TM 5-6115-465-34

T035C2-3-446-2

NAVFAC P-8-625-34

TM 06858B/06859D-34

(1) If the FL - NL or NL - FL transient ex-

NOTE

ceeds 1-1/2 percent of rated speed and/or does not

If the drift in paragraph (4) is excessive,

re-establish stable engine operating conditions with-

realign the control unit following the

in one second, realign the control unit in accord-

procedure outlined in paragraph 4- 7j.

ance with paragraph 4-7j. Also follow this proced-

ure if the engine speed hunts. If the set cannot be

(5) At constant ambient temperature, constant

stabilized, check sockets A and B of plug P-21 (fig-

load, constant voltage and constant barometric pres-

ure 4-38) for 24 Vdc (A is positive).

sure, the set frequency should remain within a band-

(2) If the engine speed increase to above

width of 1 percent of rated frequency far a period of

4 hours. If this bandwidth has been exceeded, re-

nominal operating speed, check sockets A and B of

align the control unit in accordance with paragraph

P-17 (figure 4-38) for 120 Vat. If it is missing,

troubleshoot the generator set wiring. Refer to

schematic and troubleshooting diagram plates located

on inside of left and right engine compartment doors

(6) If the preceeding solutions to the specific

problem do not resolve the problems, replace and

repair the control unit, actuator (paragraph 3-42).

of the frequency adjusting circuit consisting of R4

(250 ohms) rheostat R1 frequency adjust (500 ohms)

or load measuring unit (paragraph 4-6) as required.

and R6 (250 ohms) fixed resistor. Measure the

total circuit resistance across N and T of harness

Removal.

c.

plug P17 (figure 4-38). The circuit resistance should

(1) Tag and disconnect electrical connectors

be 1000 ohms (5 percent tolerance). After testing for

to governor control unit.

