T.O. 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-07464A-35

tool, wiggle the tool slightly so that rack

NOTE

slides inside of collar on the rack setting

tool .

Under no condition should the

engine be run unless the control

4. Tighten two screws holding rack

shaft can move the fuel injection

setting tool until they are tight. Use a

pump rack in both directions at

the point.

wrench to tighten these two screws only

enough to firmly anchor the tool against the

Under no condition should the con-

flange face.

trol lever (39, figure 8-34) or the

5. Turn micrometer dial clockwise

rack extension be filed to make an

until the leading edge of the rotating dial

easier fit. If the parts do not

mate, it is only because the parts

lines up with NO. 1. on the non-rotating

shaft and #0 on the rotating dial. Refer to

are damaged and should therefore

be replaced, or the parts have

been assembled incorrectly,

6. Rotate shaft (33, figure 8-34)

clockwise, pushing fuel injection pump

7. If fuel rack stop assembly (1, 2,

rack forward until it contacts rack setting

3, 4, and 5) has been removed, assemble

tool; and hold in this position with right

to rear of housing but do not install cap (l).

hand,

Fuel stop will have to be set. This is

covered under governor drive housing

adjustment.

7. With the rack setting tool, set in

position as described in step 5. , slowly

b. GOVERNOR DRIVE HOUSING

rotate rack stop screw (5) clockwise with the

ADJUSTMENT. Maximum fuel stop setting

fingers or a small flat bladed screw driver

must be checked whenever governor drive

until contact is felt. While holding rack

housing is removed. Proceed as follows:

stop screw, remove right hand from shaft

(33, figure 8-34) and tighten lock nut (2)

1. Using an approved rack setting

without moving rack stop screw (5).

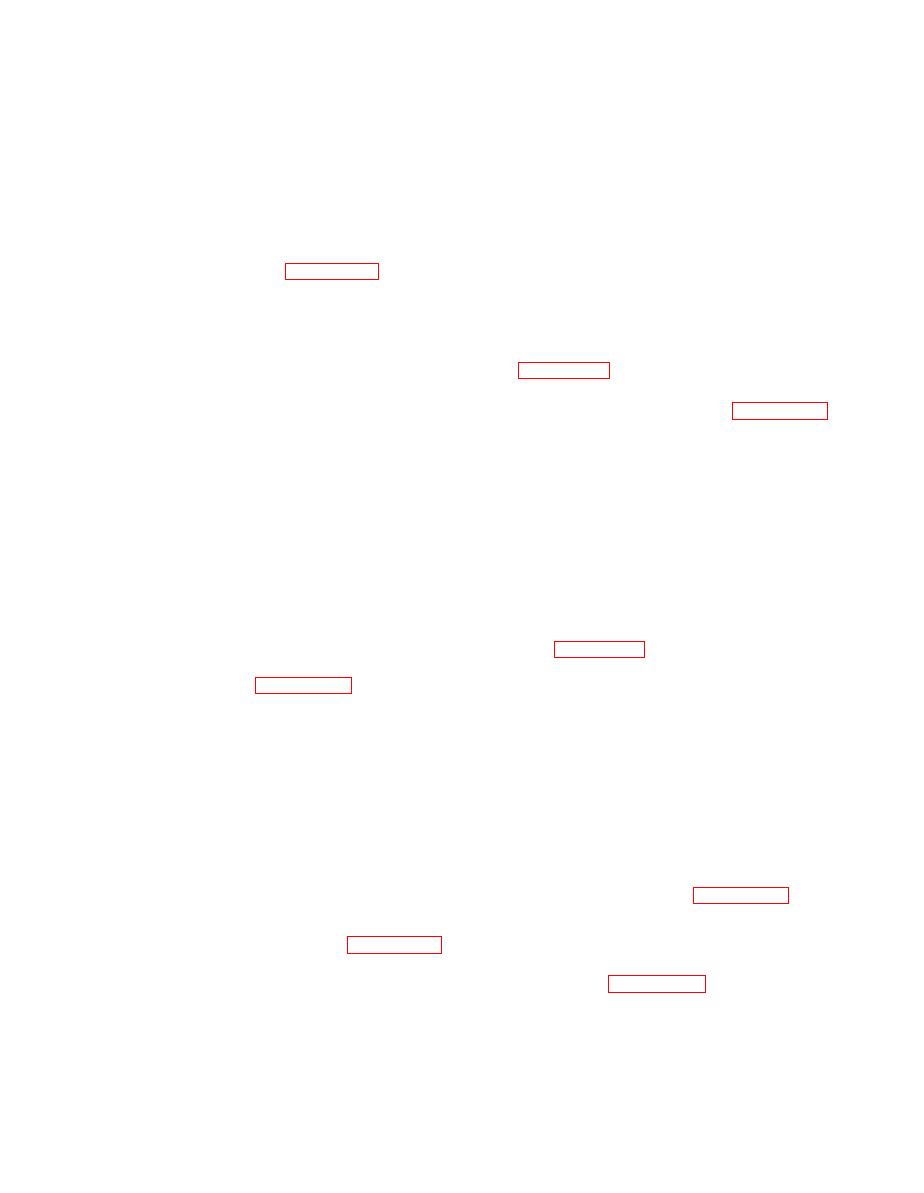

gauge, refer to figure 8-36, view B, and

remove two screws, flange, and gasket

8. To check adjustment, turn the

from flange at rear of accessory drive

rack setting tool micrometer dial a few

housing.

turns counterclockwise. Rotate shaft (33)

back and forth a few times and end up

2. Rotate knob of rack setting tool

rotating shaft (33) clockwise and hold in

counter clockwise until the number 3

full fuel position. Rotate micrometer dial

appears under the micrometer dial.

on rack setting tool clockwise until it con-

Install tool in opening, using the same

tacts fuel injection pump rack. Dial should

screws that secure the flange. Do not use

be reading +1 on the shaft and "0" on the

gasket or lockwasher. Tighten screws

rotating dial. Refer to figure 8-37 (view A)

with fingers just enough to engage threads.

for allowable tolerances.

3. Rotate shaft (33, figure 8-34)

in a clockwise direction, pushing the pump

9. If reading is not within indicated

rack toward the front of the unit. When end

tolerances (figure 8-37, view A), repeat

of rack contacts open end of rack setting

procedure starting with step 5.

8-83