4-37

TM5-6115-585-12

NAVFAC P-8-262-12

TO-35C2-3-455-1

TM-05684C-12

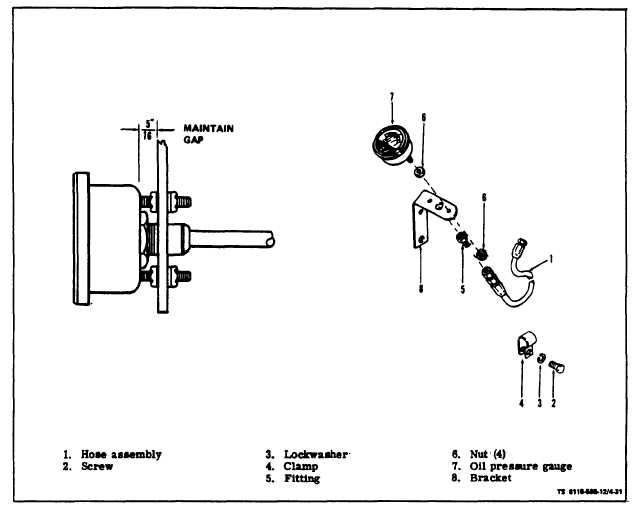

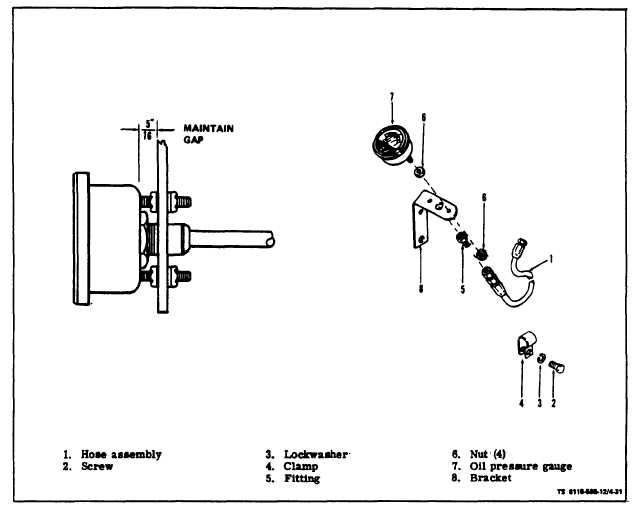

Figure 4-31. Replacing Oil Pressure Gauge

4-33. OIL PRESSURE GAUGE.

On ASK equipped generators, remove oil access door.

a. Test. Attach a pressure gauge of known accuracy

between flexible oil line and unit pressure gauge. Operate unit

for 1/2 hour and check that both gauges read the same. At

rated rpm the normal oil pressure range is 20 to 45 psi which

is dependent on sir and engine temperature, grade of oil, and

wear tolerances on the engine. If the unit pressure gauge is

in error by more than 5 lb, replace.

b. Remove (see figure 4-31). Disconnect and drain

oil line (1) to Oil pressure gauge (7). Remove screw

(2),

lockwasher (3), clamp (4) and remove oil pres-

sure gauge and bracket. Remove fitting (5) and nuts

(6) attaching gauge (7) to mounting bracket (8) and

remove gauge (7).

c. Replace. Install oil pressure gauge (7) on mount-

ing bracket (8) with nuts (6) two on each side of

bracket (6). Maintain gap between gauge and bracket

as indicated on figure 4-31. Position oil pressure

gauge and bracket on engine and install clamp (4),

lockwasher (3) and screw (2). Connect and tighten

oil line (1).