P-9-TM-457-35 T.O. 35C2-3-442-2

TM-07464A-35 TM 5-6115-457-34

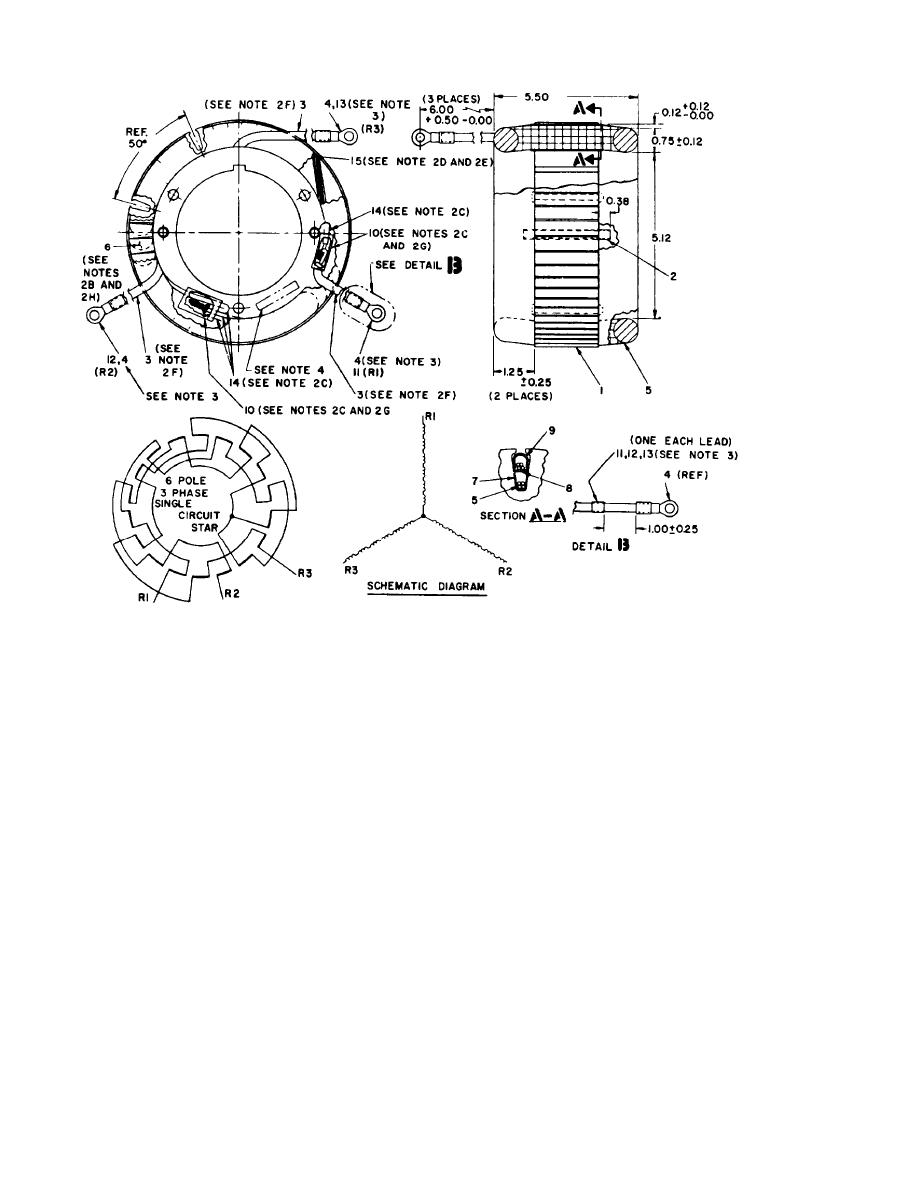

NOTES:

1. COIL DATA:

A. WIRE SIZE: 0.040 DIA (#18 GA), CLASS 155, TYPE L2.

B. NUMBER OF WIRES PER TURN: 6

c. NUMBER OF TURNS PER COIL: 3

D. NUMBER OF WIRES PER COIL: 18

E. COIL GROUPING: 18 GROUPS OF 2 COILS

F. COIL SPAN: SPAN 1 AND 6.

2. ROTOR WINDING PROCEDURE :

A. WIND COILS TO PROPER SHAPE, SPECIFIED DIMENSIONS AND NUMBER OF TURNS.

B. HOLD COILS TOGETHER WITH TAPE, INDEX 6.

C. APPLY INSULATION SLEEVING. INDEX 14 AND 10 (LOOSE}.

D. SELECT AN ARBITRARY SLOT ON CORE, INDEX 1, AND INSERT FIRST COIL GROUP WITH

START LEAD IN THE BOTTOM OF SLOT NO. 1 AND `hi E ENDING LEAD IN THE TOP OF SLOT

NO. 6 (COIL SPAN 1 AND 6).

E. INSERT THE NEXT COIL GROUP PER GROUPING SEQUENCE. INSERT PHASE INSULATION,

INDEX 15, DURING PLACING OF COILS. REPEAT SEQUENCE UNTIL WINDING IS COMPLETE.

F. MAKE PHASE CONNECTION AND CONNECT LEADS, INDEX 3, PER CONNECTION DIAGRAM,

(HOMOGENEOUS WELD).

APPLY SLEEVING, INDEX 10, OVER LEADS, INDEX 3, CONNECTIONS AND PHASE CONNECTION.

H. WRAP WINDING WITH TAPE, INDEX 6.

J. VARNISH. REFER TO FIGURE 7-5 NOTE 4.

3. CUT LEADS, INDEX 3, AND INSTALL TERMINALS, INDEX 4, AND WIRE MARKERS, INDEX 11, 12,

AND 13, TO DIMENSIONS SHOWN. CRIMPING OF TERMINALS TO MEET THE REQUIREMENTS AND

TESTS OF MIL-T-7928. HEAT WIRE MARKERS, INDEX 11, 12, AND 13, TO 200' F FOR 5 SECONDS.

STAMP PART NUMBER AS SHOWN BELOW PER MIL-STD-130, 0.12 MIN HEIGHT, USING WHITE

4.

ENAMEL PAINT

30554 ASSY 70-4519

MFG (MFG CODE)

5. AFTER REWINDING, PERFORM INSPECTION SPECIFIED IN PARAGRAPH 7-5, STEPS M AND Q,

7-20