TM 5-6115-400-35

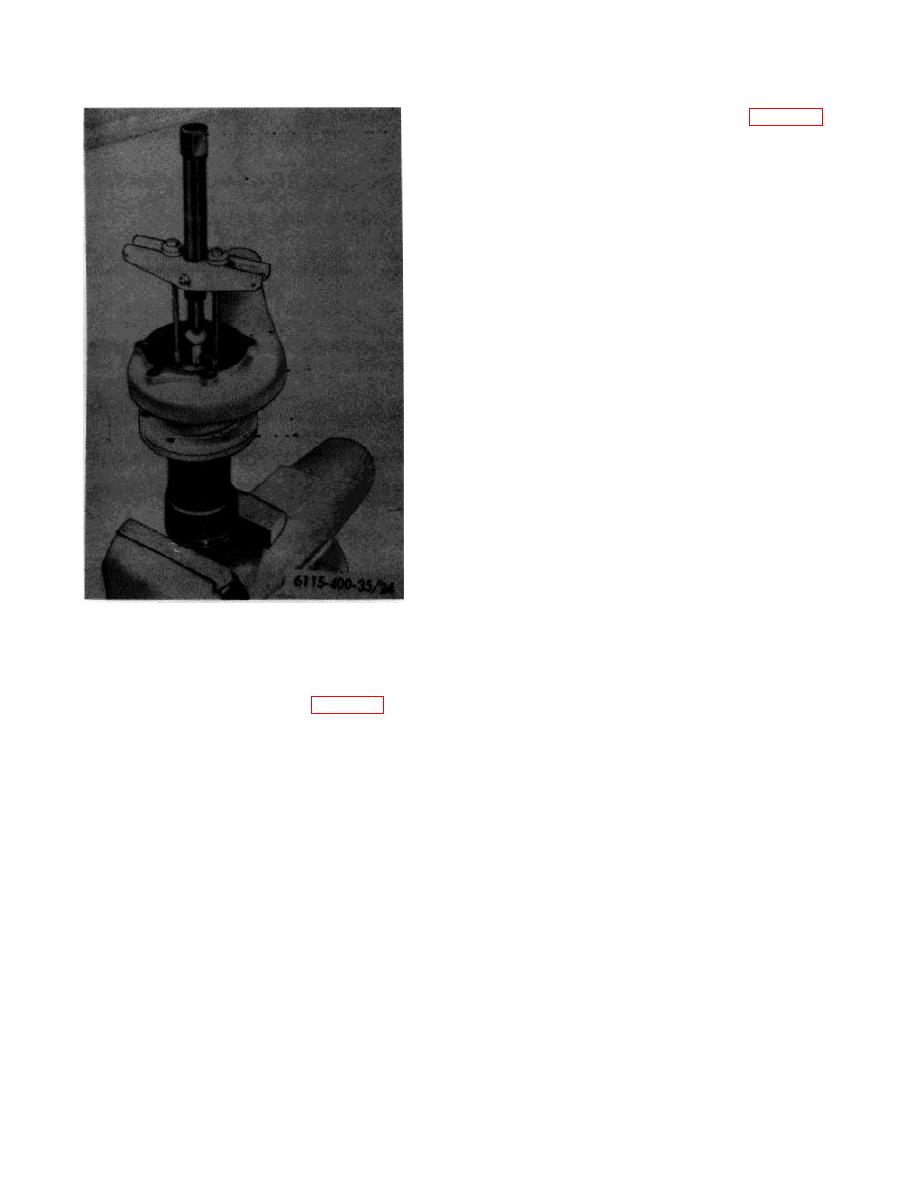

(9) Using tools as shown in figure 27, press

pulley hub onto shaft making sure that

key. is alined with keyway in pulley hub.

(10) Install washer and nut. Tighten nut to a

torque of 50 ft. lbs. Aline nearest slot in

nut with cross-drilled hole in shaft and

install cotter pin.

(11) Using a new gasket, position pump body,

with seals installed, on bearing sleeve,

alining the drilled stud holes, and securing

sleeve to body temporarily with a bolt and

nut to facilitate easier installation of

impeller on the pump shaft.

(12) If original impeller is to be reused, install

impeller as follows:

(a) Drive the old retaining pin from

impeller.

Note.

Make certain that ceramic sealing

ring bonded to impeller is thoroughly

cleaned before assembling. Use an

absorbent paper or lint-free cloth for

cleaning.

If thorough cleaning

cannot be accomplished this way,

use a solvent and then wipe clean.

DO NOT APPLY OIL OR GREASE TO

THE CERAMIC SEALING RING.

Figure 24. Pulling impeller from pump shaft.

(b) Start impeller on the pump shaft so

that drilled hole in impeller is turned

1800 from its original position and

(4) Press front ball bearing onto the shaft,

install impeller retaining nut; tighten

positioning bearing against shoulder of the

nut to 30 ft. lbs.

shaft. Install key in keyway of shaft.

torque and install cotter pin.

(5) Using tools as shown in figure 27, install

(c) Using a sharp 1/8 inch diameter drill

roller bearing in its bore in bearing sleeve.

inserted into drill hole in impeller,

Install snap ring.

drill hole in shaft until total depth of

(6) Install pump shaft and ball bearing as an

the hole is 29/32 inch.

Install

assembly into bearing sleeve by tapping

groove pin so that outer end of pin

on end of shaft with a soft hammer, using

is 1/16 inch below surface of

as little force as possible.

impeller and stake (or peen) pin in

Caution:

place.

Make sure that roller bearing race on

(13) If a new impeller is to be installed, install

shaft is alined with roller bearing

impeller as follows:

before tapping shaft and ball bearing

(a) Remove burrs from shaft bore of

into position.

impeller and start impeller on shaft

(7) Install snap ring.

so that drilled hole in impeller is

(8) Install front oil seal by tapping seal into

turned 180 from old groove pin

position with a soft hammer.

location. Install impeller retaining

Note.

nut, tighten to a torque of 30 ft. lbs.

Lightly coat outer diameter of the

and install cotter pin.

seal with sealing compound before

installing.

57