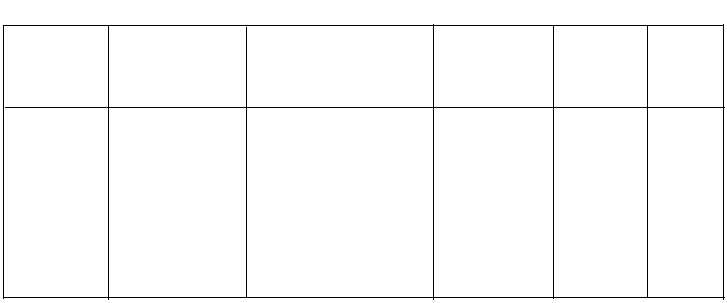

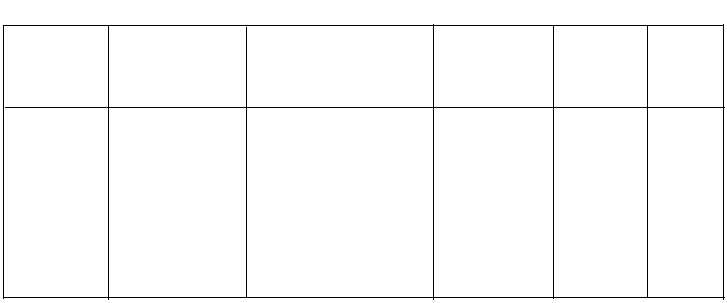

QTY

REQUIRED

FOR

INITIAL

OPERATION

QTY

REQUIRED

FOR 8

HOURS

OPERATION

ARMY TM 9-611560412

NAVY NAVFAC P-833-12

Table 3-1. Consumable Operating and Maintenance Supplies (Continued)

Parts,

6850-00-281-1985

P-D-680, Dry

(0)

(0)

(18)

Cleaning

Cleaning Solvent,

1.0 gal (3.8 L)

6850-00-285-8011

P-D-680, Dry

(0)

(0)

(18)

Cleaning Solvent,

55 gal (208 L)

Parts,

9150-01-023-3934

VV-P-236,

(0)

(0)

(19)

Assembly

Petrolatum

NOTES

(1)

See Federal Supply Catalog C9100-1L for additional requisitioning data.

(2)

See Federal Supply Catalog C6800-1 L for additional requisitioning data

(3)

Fuel tank capacity is 130 gallons (492 L)

(4)

Average fuel consumption Is 55 gallons (208 L) per hour 8 hours continuous duty will require approximately 440

gallons (1665 L).

(5)

One tank, if required, for cold weather starting.

(6)

Crankcase capacity Is 30 gallons (113 L) plus 6 gallons (23 L) for the filters.

(7)

Total cooling system capacity Is 91 3 gallons (345 6 L), 31 25 gallons (118 3 L) for the engine block and 51.8

gallons (196 1 L) for the radiator.

(8)

See Figure 3-2 for lube points

(9)

See Figure 3-2 for grade, application, and replenishment intervals

(10)

Each battery requires 4.1 gallons (15.5 L) of electrolyte.

(11)

One fuel strainer element is required at any given time. Replace strainer tube every 300 hours, continuous duty

cycle or every 6 months at standby duty

(12)

Four transfer pump fuel filter and two engine mounted fuel filter elements are required at any given time. Replace

transfer pump strainer every 300 hours for continuous duty or every 6 months with generator set at standby

duty

(13)

Two oil by-pass filters and four full-flow oil filters are used at any given time. Replace all oil filter elements every

300 hours for continuous generator set duty or every 6 months for standby duty.

(14)

Two primary and two safety air cleaner elements are used at any given time Service the primary elements

whenever the air restriction indicators turn amber or red The primary elements may be cleaned and reused six

times (or after two years, whichever comes first), after which they should be replaced Do not attempt to clean the

safety elements. Replace the safety elements after the primary elements have been changed three times.

(15)

New generator set engines are equipped with four DCA precharge water filter canisters which should be replaced

with the DCA service filters (WF 2010) at the first oil change after initial operation. Thereafter, replace the DCA

service elements after 250 hours continuous duty or 6 months standby duty, whichever comes first.

(16)

Precharge new engine coolant whenever the cooling system is drained and cleaned. The DCA-4L precharge

direct chemical additive Is used for this purpose and is compatible with either plain or antifreeze-treated water

(except Dowtherm 209) Use 16 pints of DCA-4L additive to precharge the entire generator set cooling system (74

gallons (280L), approximate). Use the precharge additive, also when storing make-up coolant in bulk.

(17)

The DCA coolant test kit is used to check DCA concentration In the engine coolant. Draw coolant sample every 6

months and use the test kit to check effectivity of coolant filtering and DCA treatment.

COMPONENT

APPLICATION

NATIONAL STOCK

NUMBER

DESCRIPTION

NOTES

3-3