TM 5-6115-465-12

TO 35C2-3-446-1

NAVFAC P-8-625-12

TM 06858B/06859D-12

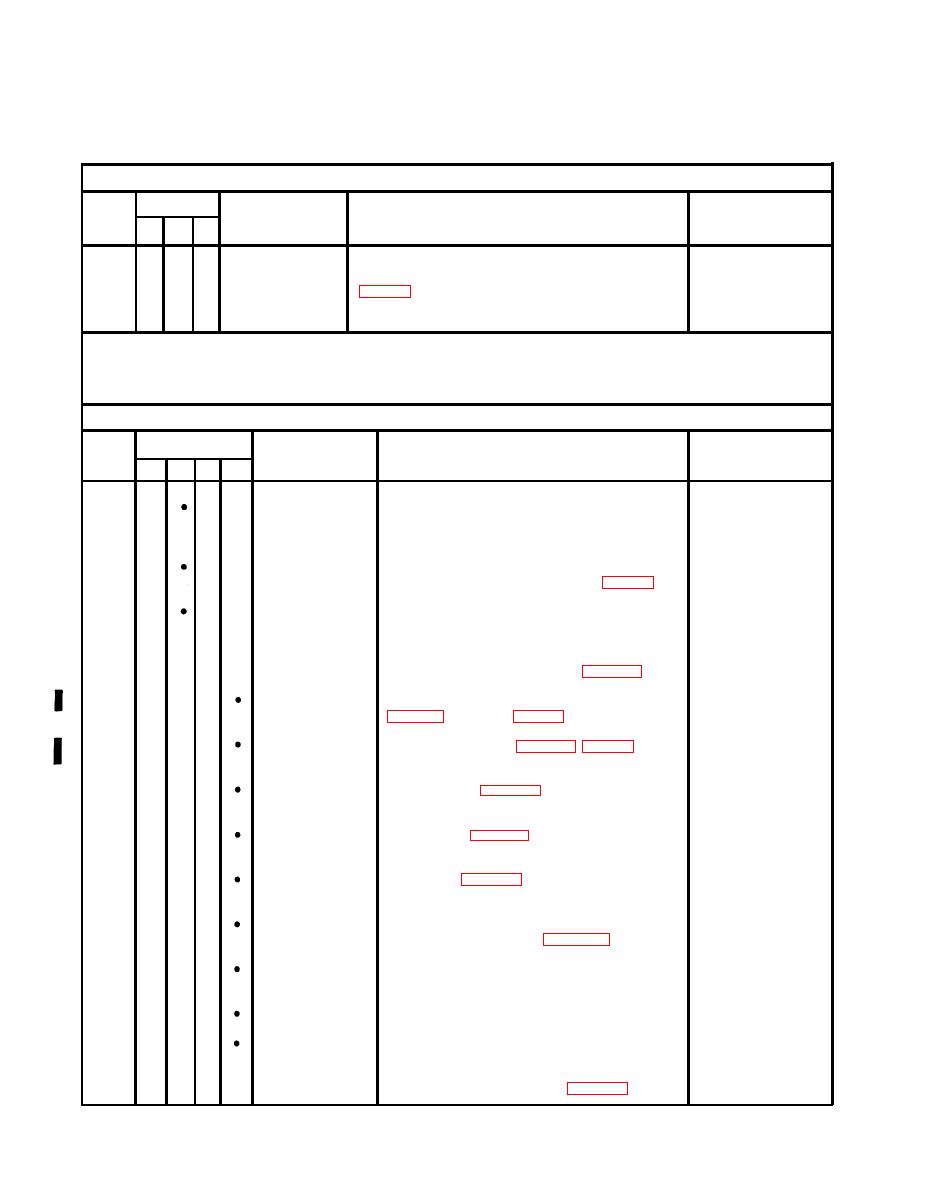

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

D-During Operation

A-After Operation

B-Before Operation

Equipment is not

Interval

Procedures: check for and have repaired or

Item

Item to be

adjusted as necessary.

Ready/Available if:

Inspected

No.

B

D

A

All doors and panels should seal and fit properly

11

suppression kit

H-Hours (as indicated)

M-Monthly (100 hours)

S-Semiannual (500 hours)

W-Weekly (40 hours)

Equipment is not

Item

Interval

Item to be

Procedures: Check for and have repaired or

Ready/Available if:

Inspected

adjusted as necessary.

No.

H

W

M

S

Check entire unit for missing, loose, or damaged

1

Generator Set

parts and hardware, and for unusual wear or

Check electrolyte level. Check condition with a

2

Batteries

hydrometer. Add water as required (para 3-8).

Inspect for worn, frayed, cracked, or oil-soaked

V-Belt

3

belt. Check adjustment. If adjustment is

required, adjust for a 1/2-inch deflection when

belt is depressed at a point midway between

alternator and water pump puny (para 3-90).

4

Fuel Filters

Replace filter elements every 100 hours

4A

Fuel Pump

Service every 100 hrs (para 3-78, fig. 3-17)

Strainers

Drain and refill (para 3-97). (MEP-104A Precise

5

Hydraulic Sump

Sets only)

Replace filter (para 3-97). (MEP-104A Precise

6

Hydraulic Filter

Sets only)

Hydraulic

Clean filter (para 3-98). (MEP 104A Precise Sets

7

only)

Actuator Screen

Inspect for damage. Clean breather and breather

8

Breather and

tube at oil change interval (para 3-103).

Breather Tube

Change every 300 hours or 6 months; in absence

Engine Oil

9

of the Army Oil Analysis Program (AOAP).

Change every 300 hours or 6 months.

10

Oil Filters

Air cleaner missing

11

Air Cleaner

This unit is equipped with an air filter condition

or unserviceable.

indicator light that will indicate when filter

element needs cleaning. Clean element when

necessary as indicated by light (para 3-24).

Change 16

3-8