TM 5-6115-400-35

rqr), No. 6 vinyl glass

Duty classification . .............Continuous

saturated sleeving,

Degree of enclosure ...........Full, dripproof, guarded

grade

d. Generator Repair and Replacement Standards.

C1, 10 ft. long. Lead

Revolving field:

insulators (9 rqr), No.

Number of coils ..................4

4 vinyl glass saturated

Turns per coil .....................50

sleeving, grade C1, 2 ft.

Total turns ..........................200

long. Tie cord, No. 8

Wire size ............................No. 7 AWG (American

cord, 8 ft long.

Wire Gage) 7 square

Dipping compounds ............Varnish, MIL-I-24092-

"FE"

class 155, type M

Type of wire .......................MIL-W-583C-class 155,

Dipping and baking .............Dip completely wound

type L-2

procedures.

stator in varnish and

Coil connection ..................Series

drain well. Bake at

Insulating materials ............Resin treatment per wind-

300 .

F

for 4 hrs.

ing of wire, Ret. #660

Repeat

P-4818. Lead insulators

dipping procedure, and

(4 rqr), No. 11 vinyl

bake at 300 . for an

F

glass saturated sleeving,

additional 4 hrs. Repeat

1 ft. long. Lead con-

dipping procedure, and

nection insulators (8

bake at 300'F. for 12

rqr), No. 6 vinyl glass

hrs.

saturated sleeving, 1/2

e. Nut and Bolt Torque Data.

ft. long. Lead connec-

Main bearing capscrews

tion tie, glass untreated

5/8 in. U. N. C. ................160-170 ft-lb

sleeving, 1 1/2 ft. long.

7/8 in. U. N. C. ................370-380 ft-lb

Shaft insulator.

Connecting rod nuts ...........190-200 ft-lb

Dipping compounds ............Varnish, MIL-I-24092-

Cylinder head capscrews

class 165, type M

5/8 in.... ...........................180-185 ft-lb

Dipping and baking .............After each layer of wire,

3/4 in. ..............................260-275 ft-lb

procedures. ......................brush on resin. Bake

Fuel injection nozzle ...........60-80 ft-lb

completely wound

retaining nut.

revolving field at 300 .

F

Nozzle holder clamp nuts ...21-24 ft-lb

for 10 hrs. Dip revolving

Crankshaft pulley ................250-260 ft-lb

field in specified varnish.

retaining nut.

Stator:

Front support bracket .. .......95-105 ft-lb

Number of poles .................4

Timing gear housing cover

Number of slots ..................72

capscrews

Number of coils ..................72

3/8 in. ..............................28-33 ft-lb

Coil span ............................1-13

1/2 in. ..............................68-73 ft-lb

Turns per coil .....................2

Piston cooling oil jets ..........35 ft-lb

Wire size ............................12, No. 14 round, AWG

Flywheel bolt nuts ..............160-170 ft-lb

Type of wire ........................ (MILW-583A) class 155,

type L-2

Insulating materials ............Slot insulators (72 rqr),

lists

manufacturer's

sizes,

tolerances,

desired

coil separators (72 rqr),

clearances, and maximum allowable wear and

cell covers (72 rqr),

clearances.

phase insulators (12

rqr), lead insulators (12

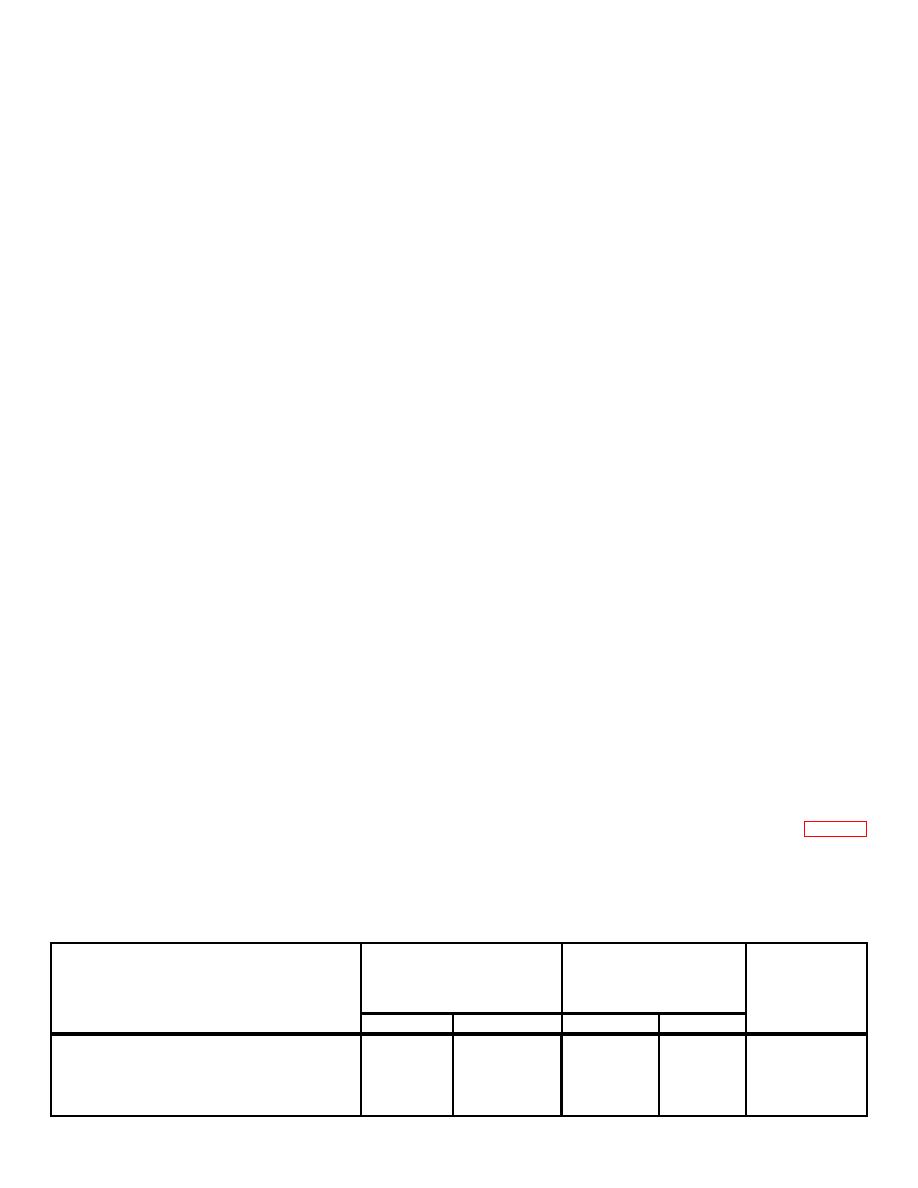

Table 1. Engine Repair and Replacement Standards

Manufacturer'

s

Maximum

Component

dimensions and

Desired

allowable

tolerance in

clearance

wear and

inches

clearance

Min.

Max.

Min.

Max.

Cylinder sleeve:

Type Replaceable wet inside diameter ..........................

5.2510

5.2520

Allowable cylinder wall taper ..........................................

------------

------------

------------

------------

0.0015

Allowable out-of-round when installed ............................

------------

------------

------------

------------

0.0015

Piston skirt to cylinder sleeve clearance ........................

-------------

------------

0.0070

0.0090

4