TM 9-6115-604-34

NAVFAC P-8-633-34

10-6. TRANSDUCER TESTS. This paragraph contains detailed on-equipment and bench tests for transducers AMT,

A103. PFT, and WMT. Not all of the transducers have both on equipment and bench tests.

a.

Current Transducer AMT On Equipment Test.

WARNING

Do not work on energized equipment Generator set must be shut down.

Transducer voltage and current Inputs and outputs are hazardous.

Performing maintenance on energized transducers may result In Injury or

death.

(1)

With the generator set shut down, set LOCAL REMOTE switch S2 to LOCAL and AMMETER switch S114

to “1”.

(2)

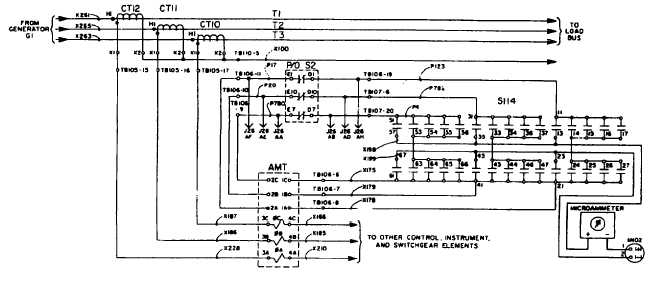

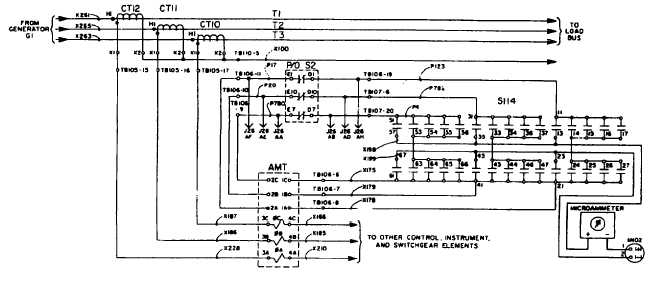

Open upper cabinet B door. See Figure 10-9. Connect a microammeter into the line connected to AC

AMPERES meter M102 terminal "I".

(3)

With the generator set connected to a known, balanced load, start the generator set and close it onto the

load bus in accordance with the Operator and Organizational Maintenance Manual.

(4)

Record the microampere reading at each AMMETER switch setting, i.e., 1", "2, and "X.

Figure 10-9. Current Transducer AMT, On Equipment Test Setup

(5)

Shut down the generator set in accordance with the Operator and Organizational Maintenance Manual.

(6)

Compute an expected microammeter reading using the following formula:

æAe =Lk

where æAe is the expected microammeter reading in microamperes and Lk is the known load in the

generator set in kilowatts.

(7)

Compare readings recorded in step (4), above, with expected readings computed in step (6), above.

(a)

actual readings agree with expected reading within::2 microamperes, then transducer AMT is

functioning properly and AC AMPERES meter Ml 02 should be giving accurate readings at 2 percent

accuracy or better.

(b)

If actual readings differ with expected readings by more than 2 microamperes, then transducer AMT

may be defective. Proceed as follows:

1 Remove transducer AMT in accordance with step b, below.

2 Bench test transducer AMT in accordance with step c, below.

3 Reinstall transducer AMT (or replace, i defective) in accordance with step d, below.

10-18