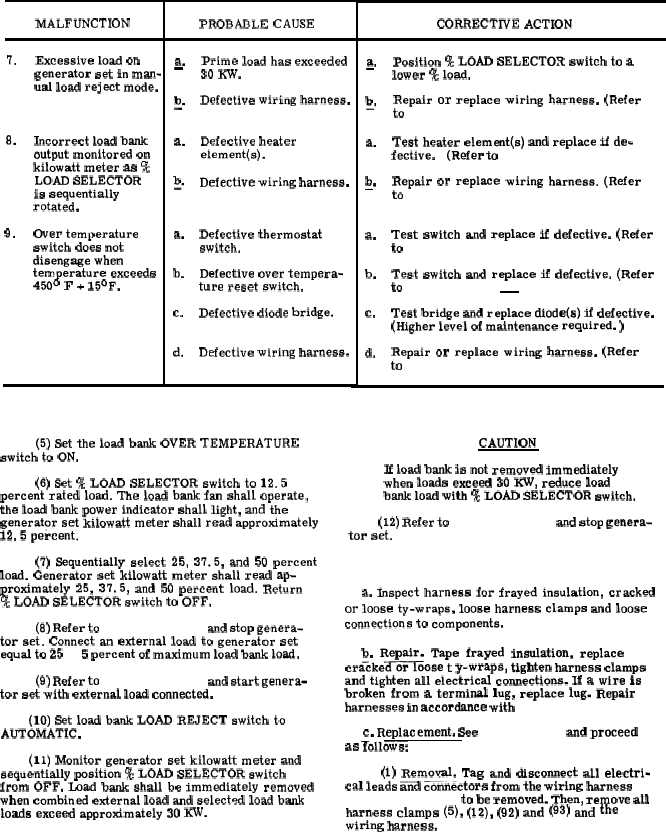

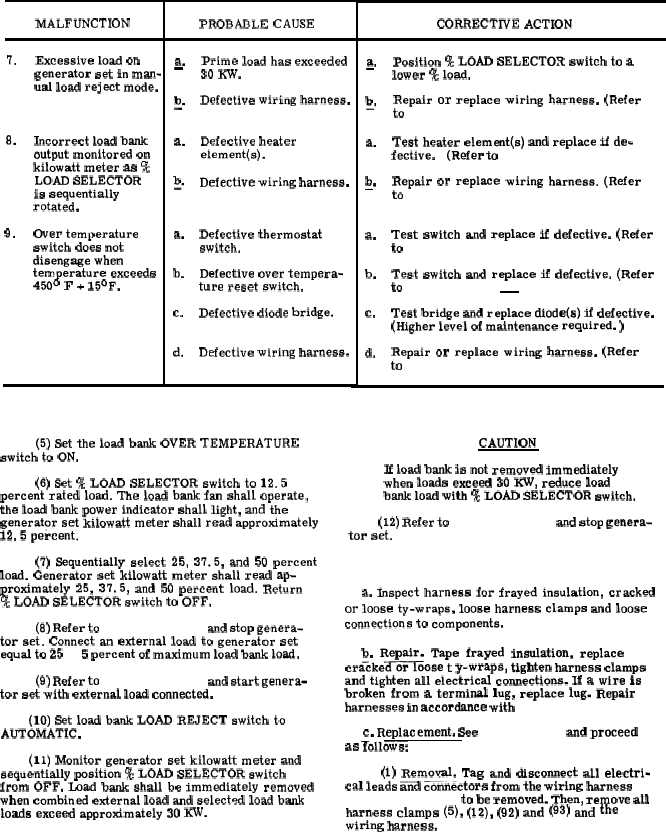

MALFUNCTION

7.

8,

9.

Excessive load on

generator set in man-

ual load reject mode.

Incorrect load bank

output monitored on

kilowatt meter as %

LOAD SELECTOR

is sequentially

rotated.

Over temperature

switch does not

disengage when

temperature exceeds

450° F + 15°F.

Table 4-8. Load Bank Troubleshooting (Cont)

CORRECTIVE ACTION

PROBABLE CAUSE

a.

Prime load has exceeded

—

30 Kw.

b

Defective wiring harness.

-“

a.

Defective heater

element(s).

b

Defective wiring harness.

-“

a.

Defective thermostat

switch.

b.

Defective over tempera-

ture reset switch.

c.

Defective diode bridge.

d,

Defective wiring harness.

(5) Set the load bank OVER TEMPERATURE

switch to ON.

(6) Set % LOAD SELECTOR switch to 12.5

percent rated load. The load bank fan shall operate,

the load bank power indicator shall light, and the

generator set kilowatt meter shall read approximately

12.5 percent.

(7) Sequentially select 25, 37.5, and 50 percent

load. Generator set kilowatt meter shall read ap-

proximately 25, 37.5, and 50 percent load. Return

% LOAD SELECTOR switch to OFF.

(8) Refer to paragraph 2-13 and stop genera-

tor set. Connect an external load to generator set

equal to 25 ± 5 percent of maximum Ioad bank load.

(9) Refer to paragraph 2-12 and start genera-

tor set with external load connected.

(10) Set load bank LOAD REJECT switch to

AUTOMATIC.

(11) Monitor generator set kilowatt meter and

sequentially position % LOAD SELECTOR switch

from OFF. Load bank shall be immediately removed

when combined external load and selected load bank

loads exceed approximately 30 KW.

4-38

a.

—

b-“

a.

b-“

a.

b.

c.

d.

Position ‘% LOAD SELECTOR switch to a

lower % load.

Repair or replace wiring harness. (Refer

to paragraph 4-43.)

Test heater element(s) and replace if de-

fective.

(Refer to paragraph 4-48.)

Repair or replace wiring harness. (Refer

to paragraph 4-43.)

Test switch and replace if defective. (Refer

to paragraph 4-47.)

Test switch and replace if defective. (Refer

to paragraph 4-44 d .)

Test bridge and replace diode(s) if defective.

(Higher level of maintenance required. )

Repair or replace wiring harness. (Refer

to paragraph 4-43.)

CAUTION

If load bank is not removed immediately

when loads exceed 30 KW, reduce load

bank load with ‘% LOAD SELECTOR switch.

(12) Refer to paragraph 2-13 and stop genera-

tor set.

4-43. Wiring Harness. (Figure 4-16)

a. Inspect harness for frayed insulation, cracked

or loose ty-wraps, loose harness clamps and loose

connections to components.

b. Repair. Tape frayed insulation, replace

cra%ke=oose t y-wraps, tighten harness clamps

and tighten all electrical connections. If a wire is

broken from a terminal lug, replace lug. Repair

harnesses in accordance with para 3-139.

C. Replacement. See f i g u r e 4 - 1 4 and proceed

as Tolloww.

(1) Removal. Tag and disconnect all electri-

cal leads and connectors from the wiring harness (7

or 94, fig. 4-14) to be removed. The% remove all

harness clamps (5), (12), (92) and (93) and the

wiring harness.