P-9-TM-457-35 T.O. 35C2-3-442-2

TM-07464A-35 TM 5-6115-457-34

4-22. INSPECTION.

a. Inspect threads for damage and parts

for cracks.

b. Inspect shaft for nicks, burrs, and

scoring in flange bushing area.

c. Inspect flange bushing for nicks,

scores, and out of roundness.

d. Inspect springs for distortion and

broken ends.

e. Test power element for proper

operation, refer to Operator and Organiza-

tional Maintenance Manual.

f. Inspect manual control handle for

distortion.

4-23. REPAIR.

a. Remove nicks and burrs using a file

or stone.

b. Straighten distorted manual control

handle using suitable tools.

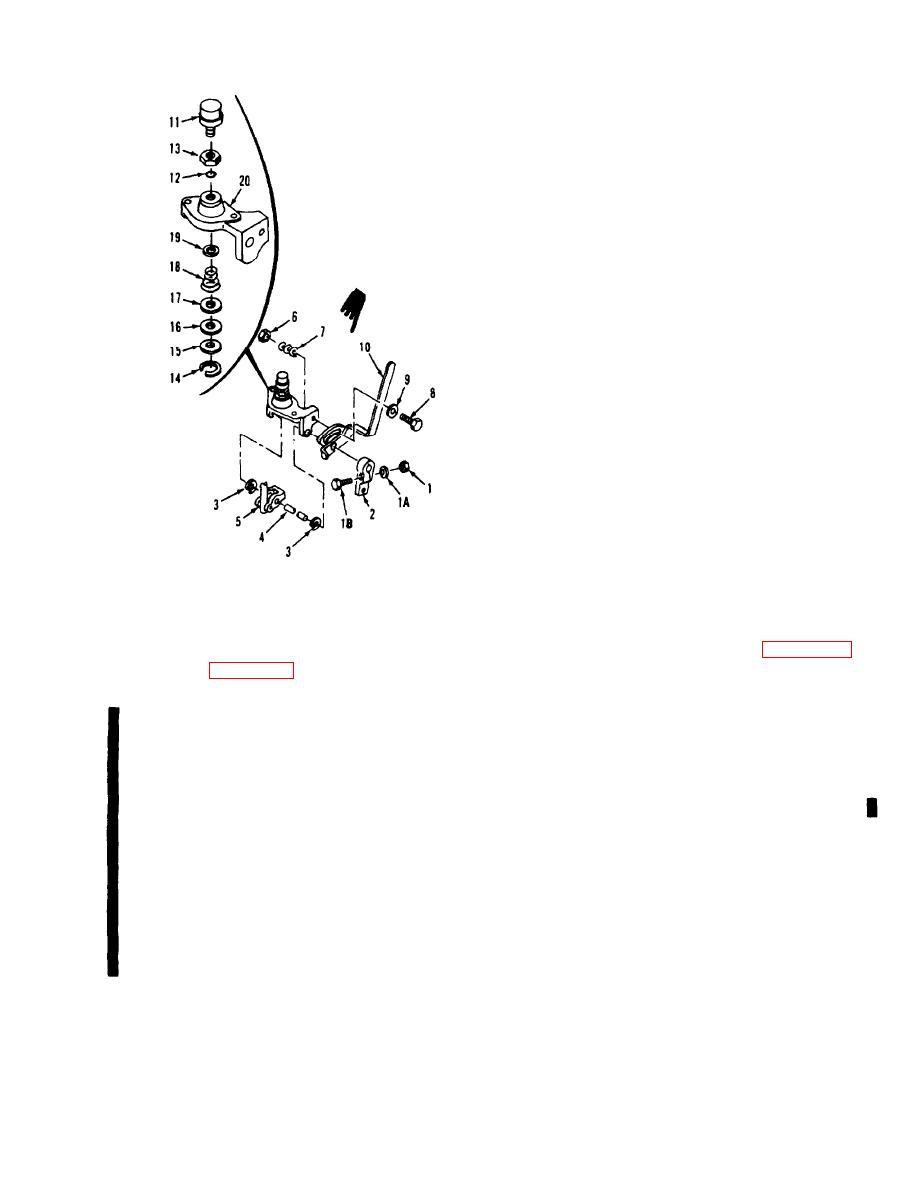

Figure 4-2. Shutter control

exploded view

4-24. REASSEMBLY. Refer to figure 4-2

and reassemble the control assembly in the

Legend to figure 4-2:

reverse order of index numbers assigned.

Pay particular attention to the following:

Power

11.

1.

Nut

1A.

Lock washer

element

a. Apply a thin film of oil to packing

1B.

Screw

12.

Preformed

(12), Position nut (13) and packing (12) on

2.

Lever

packing

power element (11). Screw power element

3.

Retainer

13,

Nut

into housing (20) until top of power element

4.

Shaft

14.

Retaining ring

is 2.75 inches above flat or flange. Hold

5.

Yoke assembly

15.

Large seat

power element stationary and tighten nut (13).

6.

Nut

16.

Felt washer

7.

Friction spring

17.

Large seat

b. Tighten nut (6) tight enough to apply

Screw

8.

18.

Spring

spring tension on manual control handle (10)

Washer

9.

19.

Small seat

and still permit movement of handle.

10.

Manual control

20.

Shutter power

handle

element

housing

4-5

Change 1