TM 5-6115-465-12

TO 35C2-3-446-1

NAVFAC P-8-625-12

TM 06858B/06859D-12

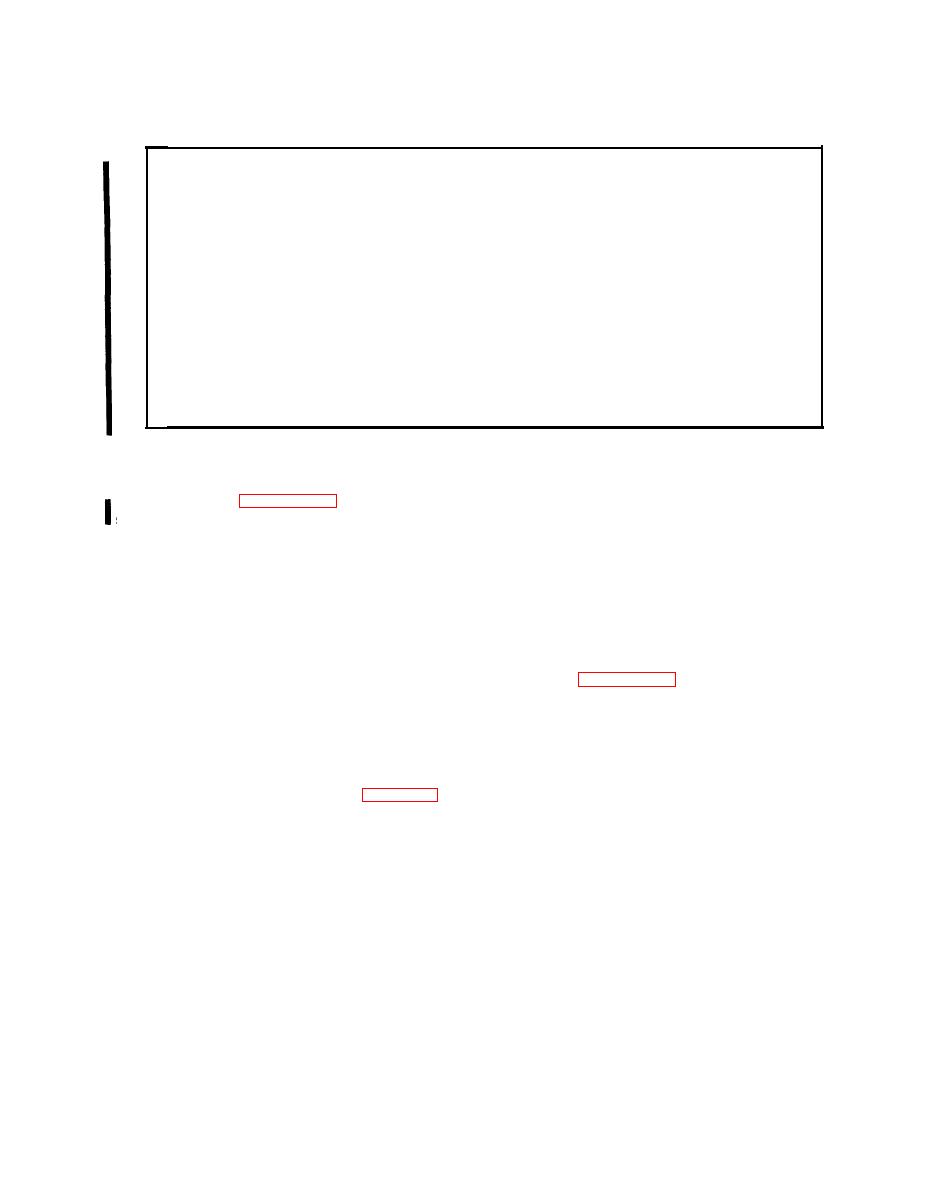

19. Tooth lockwasher

1. Screw and assembled washer

20. Fuse holder assembly

2. Lockwasher

21. Cap

3. Screw and captive washer assy

22. Fuse

4. Cover plate

23. Fuse holder

5. Screw and captive washer assy

24. Panel

6. Indicator panel assembly

25. Screw and captive washer assy

7. Nut

26. Cover plate assy

8. Indicator light assembly

27. Screw and captive washer assy

9. Lens

28. Screw

10. Lamp

29. Lockwasher

11. Base

30. Relay

12. Nut

31. Component board assembly

13. Tooth lockwasher

32. Cover plate

14. Test or reset switch

33. Screw and captive washer assy

15. Capacitor

34. Wiring harness

16. Nut

35. Housing

17. Positioning washer

18. Nut

Figure 39A Fault Locating Indicator, Exploded View (Sheet 2 of 2)

(b) Remove nut and lockwasher, screw, and

(3) Refer to paragraph 2-10 and start the generator

clip.

set.

(c) Remove nut and washer to remove manual

(4) Use the manual speed control to set generator

speed control cable assembly and grommet.

output frequency.

(d) Do not remove screws, lockwashers, and

(5) Rotate the control knob 90 degrees. Frequency

mounting bracket unless inspection revealed damaged.

change shall not exceed 1 percent for a 90 degree rotation

(0.6 Hz for 50/60 Hz generator sets and 4 Hz for 400 Hz

NOTE

generator sets).

See paragraph 3-59 for emergency conversion

(6) Replace manual speed control if it fails any of

from tactical precise to tactical utility and

the above tests or inspections.

for reconfiguration back to tactical precise.

c. Replacement.

(2) Cleaning.

(1) Removal.

(a) Clean all metal manual speed control parts

(a) Loosen adjustment screw (figure 3-40) and

in an approved solvent and dry thoroughly.

remove cable from sleeve.

3-81

Change 12