TM 9-6115-604-34

NAVFAC P-8-633-34

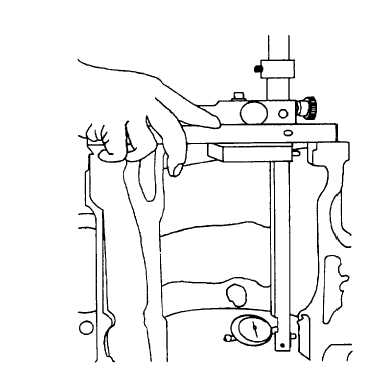

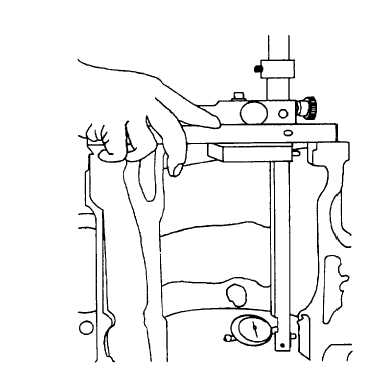

Figure 9-57. Measuring Lower Liner Bore Concentricity Using ST-1252

(6)

Check the cylinder block lower liner bore entry chamfer. Repair the chamfer if it is pitted or eroded to the

extent that it would cut the packings or prevent proper liner installation.

(7)

Temporarily install the main bearing caps. Using the centering rings, bore bar, and checking rings from

boring tool kit 3375059, check the main bearing bores for size, taper, out-of-round, and alignment. If any

main bearing cap is found to be distorted, install and line bore a new cap or caps.

(8)

Inspect the thrust bearing surface at the rear of the cylinder block for scoring or grooving. Refinish the

thrust surface if it is grooved, or if it is scored over 0.003 inch (0.07 mm) deep.

(9)

Check for damaged or eroded water holes. Install sleeves to repair eroded water holes.

(10)

Inspect the cylinder block head gasket surface for flatness using a straight edge and feeler gage. The

flatness shall not vary over 0.002 inch (0.05 mm). Up to 0.010 inch (0.25 mm) may be removed from

cylinder block head surface to restore flatness or remove defects.

9-101