TM 5-6115-584-12

NAVFAC P-8-622-12

TO-35C2-3-456-1

TM-05682C-12

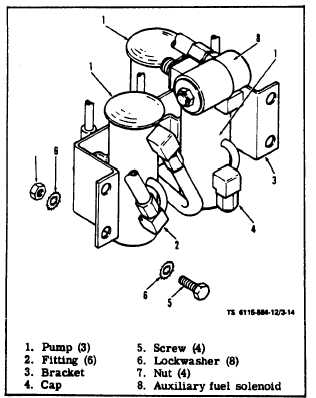

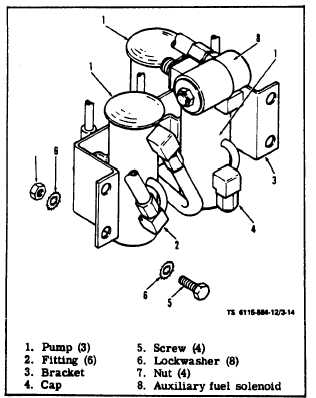

(3) Fuel Pump Assemblies (Three) (see figure

3-14). Inspect fuel pumps (1) for dents or other phys-

ical damage. Check for leaks especially around hose

assembly fittings (2). Check that fuel pumps are se-

curely attached to mounting bracket (3) and that

mounting bracket is securely attached to bracket sup-

port on skid-base. Inspect electrical leads to fuel

pumps to see that wires and connectors are not

broken, frayed, or damaged. Check that connectors

are tightly connected. Check that cap (4) on auxiliary

fuel pump inlet is securely in place when unit is not

being run from auxiliary fuel supply,

(4) Fuel Hoses. Inspect fuel hoses (2, 3 and 4,

figure 3-13) for leaks or physical damage. Check to

see that fuel hose fittings are securely tightened in

place.

b. Service. On ASK equipped generators, remove fuel

filters access door.

(1) Fuel Filter Assemblies (see figure 3-13). Daily

before operation, open drain valves (1) and drain water

and sediment from filter assemblies.

(2) Fuel Strainer Assembly. Daily, before and after

operation, open drain valves (1) and drain water and sedi-

ment from strainer assembly (11).

Figure 3-14. Fuel Pump Assembly

3-20

Change 7

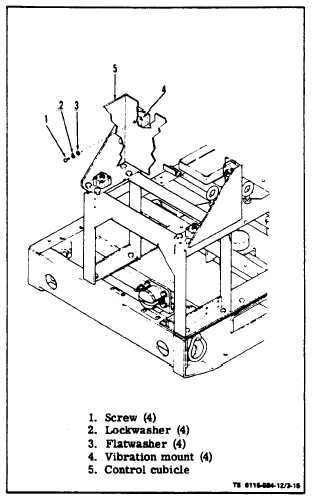

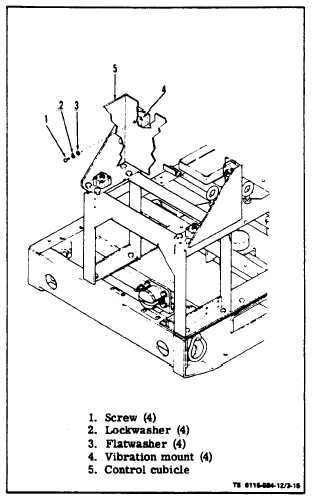

Figure 3-15. Control Cubicle Support Assembly

3-21. CONTROL CUBICLE SUPPORT ASSEMBLY,

SPEED CONTROL AND ENGINE CONTROL

WIRING HARNESS.

a. Inspect.

(1) Vibration Mounts (Four) (see figure 3-15).

Inspect vibration mounts for deterioration or physi-

cal damage. Inspect mounts to see that they are free

of dtrt, fuel, or oil. Check to see that mounts are

securely attached to control cubicle support on skid-

base. If mounts are faulty, refer to higher level of

maintenance.

(2) Engine Control Wiring Harness Assembly. On ASK

aquipped generator, open or remove all access doors. Inspect

wiring harness for broken or frayed wires. Check for wires with

damaged or deteriorated insulation. Check that all connectors and

terminals are ciean and tight.

(3) Speed Control Assembly (see fiiure 3-16). On ASK

equipped generators lift motor speed control flap. Inspect to see

that speed control is firmly attached to unit. Check that speed

control moves in and out freely. If speed control is loose, refer to

higher level maintenance.