T O 35C2-3-442-2

P-8-627-34

TM 5-6115-457-34

TM-07464A-35

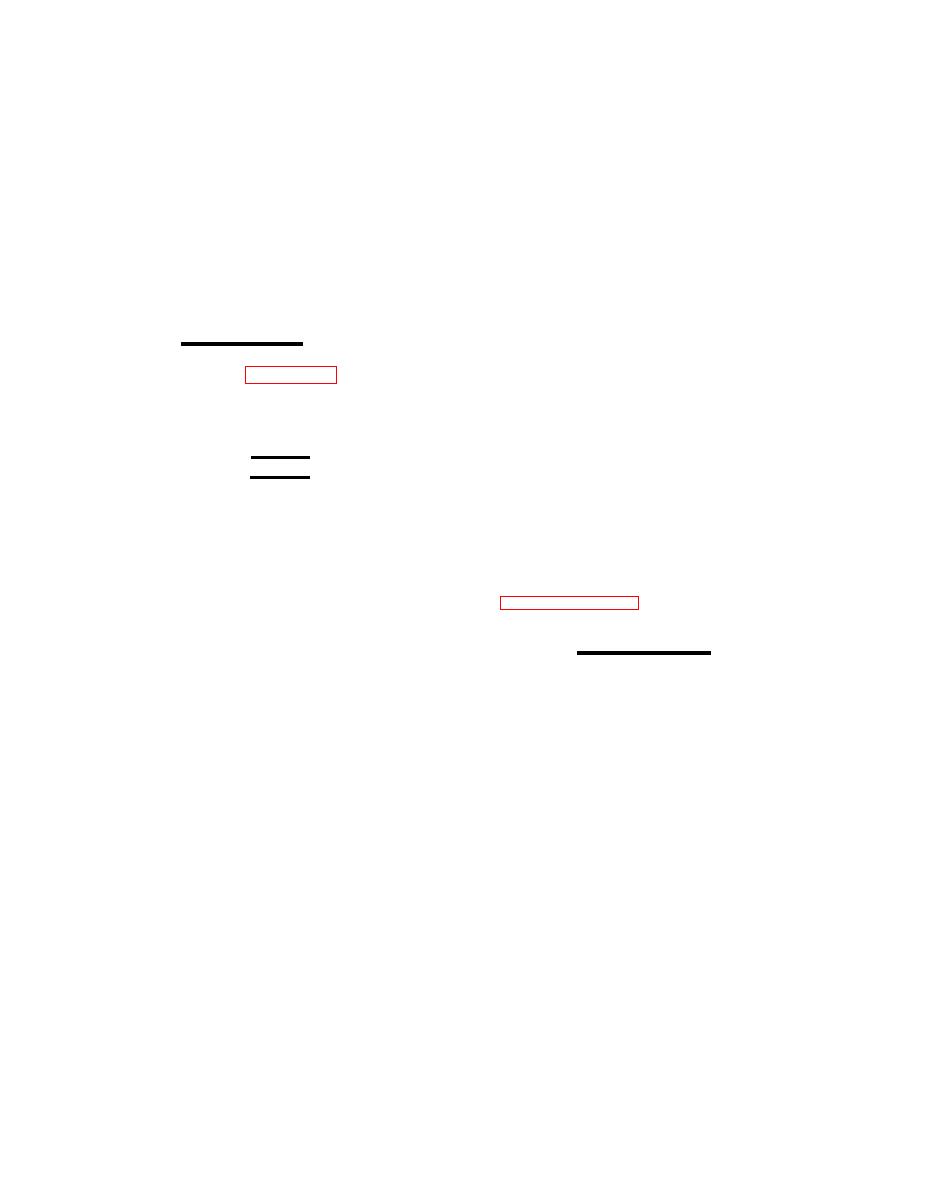

Legend to figure 12-6:

10.

Setscrew

1.

Nameplate

19.

Brush and spring assembly (2)

2.

Plug

20.

Wire

11.

Rotor

21.

Shell

3.

Relief valve spring

12.

Packing

4.

Relief valve ball

22.

Shell

13.

Adapter

5.

Screw (4)

23.

Motor

14.

Seal cage

6.

Port plate

24.

Screw (4)

15.

Packing

7.

Packing

25.

Plate

16.

Washer

8.

Cam ring

17.

Seal spring

26.

Gasket

9.

Blade (4)

27.

Capacitor

18.

Brush cap (2)

12-24.

d. Position spring (17), washer (16),

REASSEMBLY.

packing (15), seal cage (14), adapter (13),

and assembled rotor (11) on motor shaft.

Refer to figure 12-6 and reassem-

Align motor setscrew opening with flat of

ble the coolant pump in the reverse order

of index numbers assigned. Pay particular

motor shaft. Slide components toward

attention to the following:

motor, compressing spring (17) and install

setscrew (10).

WARNING

e. Install remaining components.

Avoid breathing fumes generated by

Tighten screws (5) evenly to prevent side

unsoldering/soldering. Eye pro-

tection is required.

loading components.

a. Solder wire (20) to motor and posi-

f. Test coolant pump as specified in

tion shell (22) on motor to ensure water

tight seal.

INSTALLATION.

12-25.

b. Apply a thin film of grease to pack-

Refer to Operator and Organiza-

ings (7, 12, and 15) and seal cage (14) so

tional Maintenance Manual and install

that packing will move in groove to form

coolant pump.

proper seal at time of reassembly. Posi-

ti on packings in grooves.

c. Install blades (9) in rotor (11).

Align alignment marks.

12-11/(12-12 blank)