P-9-TM-457-35

T.0. 35C2-3-442-2

TM-07464A-35 TM 5-6115-457-34

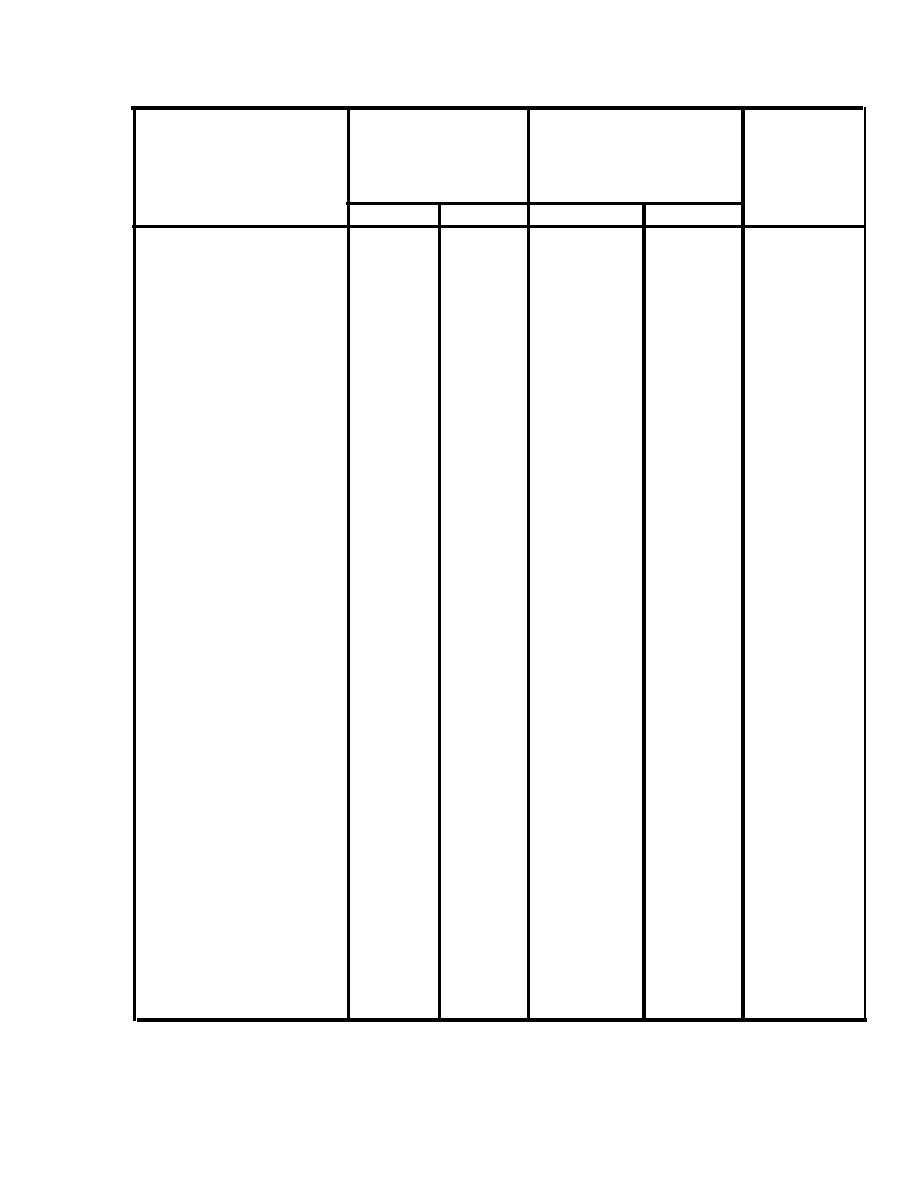

Repair and Replacemment Standards (continued)

Table 1-1.

MANUFACTURER'S

MAXIMUM

DIMENSIONS AND

ALLOWABLE

TOLERANCES

WEAR AND

COMPONENT

DESIRED CLEARANCE

IN INCHES

CLEARANCE

MIN

MAX

MIN

MAX

Connecting Rods:

1.7009

1.7012

Pin bearing bore

0.006

9.594

9.596

Center to center length

3.2495

3.2505

B o r e in rod forbearing

1.6997

1.7000

P i n diameter

Crankshaft journal

3.002

bearing bore

3.006

0.010

Piston Group:

Top ring to groove

clearance

0.0028

0.0046

0.006

Intermediate ring to

0.0023

g r o o v e clearance

0.0041

0.006

Oil control ring to groove

0.0015

clearance

0.0033

0.006

1.6999

1.7001

0.006

Pin bore

Ring gap measured in

unworn portion of liner

bore size 4.750 in. **

0.017

0.023

Top ring

0.017

0.023

I n t e r m e d i a t e ring

0.013

0.023

Oil control ring

`*Increase in ring gap

for each 0.001 in

increase in liner

0.003

bore

1-37