TM 5-6115-400-35

g. Installation. Refer to TM 5-6115-400-12.

(4) Adjust operating lever high idle speed

screw until the desired full fuel quantity for

full load, as specified in paragraph 34h, is

36. Water Pump

obtained.

Adjust screw upward for

a. General.

A centrifugal-type water pump

increased delivery and downward for

assembly is provided for circulating coolant through the

reduced delivery.

engine and radiator. The pump shaft is supported in the

Note.

When a governor is

pump bearing sleeve by a ball bearing on pulley end

adjusted, there must be no rapid

and a roller bearing on rear end of the bearing sleeve.

oscillations of the fulcrum lever (41).

The bearings are splash-lubricated by oil thrown from

the engine gear train that enters through two openings in

When

this

occurs,

cause

of

the pump bearing sleeve. Lip-type oil seals at each end

fluctuations must be found and

of the bearing sleeve prevent oil from leaking to the

corrected before proceeding further.

outside and from entering the impeller compartment of

(5) If step 4 has been correctly established,

the pump body. A spring-loaded coolant seal prevents

then a slight increase in test stand rpm

coolant from seeping out of the impeller compartment.

will start control rack moving toward the

The tapered hub of the impeller is "pinned" to the rear of

stop position, thus reducing the fuel

the pump shaft and is secured by a slotted nut and

delivery.

cotter pin.

(6) Again operate test stand at governed full

b. Removal. Refer to TM 5-6115-400-12.

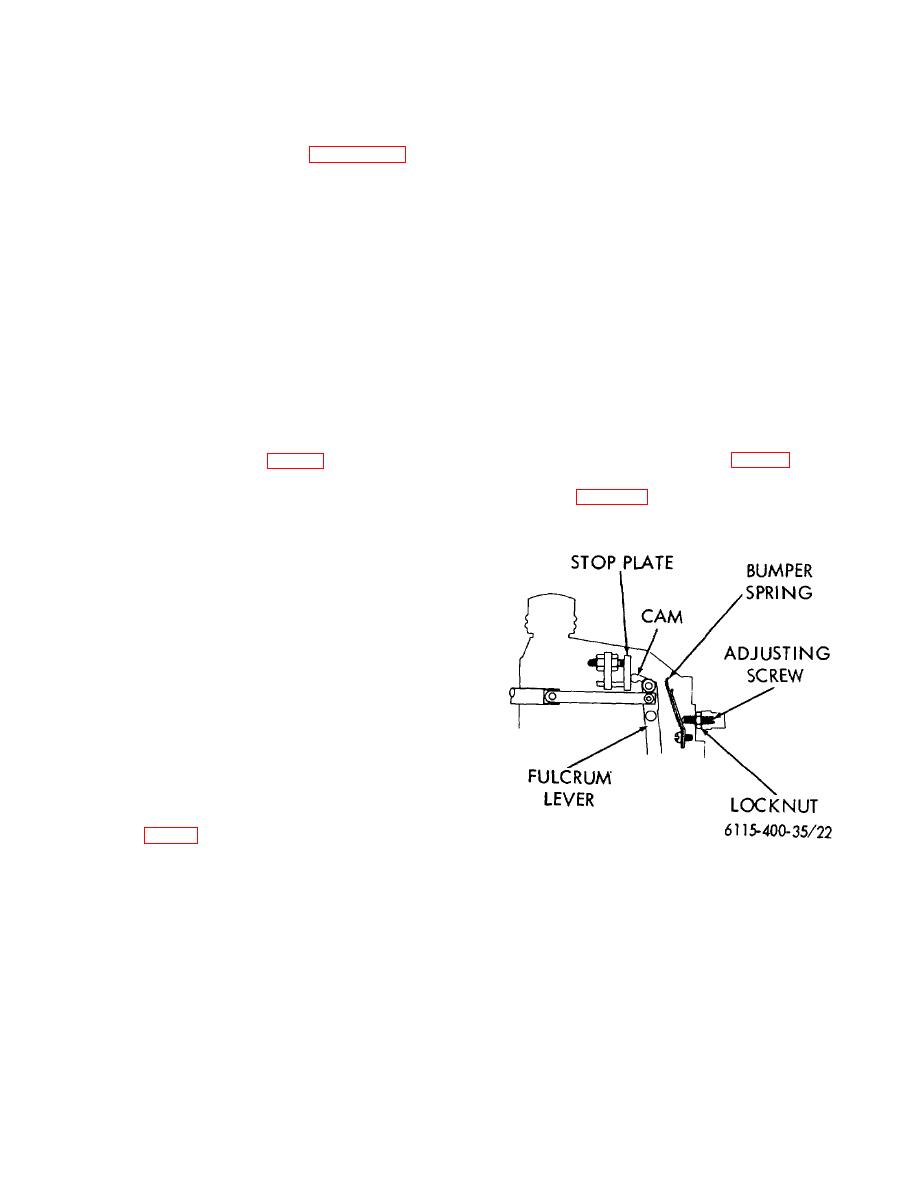

load rpm and adjust stop plate (68) to just

contact cam (See fig. 22). Then inscribe

line on the machined surface of governor

(1) Clamp pulley hub in a vise as shown in

housing with straight edge across front

face of stop plate.

with copper protectors.

(7) Record fuel delivery taken at this setting

and rpm.

(8) Check for torque control by reducing rpm

to 2/3 of full load speed.

Holding

operating lever in full load position, an

increased fuel delivery will result.

(9) With operating lever still in full load

position, increase rpm to high idle rpm.

The control rack should have moved into

decreased fuel delivery position and

reduced fuel approximately 1/4-1/5 of full

load quantity. Record delivery for same

number of strokes as taken at rated full

load rpm.

(10) With pump operating at high idle rpm as

set in step 9 (and operating lever in full

load position) turn in adjusting screw (See

the fulcrum lever. In the event that slight

oscillation is present in the fulcrum lever

Figure 22. Governor bumper spring adjustment.

at this higher rpm, screw in bumper spring

screw in this position with lock nut and

cap.

(11) The high and low idle setting can only be

approximated on the test stand, as the

actual idle settings must be made on the

engine.

54