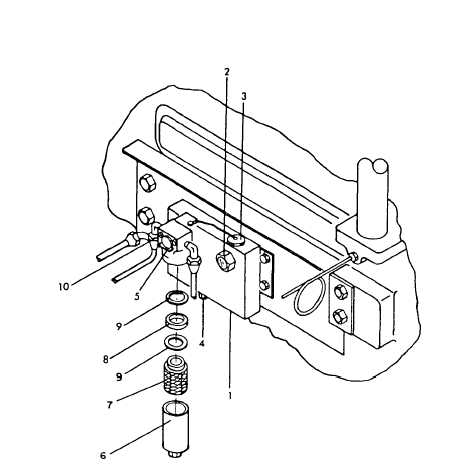

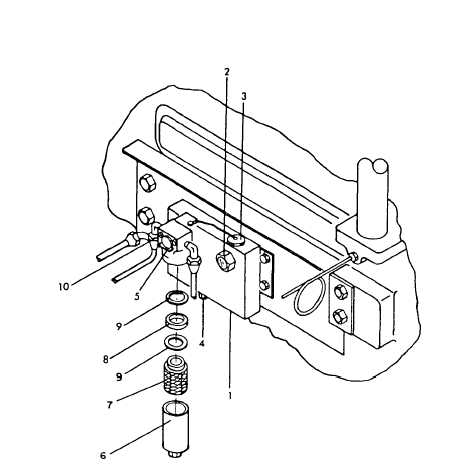

1. Hydraulic sump

6. Filter body

2. Sight glass

7. Filter element

3. Filler cap

8. Preformed packing

4. Drain plug

9. Backup rings

5. Lockwire

10. Header

Figure 3-8. Hydraulic Sump and Filter (MEP105A)

3-52. Oil Level Gage and Filler Inspection.

See figure 3-2 and proceed as follows:

a. Inspect oil level gage legibility of marking, loose

fitting and other damage.

b. Inspect oil filler cap for secure fitting.

c. Inspect seal on oil filler cap for excessive wear, and

other damage.

d. Inspect oil filler for cracks, loose mounting, and other

damage.

3-53. Starter Assembly Inspection.

Inspect starter assembly for cracks, dents, loose, damaged or

missing parts, loose mounting, loose electrical connections, and

other damage.

3-54. Oil Pressure Transmitter Inspection.

Inspect transmitter (18, fig. 3-3) for leaks, cracks, loose mounting,

loose electrical connection and other damage.

3-55. Lube Oil Filter Assemblies Inspection.

Inspect lube oil filters (fig. 3-3) for leaks, cracks, breaks, dents

and other damage.

3-18

Change 11