TM5-6115-593-34

NAVFAC P-8-631-34

TO-35C2-3-463-2

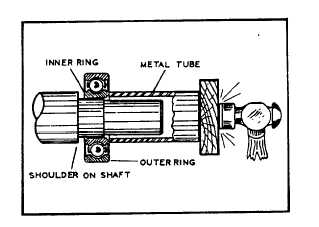

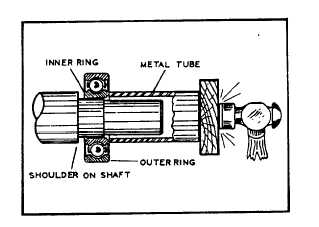

temperature of from 220 to 250F (103 to 121°C) in a

clean thermostatically controlled oven. Start the heated

bearing into the shaft. Then use a fiber or soft metal tube

to tap bearing into place. (See figure 11-16.) Make

certain that pressure is applied only to the bearing inner

ring.

Figure 11-16. Install Bearing on Generator Shaft

(b) Press bearing onto shaft until inner ring is

against bearing shoulder on the shaft.

Continue assembly after

the bearing has cooled.

(c) Using a crane, install endbell (85) and PMG

stator and exciter assembly, over generator

shaft.

(d)

Install screw (80) and washers (81).

(e) Install screws and lockwashers (82 and 83)

attaching bearing cap (84) to endbell (85).

(f)

Line up lockwasher (87) and tighten nut (86)

to secure bearing.

(g) Tighten setscrew (52) in exciter rotor (38).

(h)

Install PMG rotor (37) with pin (36), scres

(35), and washer (34).

(i)

Replace cover (30) with screws (26 and 28),

washers (29), and nuts (27).

11-10. DRIVE PLATE ASSEMBLY.

a.

General. The generator shaft is directly

driven by the engine shaft through the drive

plate assembly, figure 11-17. The coupling

compensates for misalignment between the

two shafts to eliminate injurious stress on

the connection components.

b.

Replacement.

(1)

Removal. Remove drive plate

assembly (59, figure 11-3) as follows:

(a)

Remove cover (63) and cover (67)

by removing screws (64), washer

(66), and nut (65).

(b)

Remove screws attaching drive

plate assembly to engine flywheel.

(See figure 11-18.)

(c)

Loosen setscrew (60) in coupling

hub (61).

(d)

Push drive plate assembly as far as

possible towards the generator fan,

in order to gain access to the hub

screws (57).

(e)

Remove screws (57) by

straightening locking plate (58).

Remove drive plate assembly.

(2)

Replacement. Install drive plate assembly

as follows:

(a)

Locate drive plate assembly onto hub (61)

11-27