correct total resistance, test the operation of the

frequent y adjust rheostat by connecting an ohmmeter

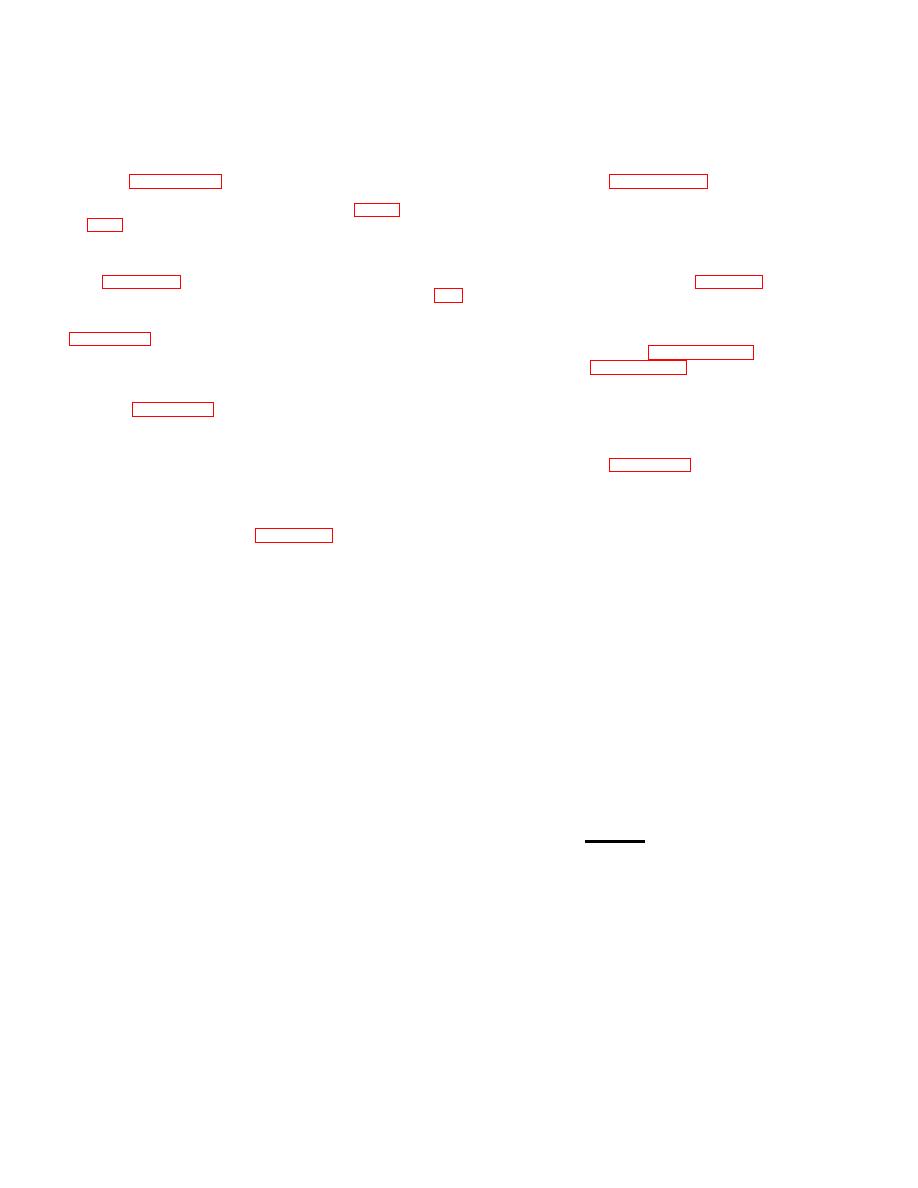

(2) Remove nuts (1, figure 4-15), lockwashers

across pins M and T and revolving the frequency ad-

(2), nuts (3), lockwashers (4) and bracket (5), threaded

just rheostat trough its entire travel. The resistance

should vary from 750 ohms to 250 ohms. Repeat this

rod (6) and lift governor control unit from mounting

bracket.

procedure using the ohmmeter across pins M and N

of the harness plug. If the problem persists, check

sockets A and B of plug P-21 (figure 4-38) for 24 Vdc

d.

Disassembly.

(A is positive).

(1) Disassemble governor control unit (7

(3) If the engine speed remains below the

through 58) only as is necessary for inspection, test-

ing, and replacement of parts.

nominal operating speed, adjust R 1. If there is no

improvement, check the resistance of the frequency

adjust circuit. Disconnect P-17 and check the resis-

NOTE

tance of the frequency adjust circuit consisting of

Disassembly and repair of the electric gov-

R4 (250 OhmS ) fixed resistor, R1 frequency adjust

rheostat (500 ohms ) and R5 (250 ohms, 5 percent)

ernor control unit at the field level is re-

fixed resistor. Measure the total circuit resistance

stricted to removal of the cover, connectors,

across N and T of harness plug P-17. The circuit

potentiometers and test jacks. Further dis-

resistance should be 1000 ohms (5 percent tolerance).

assembly requires unpotting which can be

After testing for correct total resistance, test the

performed by depot maintenance personnel

operation of the frequency adjust potentiometer by

only.

connecting an ohmmeter across pins M and T and re-

volving the travel. The resistance should vary from

(2) Remove screws (7) and lockwashers (8) and

750 ohms to 250 ohms. Repeat this procedure using

carefully lift cover and situate at angle to prevent

the ohmmeter across pins M and N of the harness

potting compound from contacting variable resistors

plug. Disconnect actuator electrical connector before

and connectors.

making this measurement. Push actuator piston all

the way down and adjust engine speed with manual

CAUTION

throttle. If this value resistance is measured, check

sockets A and B at plug P-21 for 24 Vdc (A is posi-

Flash point of potting compound is 515F

tive).

(268. 3 C). Do not allow oven to reach

this temperature. The melting tempera~

(4) If the set is operating at a constant load

ture of potting compound is 165F (73.8 C).

and voltage and during an eight-hour period the change

in ambient temperature does not exceed 60 F, the

set frequency should not drift beyond 1/2 of one per-

cent of rated frequency. The above requirement as-

(3) Place governor control unit in oven and

sumes that the set temperatures were stabilized

bake at +180F to 185F (+82.2 C to +85 C) for 11 to

at the initial and final ambient temperatures.

12 hours.

4-22