TM 5-6115-400-35

(9) If the turbocharger meets the above

inspection specifications, it can be

reassembled and considered satisfactory

for further service.

(10) Install turbocharger on the engine. Refer

to TM 5-6115-400-12.

Note.

If undue impeller shaft bearing wear

or other damage is believed to have

been caused by lack of lubrication,

check the flow of oil to the

turbocharger

with

the

engine

running. Minimum oil pressure at

the turbocharger is 10 psi when oil

temperature is 180F.

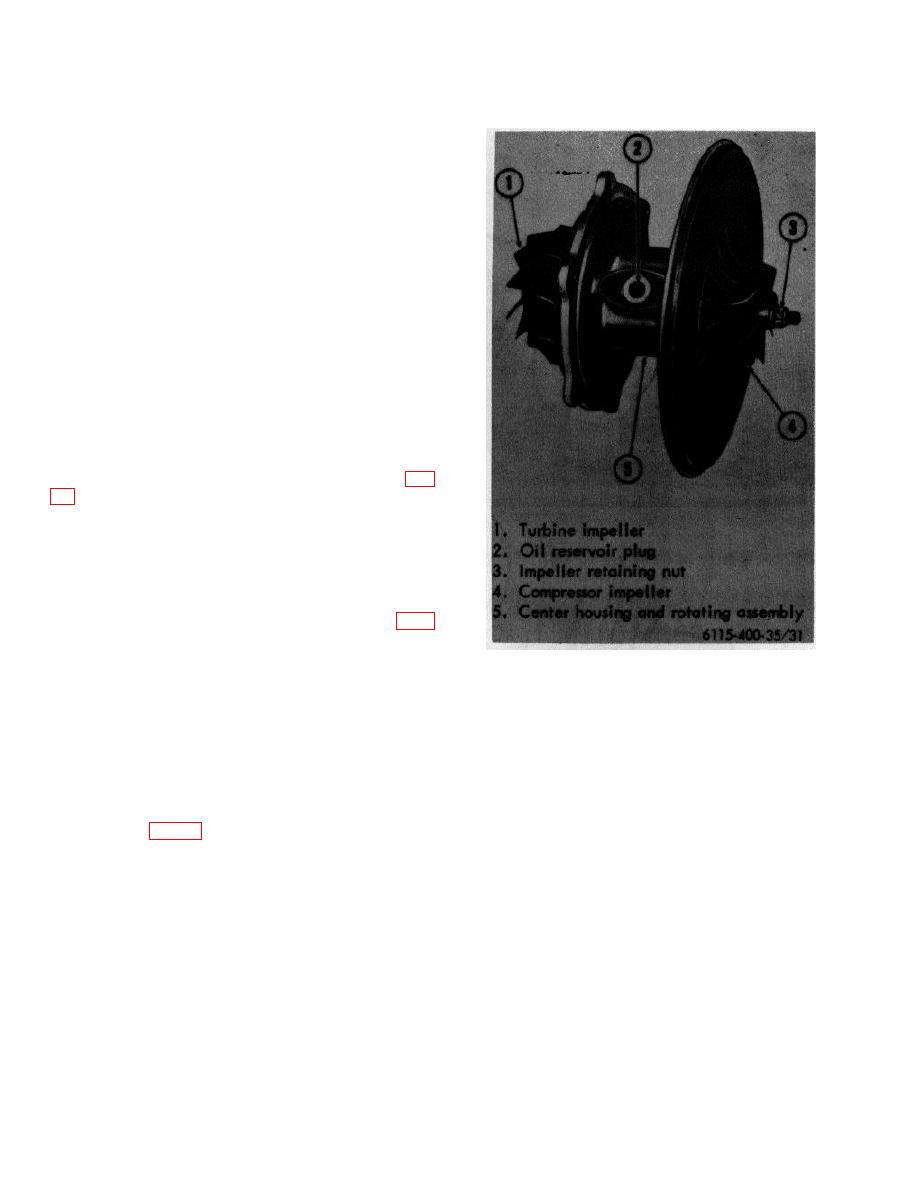

c. Replacement Center Housing and Rotating

Assembly.

When complete disassembly of the

turbocharger is not feasible, a replacement center

housing and rotating parts assembly may be used (fig.

transfer the used turbine and compressor housings to

the new center housings and rotating parts assembly.

Follow the disassembly procedure outlined in paragraph

d. Assemble by following the instructions in paragraph f.

d. Disassembly of Turbocharger. Disassembly of

the Model T-1818 turbocharger can best be

accomplished with the use of service tools listed in table

2. Clean the exterior with a non-caustic cleaning

solvent. As parts are removed they should be placed in

Figure 31. Center housing and rotating assembly

protective containers on a clean bench in the order of

(4) Straighten tabs of lockplates and remove

disassembly. Always handle the parts with care to

capscrews and lock plates securing

prevent scratching the precision machined surfaces.

turbine housing to center housing. If

Check turbine wheel shaft radial movement with a dial

necessary, tap turbine housing with a soft

indicator and record the measurement obtained as this

hammer and remove from center housing.

will be required later to determine amount of bearing

(5) Record compressor and turbine shaft

bore wear in the bearing housing.

radial movement and the shaft end play.

(1) Mark relative positions of compressor and

Follow procedure as outlined in paragraph

turbine housings to the center housing

b.

(fig. 33A).

(6) Clamp holding fixture (tool A) in vise.

(2) Apply penetrating oil or diesel fuel to

Mount center housing and rotating

capscrews securing turbine housing to

assembly in holding fixture with turbine

center housing.

impeller downward Make certain the

(3) Remove capscrews, lockwashers, and

hexagon countersunk hole in turbine

clamps securing compressor housing to

impeller goes over hexagon protrusion of

center housing.

If necessary, tap

holding fixture to prevent the shaft from

compressor housing with a soft hammer

turning.

and remove from center housing.

65