TM 5-6115-400-35

(5) Turbine and Compressor Housings.

(1) Center Housing Assembly. The center

housing assembly must show no signs of

Make certain that the turbine and

contact with rotating parts. Oil passages

compressor housings are clean and have

must be clean and free of obstructions.

no internal obstructions that could impede

Inspect bearing bores for scored surfaces

the flow of gases.

and excessive wear. Using a micrometer

(6) Rotating Assembly. Every rotating part is

and a telescoping gage, measure bearing

balanced individually and can be

bore diameter. The bearing bore of the

replaced, without displacing overall

center housing must not be out of round

balance of the assembly.

or exceed .9835 inch I.D. Using a straight

(a) Compressor Impeller. Inspect the

edge and a feeler gage, check turbine

blades and bore of the compressor

shroud for distortion. Distortion must not

impeller.

Check impeller blade

exceed .005 inch.

edges and the underside of the

impeller wheel for indications of

Note.

wear. Wear occurs at these points

The shroud is not a serviceable part

as

a

result

of

excessive

If replacement is necessary, a center

bearing/thrust collar wear. Check

housing assembly, which includes

impeller surfaces for excessive and

the shroud, must be installed.

unevenly

distributed

dirt

accumulations.

Such

(2) Impeller Shaft Bearings.

Replace

accumulations disturb the precision

bearings if they show signs of scoring,

balance of the rotating assembly.

nicks, shellac deposits, or foreign material

Check to ensure that the impeller

imbedded in the metal.

wheel bore is not scratched or

scored.

Measure bearing O.D. and I.D. with a

micrometer. The dimensions of bearings

are O.D., not less than .9785 inch, I.D.

not more than .6272 inch.

(3) Thrust Bearing. The grooved side of the

thrust bearing must not be scored or have

any foreign material imbedded in its

surface. Use a micrometer and measure

overall thickness of the thrust bearing at

three points, 1200 apart.

The

measurements obtained must not be less

than .089 inch or vary more than .001

inch from one reading to the other.

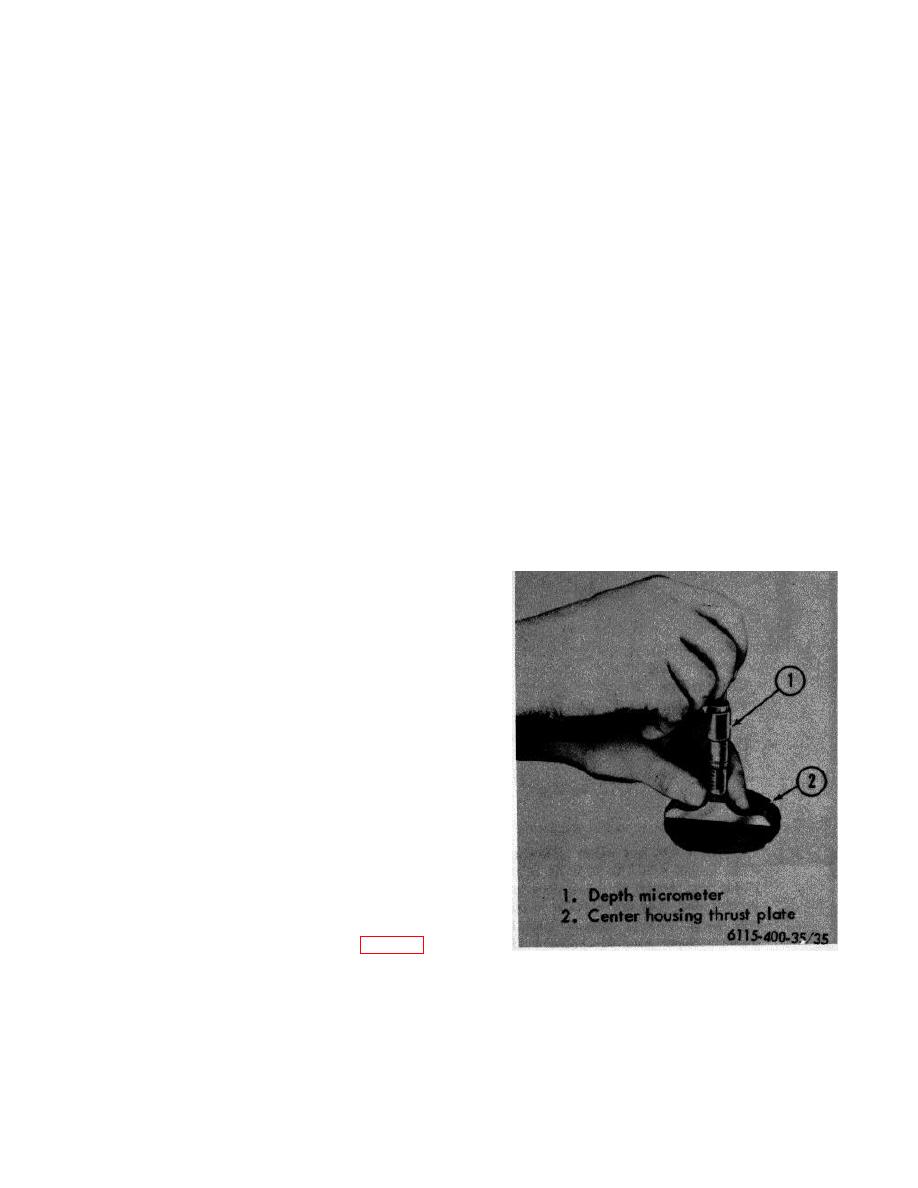

(4) Center Housing Thrust Plate. Passages

in the thrust plate assembly must be clean

and free of obstructions.

Blow out

passages with compressed air. The bore

for the sealing ring must not be scored or

rough. The thrust plate bearing surface

must not be scratched or scored. With a

depth micrometer, measure the distance

between the bearing surface and the

opposite surface of the thrust plate at

three points, 1200 apart (fig.

Figure 35. Checking center housing thrust plate

Readings obtained must not exceed .399

bearing surface for wear.

inch not vary more than .001 inch

between measurements.

70