TM 9-6115-604-34

NAVFAC P-8-633-34

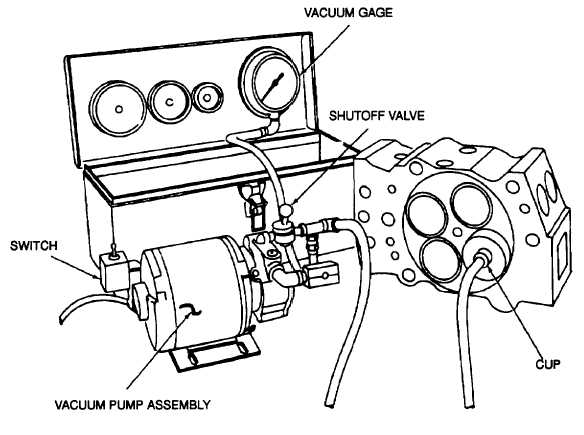

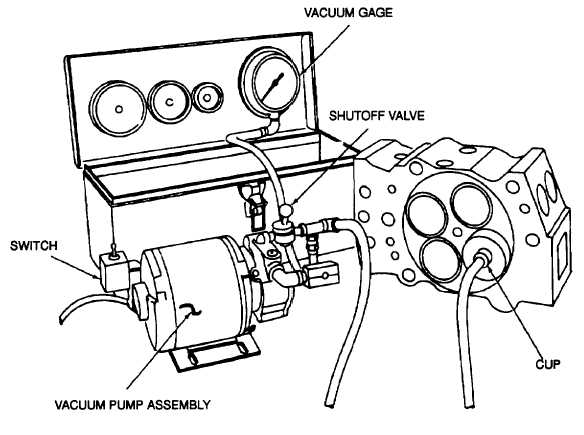

Figure 9-11. Vacuum Testing Valve Seats Using ST-1257

(4)

If necessary, add a maximum of two valve spring shims under the valve spring guide (4), to adjust the

assembled valve spring height to not over 2.470 inches (62.74 mm).

(5)

If the correct valve spring assembled height cannot be obtained with two shims, the valve, the seat insert,

or both the valve and the seat insert must be replaced. See paragraph 9-11 for valve seal insert

replacement procedures.

(6)

Remove locks (1), seats (2), spring (3), and guide (4). Install shims (if necessary), guide (4), spring (3),

and seat (2) over valve (5 or 6).

(7)

Using valve spring compressor ST-448-6, compress spring (3), and install new locks (1).

(8)

Install the remaining valves using steps (1) through (6), above.

f.

Vacuum Test. Check for satisfactory valve sealing using valve vacuum tester ST-1 257, as follows (see Figure

9-11):

CAUTION

Never vacuum test a cylinder head with the injectors installed The installation of injectors

while the head is removed from the block could cause misalignment to the halves In the valve

seat area resulting In leakage during testing. This leakage would not necessarily occur during

actual engine operation.

(1)

Before testing for valve leakage, check vacuum tester ST-1257, for leaks as follows:

9-17