TM 5-6115-400-35

95-105 ft. lbs. Determine the

amount of shimming washers

necessary to fill the gap between

ends of the bracket and cap.

(e) Remove capscrews and install

shimming washers to equal the gap.

Note. Shimming washers are 1/32

inch thick and must be evenly

distributed on both sides of bracket.

(f) Reinstall capscrew and torque to

95-105 ft. lbs.

Note. The bracket assembly must

be a tight fit on trunnion to avoid

"bearing out" the liners.

c. Timing Gear Housing Cover.

(1) Removal.

(a) Remove crankshaft pulley/vibration

damper (para 47).

(b) Remove engine front mounting

bracket.

(c) Remove fan, fan hub, and fan hub

mounting bracket.

(d) Remove water pump pulley, water

pump belt idler, and idler support

bracket, and filler pipe support.

(e) Remove capscrews securing the oil

pan to timing gear housing cover.

To facilitate removal and installation

of timing gear housing cover, it is

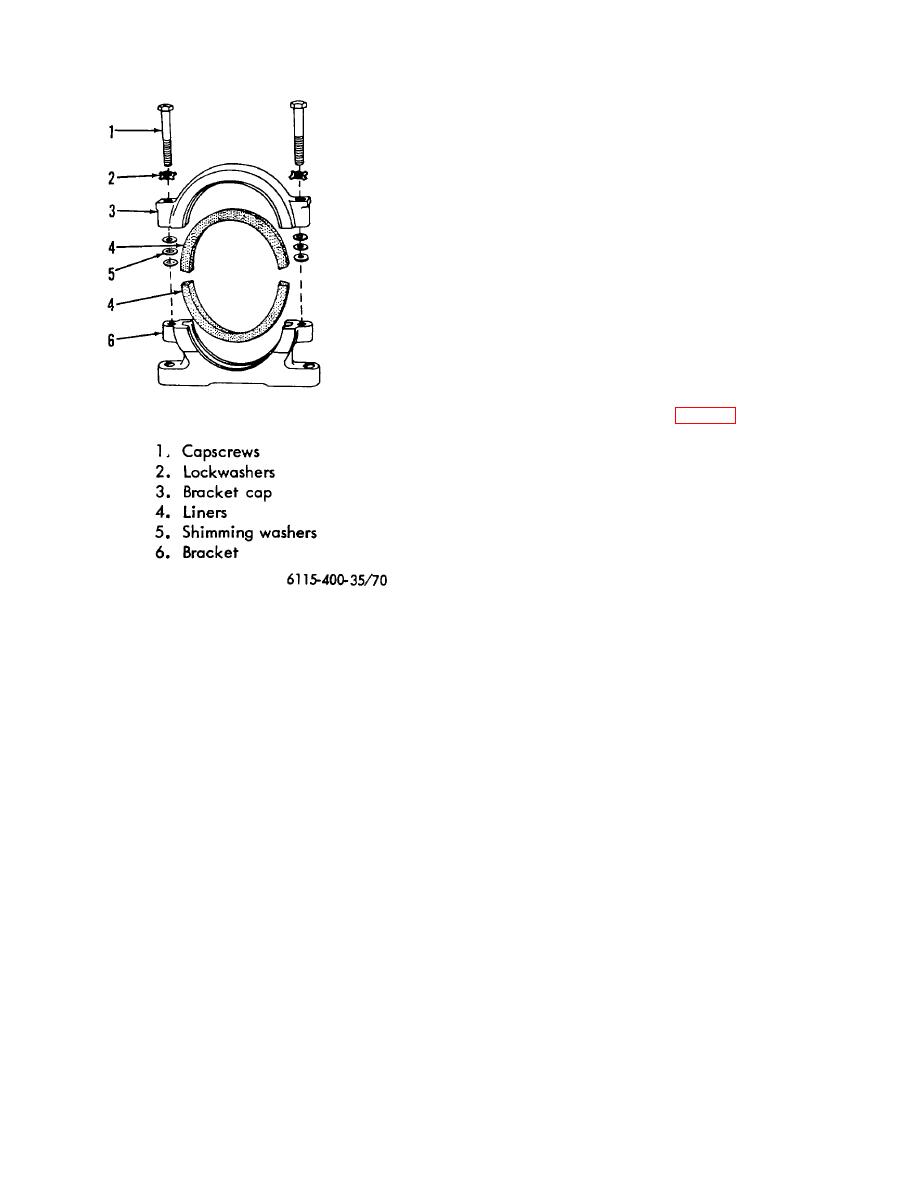

Figure 70. Engine front mounting bracket-with

possible to loosen the oil pan

liners.

capscrews enough to lower front

end of the oil pan; however, it is

(b) Remove the old liners and carefully

recommended that the oil pan be

clean the grooves in the bracket

removed and all gaskets replaced.

and cap.

(f) Remove capscrews securing timing

(3) Installation.

gear housing cover to timing gear

(a) Install new liners, making certain

housing and jar cover loose with a

that the liner ends are flush with the

soft-headed hammer; pry cover

ends of the grooves in bracket and

from locating dowels and remove it

cap.

from engine being careful not to

damage front portion of oil pan

(b) Install bracket on frame. Install

gasket.

bracket securing hardware-do not

tighten at this time.

(2) Installation.

(c) Lower engine into position on

(a) Before installing cover, install a new

bracket and install bracket cap and

crankshaft front oil seal (refer to

securing capscrews.

para d. following).

(d) Tighten bracket cap securing

(b) Remove burrs from keyway in

capscrews evenly to a torque of

crankshaft, using a fine-cut mill

104