graph 6-2).

corrosion, damaged threads or other damage. Re-

place if defects are noted.

(3) Remove engine assembly (paragraph 2-6).

(5) Repair cracks and defective welds in skid

(4) Remove generator assembly (paragraph

base by welding. File repairs to provide a smooth

2-7).

finish.

(5) Remove main fuel tank (paragraph 3- 15).

(6) Remove corrosion and defective paint.

Treat and repaint in accordance with service require-

(6) Remove the lifting frame (paragraph 6-4).

ments.

NOTE

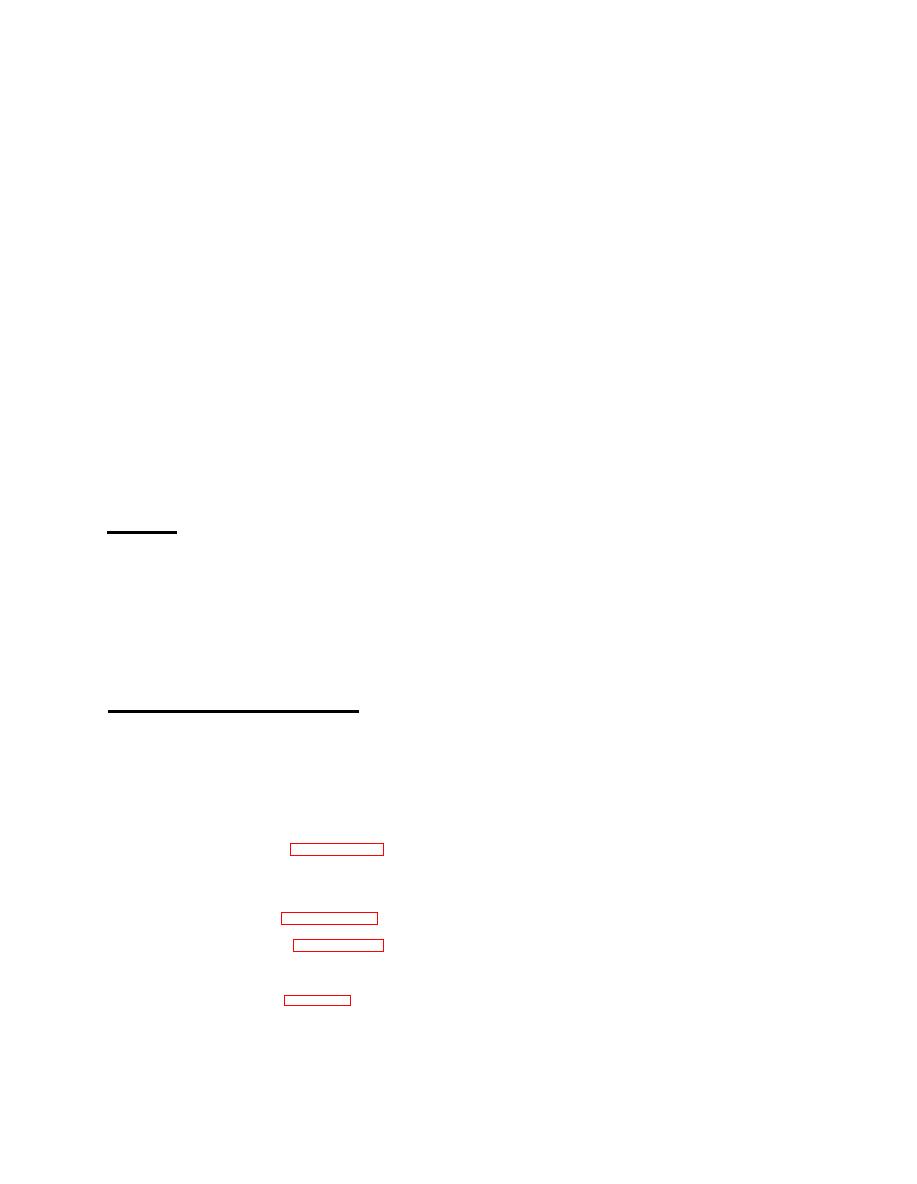

b. Disassembly, Disassemble skid base as-

sembly by following the ascending sequence of index

Clean paint from ground terminal stud

numbers (1 through 12) assigned to figure 6-3.

mounting to provide effective ground.

6-4