TM 9-6115-604-34

NAVFAC P-8-633-34

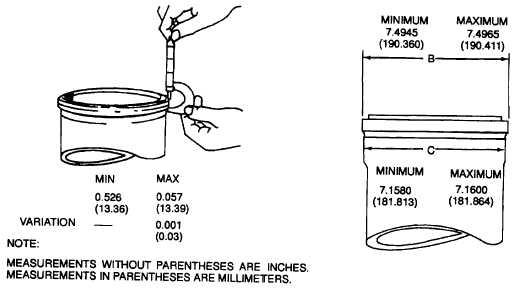

NOTE

Two types of cylinder liners may be encountered: On engines manufactured before July 1980,

to engine number 33103621 the liners press into the top counterbore of the cylinder block (B,

Figure 9-35). On later engines, the liners press into the secondary bore of the cylinderblock

(C, Figure 9-35). Accept or reject the cylinder liner in accordance to either step (4) or step (5),

below, as applicable.

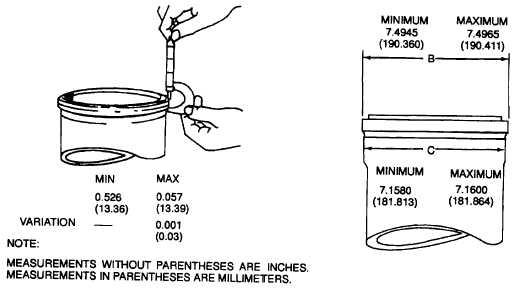

(4)

Check the outer diameter of the cylinder liner flange (B, Figure 9-35). Replace the liner if the diameter is not in

accordance with the dimensions given in Figure 9-35.

(5)

Check the diameter of the cylinder liner at C, Figure 9-35. Replace the liner if the diameter is not in accordance

with the dimensions given in Figure 9-35.

(6)

Check the liner for cracks using magnetic particle inspection in accordance with MIL-L-6868; pay particular

attention to the comer area under the flange. Replace the liner if cracked.

(7)

Check the cylinder block liner counterbore, secondary liner bore, and lower liner bore in accordance with

paragraph 9-31.

(8)

Clean and prepare cylinder block for liner installation in accordance with paragraph 9-31.

c. Clean.

CAUTION

To avoid scratching the bore, use a fiber brush only. DO NOT use a wire brush to dean the

bore.

(1)

Clean each new or acceptable liner with detergent and hot water. Scrub the bore thoroughly with detergent

solution and a bristle brush, and rinse with hot water.

(2)

Oil the bore with dean lubricating oil, and let it stand for 5 minutes.

(3)

Wipe the bore with dean white paper towels, and examine the towels for a gray or black deposit I a gray or black

deposit is noted, repeat the oiling and wiping procedure until the towels remain dean after wiping.

(4)

Re-oil the bore, and store the liner in a dean plastic bag until ready for installation.

Figure 9-35. Cylinder Liner Measurements

9-68