TM 5-6115-400-35

Caution.

If the thrust spacer moves out of

position in the thrust plate and

causes misalignment of the seal ring,

repeat this step.

(10) Check hole alignment. Install lock plates

and capscrews. Tighten capscrews to 30

to 40 in. lb. torque. Bend lock plate tabs

to secure capscrews (fig. 37F).

(11) Heat compressor impeller in a furnace,

oven, or hot oil bath at 350 for 10

F

minutes maximum.

Heated impeller

wheel will readily slip onto shaft. Install

heated impeller on shaft.

Caution.

Use asbestos gloves when handling

the hot impeller. If the compressor

impeller was not heated sufficiently

or if it cooled too rapidly, the

impeller may shrink on the shaft

before it contacts the thrust spacer.

Do not apply force.

Refer to

paragraph d, steps (7) and (8) for

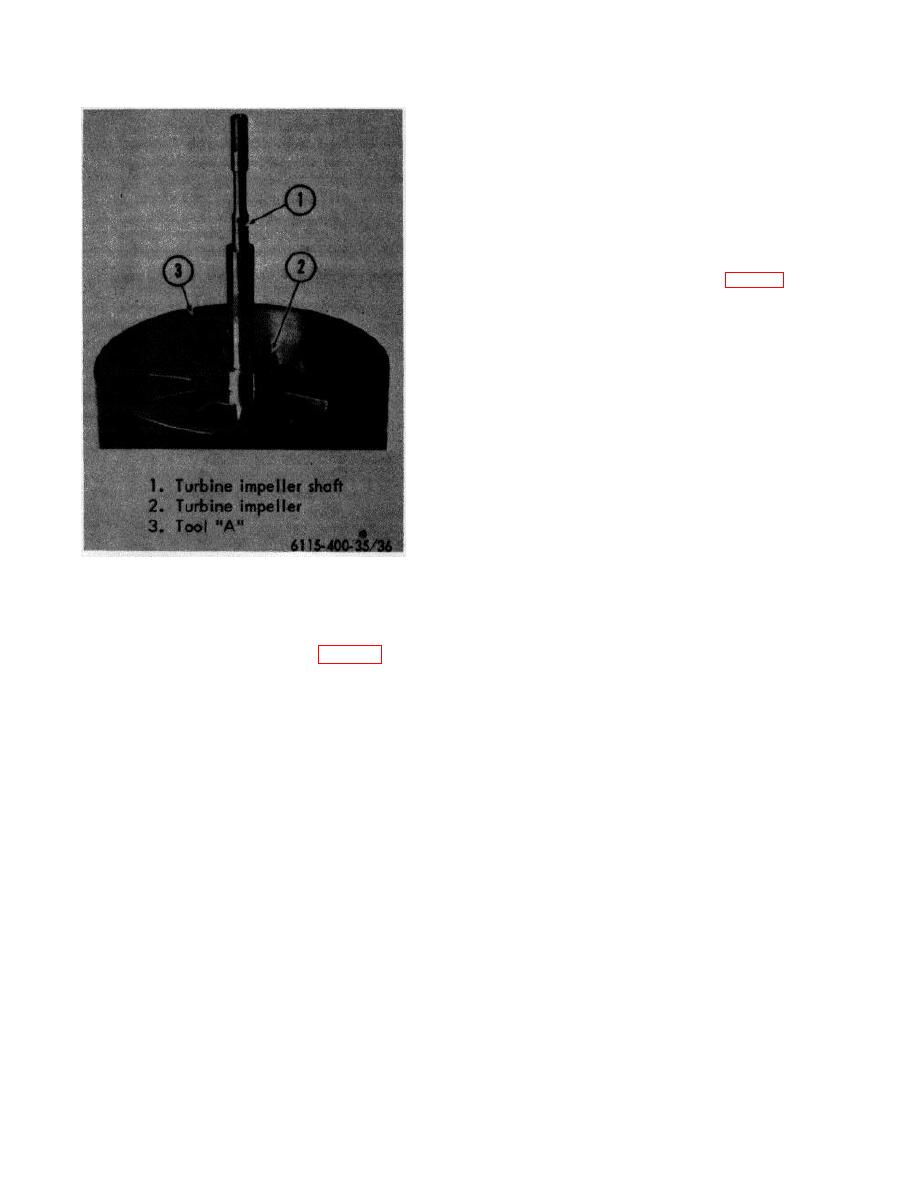

Figure 36. Turbine and shaft positioned in holding

proper' impeller removal procedure.

fixture

(5) Lubricate bearing for compressor end of

(a) Bottom or seat compressor impeller

assembly. Carefully guide impeller shaft

by installing impeller locknut.

bearing onto the shaft and into bore of the

Tighten to 150 to 160 in. lb. torque.

center housing assembly (fig. 37A).

(b) Allow impeller to cool to 150 or

F

(6) Install thrust bearing with hole and cutout

less and remove locknut. Inspect

in bearing aligned with center housing

washer contact face of nut and hub

dowel pins. Bearing must be flat against

of wheel. Both surfaces must be

the housing (fig. 37B).

smooth and clean.

Lubricate

(7) Install thrust ring on shaft, dished side up

threads and contact face of nut.

(fig. 37C).

(c) Reinstall the locknut. Position Tool

(8) Install sealing ring on thrust spacer.

H on the locknut. Mount a magnetic

base or clamp type dial indicator on

Carefully insert thrust spacer and sealing

the center housing with the indicator

ring into the center housing thrust plate.

contact point reseating on flat end

(9) Install lubricated preformed packing on

surface of shaft (fig. 37H). Set dial

center housing thrust plate. Align thrust

indicator to ZERO. Insert sliding T-

plate oil hole with matching hole in the

handle into upper end of Tool H.

center housing. Insert thrust plate into

Tighten locknut until shaft length

center housing using care to avoid

increases .006 inch to .007 inch.

disturbing position of the thrust spacer

(fig. 37E).

72