TM 5-6115-400-35

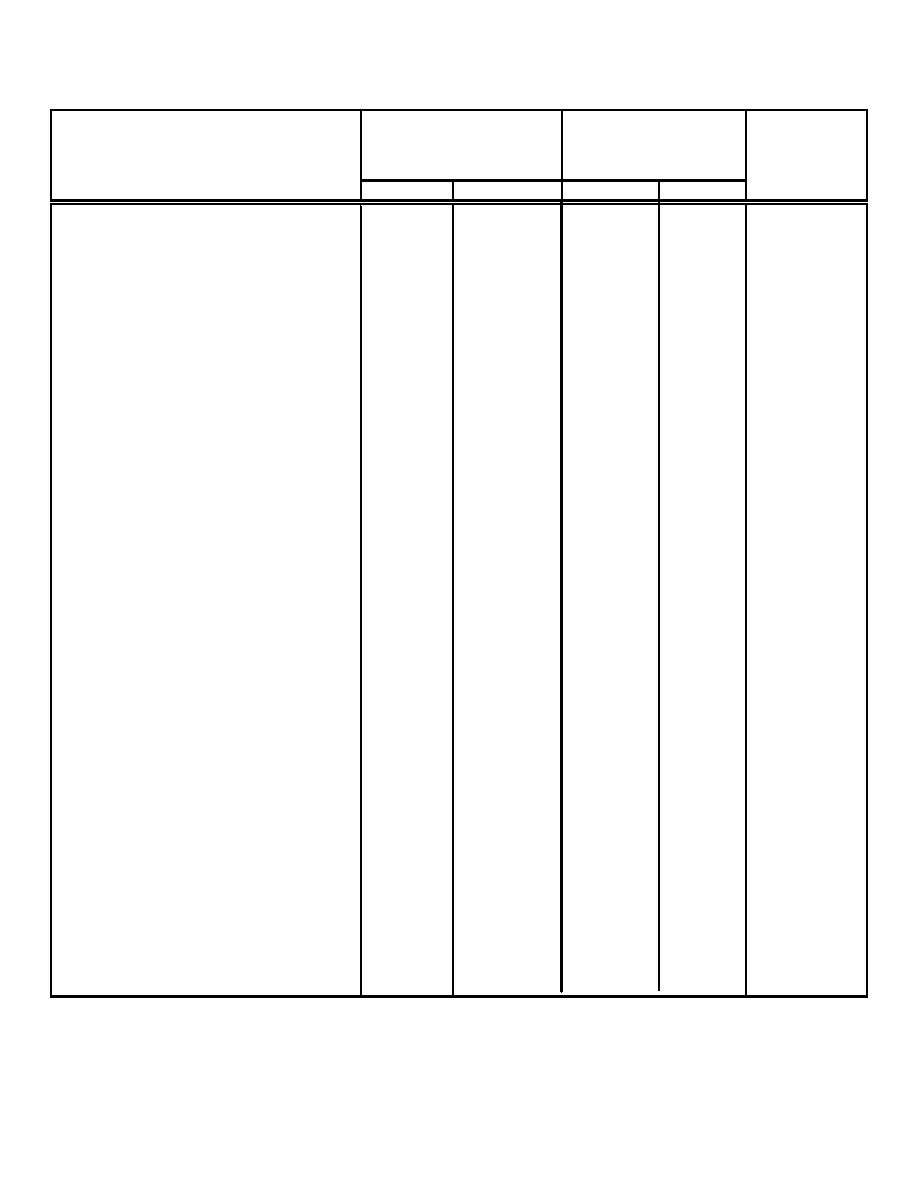

Table 1. Engine Repair and Replacement Standards-Continued

Manufacturer'

s

Maximum

Component

dimensions and

Desired

allowable

tolerance in

clearance

wear and

inches

clearance

Min.

Max.

Min.

Max.

Gap between ends

Top-compression ..........................................................

------------

------------

0.0210

0.0390

2nd-compression ..........................................................

------------

------------

0.0230

0.0410

3rd-compression ...........................................................

------------

------------

0.0230

0.0410

4th-oil control-ventilated w/spring ..................................

------------

------------

0.0130

0.0380

Clearance of rings in grooves

Top-compression ..........................................................

------------

------------

0.0040

0.0060

2nd-compression ..........................................................

------------

------------

0.0030

0.0050

3rd-compression ...........................................................

------------

------------

0.0030

0.0050

4th-oil control-ventilated w/spring ..................................

------------

------------

0.0015

0.0035

Crankshaft:

Journal diameter for connecting rods ............................

3.3725

3.3735

Journal diameter for main bearings ...............................

3.9950

3.9960

Width between connecting rod journal checks ..............

2.1235

2.1265

Width of main bearing journals

Front .........................................................................

2.9080

2.9680

Intermediate ..............................................................

2.0570

2.0670

Center .......................................................................

3.2500

3.2520

Rear ..........................................................................

2.5570

2.5670

Separate type thrust flanges-Available in

standard size and .005 in, .010 in., .015 in. oversize

Crankshaft end clearance .................................................

------------

------------

0.0070

0.0150

Crankshaft journals may be ground - .010 in.,

.020 in., .030 in., .040 in.

Fit of crankshaft front gear on crankshaft ..........................

------------

------------

0.0005

0.0025

...................................................................................

tight

Main bearings:

Number used-7

Type-Aluminum, steel backed

Main bearing-to-crankshaft clearance ......................... -

------------

------------

0.0021

0.0048

Inside diameter of bearings (bearings installed and

caps tightened to specified torque) ...............................

3.9981

3.9998

Diameter of crankshaft main bearing journals ...............

3.9950

3.9960

Length of front and rear bearings ..................................

1.9950

2.0050

Length of center bearing ...............................................

2.7460

2.7560

Length of intermediate bearing ......................................

1.4950

1.5050

Undersize bearings available for service-.010 in.,

.020 in., .030 in., .040 in.

Separate type thrust flanges-Available in

standard size and .005 in., .010 in., .015 in.

oversize

Standard wall thickness ...............................................

0.1876

0.1881

Torque for tightening main bearing capscrews

5/8 in.-U.N.C.

160-170 ft-lb

7/8 in.-U.N.C.

370-380 ft-lb

Connecting rod bearings

Type

Aluminum, steel backed

Inside diameter ..........................................................

3.3756

3.3771

Diameter of crankshaft connecting rod journal .........

3.3725

3.3735

Connecting rod bearing to crankshaft journal

vertical clearance (bearings installed and caps

tightened to specified torque) ....................................

------------

------------

0.0021

------------

0.0046

6