TM 5-6115-400-35

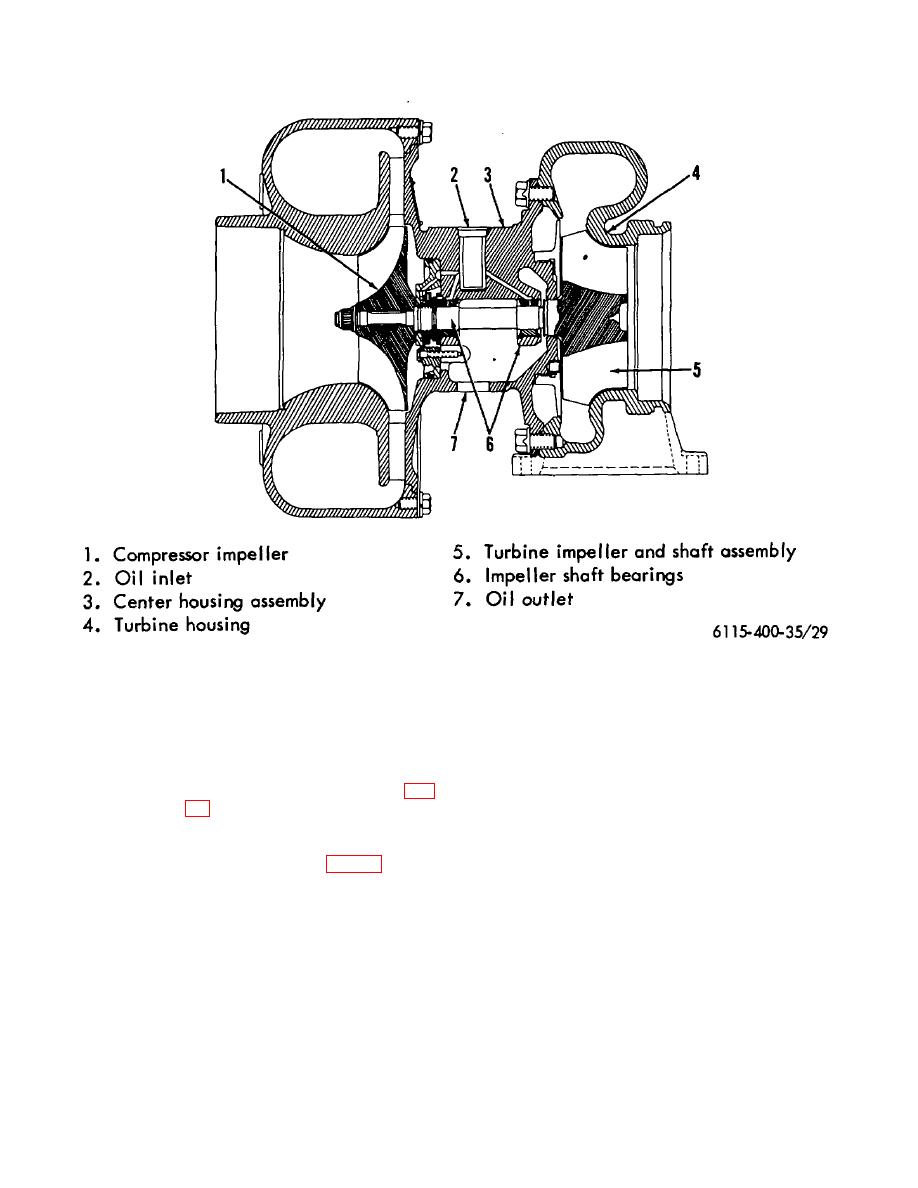

Figure 29. Turbocharger - sectional view.

(3) Remove the compressor and turbine

Note.

housings. (Refer to para. d).

For accurate indication, dial indicator

(4) Check turbine shaft radial movement as

stem end must be on same center

follows:

line as plunger of the dial indicator

adapter.

(a) Clamp

the

center

housing

compressor flange in a vise (fig.

(e) Push rotating assembly toward

indicator contact point and record

the amount of movement.

(b) Using two 3/8 inch X 1 1/8 inch

capscrews, attach dial indicator

(f) Pull the rotating assembly away

adapter, Tool F, (2, fig. 30) to the

from indicator contact point and

center housing oil drain with plunger

again record the amount of

of Tool F, resting on the impeller

movement.

shaft.

(g) The difference between the two'

(c) Attach a magnetic or clamp type

measurements is the total impeller

dial indicator to the dial indicator

movement and should be .005 inch

adapter base.

to .008 inch. Repeat this procedure

several times before accepting a

(d) Position contact point of dial

final reading.

indicator on plunge of the adapter.

63