T.O. 35C2-3-442-2

P-9-TM-457-35

TM 5-6115-457-34

TM-0746A-35

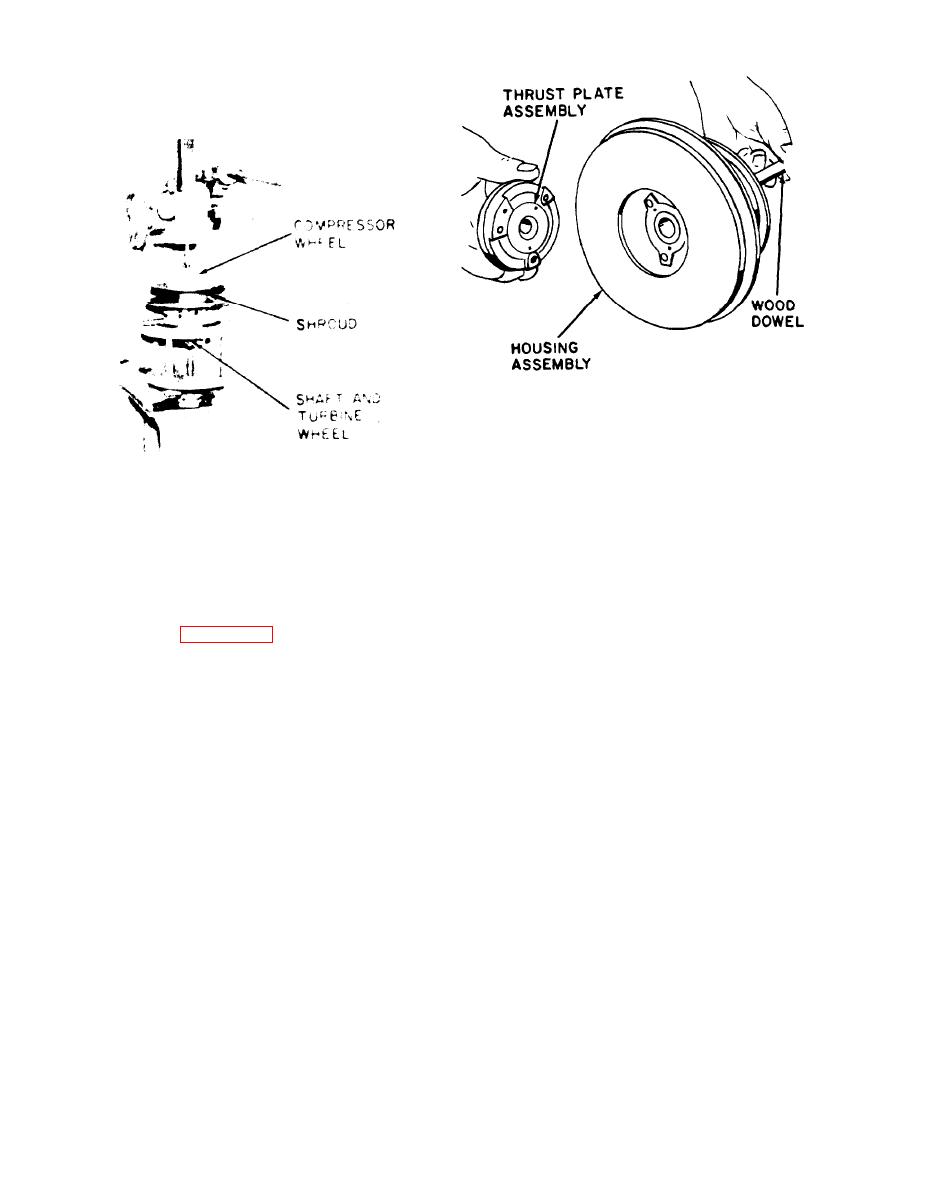

Figure 8-18.

Removing thrust Plate

3. Remove wheel (48) from oil bath,

and immediately install wheel on shaft,

install old nut (47) and tighten to 120 inch

Figure 8-17. Pressing shaft and turbine

pounds torque.

wheel from compressor wheel

4. Allow wheel to cool to less than

8-75. REASSEMBLY.

150 F and remove nut (47).

Refer to figure 8-16, and reassem-

5. Using lubricating oil MIL-L-

ble turbocharger group in the reverse order

2104, lightly lubricate the threads of

of index numbers assigned. Pay particular

turbine shaft and a new nut (47).

attention to the following:

6. Install new nut (47) and tighten

a. Torque screw (52) from 30 to 40

to 20 inch pounds torque, then tighten an

inch pounds.

additional 120 degrees.

b. Install collar (55) so oil hole aligns

7. Coat threads of bolts (2 places)

with oil hole in housing (65).

(42) with an approved anti-seize compound.

Install both and tighten from 160 to 180

c. Install wheel (48) on shaft and wheel

inch pounds torque.

assembly (60) as follows:

1. Place the shaft and wheel assem-

bly end of center housing (65) in turbine

8-76.

INSTALLATION.

fixture.

2. Place wheel (48) in an oil bath,

Refer to Operator and Organizational

Maintenance Manual, and install the turbo-

heat wheel to a maximum of 350 F for no

charger group.

longer than 10 minutes.

8-40